Electrode used for elastic clamping jaw, machining method and application

A technology of elastic jaws and processing methods, applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve problems such as inability to guarantee deformation requirements, small heat-affected range of materials, and short duration of pulse discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the concept of the present invention, the specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings:

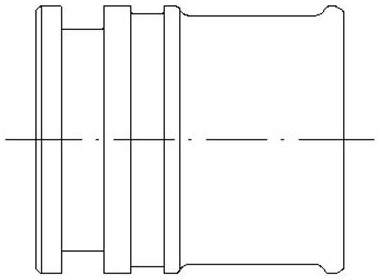

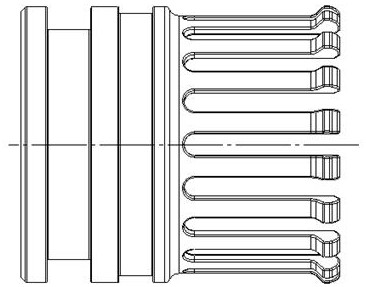

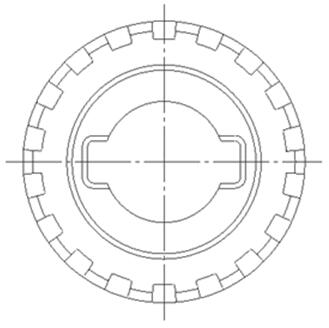

[0024] Such as Figure 4 with Figure 5 As shown in the present invention, an electrode for elastic jaws, the electrode includes a processing electrode 1 and a connecting electrode 2 arranged at the top of the processing electrode 1 for connection, and arranged at the bottom of the processing electrode 1 for The supported supporting electrode 3, the processing electrode 1, the connecting electrode 2 and the supporting electrode 3 are all arranged in a cylindrical structure, wherein the connecting electrode 2 and the supporting electrode 3 are coaxially distributed on both sides of the processing electrode 1. The outer surface of the processing electrode 1 is provided with a plurality of annularly distributed electrode teeth 11 along its circumference, and a refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com