Suction specific gravity sieve and blown specific gravity sieve combined grain selection machine

A combined and concentrating machine technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve the problems of poor cleaning efficiency and precision, mechanical displacement, and screening Poor effect and other problems, to achieve the effect of screening effect and screening output improvement, slight mechanical shaking, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

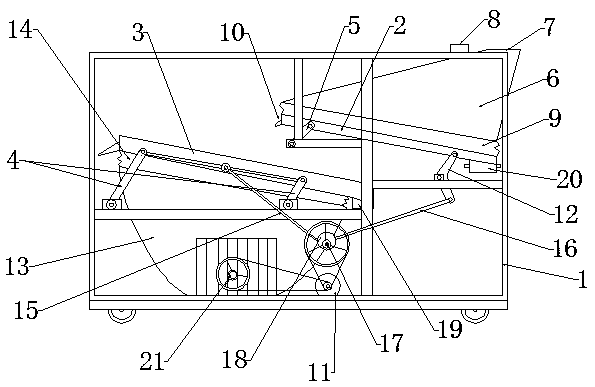

[0030] combined with Figures 1 to 61. The grain classifying machine comprises a frame 1, a suction gravity screen, a blowing gravity screen, a driving device 11, a support arm and a reversing device. The front and bottom of the frame 1, the front part of the suction specific gravity screen overlaps with the rear part of the blowing specific gravity screen in the front and rear direction; , flexible sealing belt 9 and miscellaneous box 20, the air suction specific gravity table 2 is inclined to be set in a high front and low rear mode, and the box body 6 is arranged on the top of the air suction specific gravity table 2, and between the box body 6 and the air suction specific gravity table 2 is provided with A flexible sealing strip 9, a feed pipe 8 is arranged at the middle and rear position above the box body 6, an air exhaust port 7 is arranged at the rear part of the box body 6 above the back and upper part of the suction specific gravity table 2, and an air suction port 7...

Embodiment 2

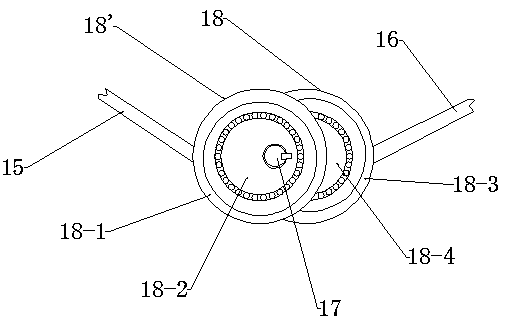

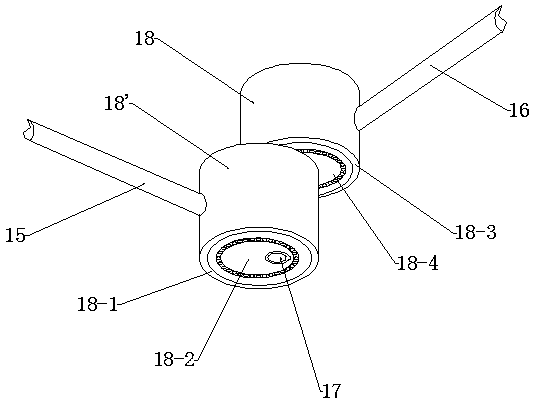

[0034] combined with figure 2 and attached image 3 The eccentric bearing inner ring 18-4 of the air suction specific gravity table and the eccentric bearing inner ring 18-2 of the air blowing specific gravity table are both dislocated and socketed on the drive shaft 17. The misalignment of the eccentric bearing 18 of the suction specific gravity table and the eccentric bearing 18' of the blowing specific gravity table can be adjusted. After adjustment, the drive shaft 17 and the inner ring of the eccentric bearing of the suction specific gravity table 18-4, and the inner ring of the eccentric bearing of the blowing specific gravity table 18-2 can be fixed. , then the highest and lowest relative displacements between the eccentric bearing 18 of the suction specific gravity table and the eccentric bearing 18' of the blowing specific gravity table are determined. The distance between the center of the circle has gone through the maximum distance and the minimum distance, and t...

Embodiment 3

[0036] combined with Figure 4 , 5 and attached Image 6 , the inner ring 18-4 of the eccentric bearing of the suction specific gravity table and the inner ring 18-2 of the eccentric bearing of the blowing specific gravity table are matched and fixed, and the drive shaft 17 is sleeved on the inner rings of the two eccentric bearings. The eccentric bearing 18 of the specific gravity table and the eccentric bearing 18' of the air blowing specific gravity table have the same circle center, and there is no displacement between them. One end of the rod 15 is fixedly connected to the eccentric bearing jacket 18-1 of the air blowing specific gravity table, and the other end of the driving rod 16 of the suction specific gravity table is movably connected to the reversing arm 12, and the reversing arm 12 is movably connected to the suction specific gravity table 2, and the blowing specific gravity table is driven The other end of the rod 15 is movably connected to the blowing specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com