Multi-material electric discharge machining electrode and its machining method

A processing method, EDM technology, applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of low processing efficiency, cumbersome tool trajectory planning strategy, frequent electrode replacement, etc., to improve surface quality and avoid machining The effect of low efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

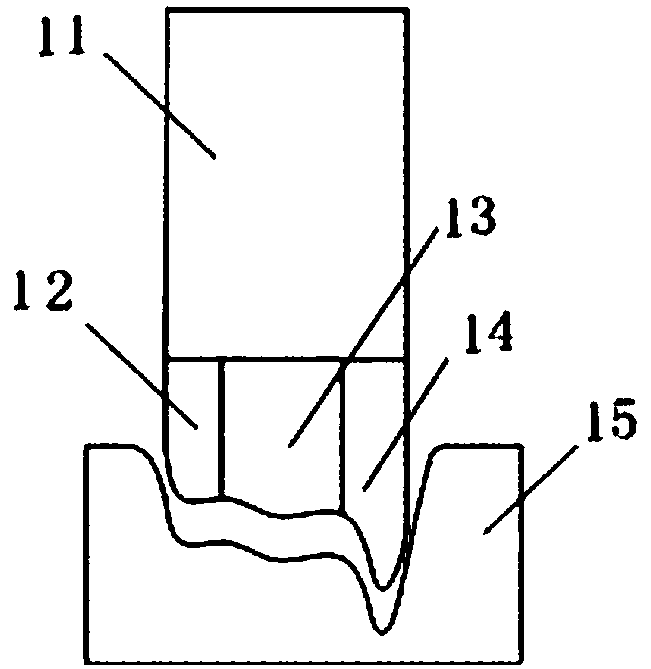

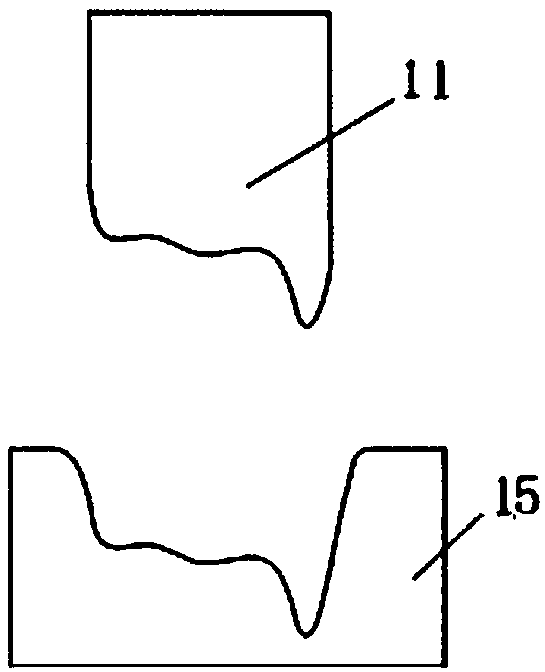

[0070] Example 1, such as Figure 1-1 to Figure 1-3 As shown, a multi-material electric discharge machining electrode includes a first electrode base body 11 and a component electro-erosion material arranged at the bottom of the first electrode base body 11; there are more than one type of electro-erosion material to form the component electro-erosion material, and The degree of resistance to electric corrosion is different among various electric corrosion materials, and the degree of electric corrosion resistance between the electric corrosion material and the first electrode base 11 is different.

[0071] The component electro-corrosion materials include the first electro-corrosion material I12, the first electro-corrosion material II13 and the first electro-corrosion material III14, the first electro-corrosion material I12, the first electro-corrosion material II13 with different degrees of electro-corrosion resistance and the first electro-etching material III14 are arrang...

Embodiment 2

[0075] Example 2, such as Figure 2-1 to Figure 2-3 As shown, a multi-material electric discharge machining electrode includes a second electrode base body 21 and a component electro-erosion material arranged at the bottom of the second electrode base body 21; the electro-erosion material forming the component electro-erosion material has more than one type, and The degree of resistance to electric corrosion is different among various electric corrosion materials, and the degree of electric corrosion resistance between the electric corrosion material and the second electrode base 21 is different.

[0076] When the component electroerosion material is a separate second electroerosion material 22, the second electrode matrix 21 and the second electroerosion material 22 are cylinders, and the diameter of the top surface of the second electroerosion material 22 is smaller than the bottom surface of the second electrode matrix 21 diameter of.

[0077] The component electroerosion ...

Embodiment 3

[0079] Example 3, such as Figure 3-1 to Figure 3-4 As shown, a multi-material electric discharge machining electrode includes a third electrode base body 31 and a component electro-erosion material arranged at the bottom of the third electrode base body 31; the electro-erosion material forming the component electro-erosion material has more than one type, and The degree of resistance to electric corrosion is different among various electric corrosion materials, and the degree of electric corrosion resistance between the electric corrosion material and the third electrode base 31 is different.

[0080] When the component electroerosion material includes a third electroerosion material I32 and a third electroerosion material II33, the third electroerosion material I32 includes a hexagonal prism part 321 and a cuboid part 322 arranged on one side wall of the hexagonal prism part 321, and the third electroerosion material The etching material II 33 is a cylinder, and is disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com