Preparation and application of magnetic ferric oxide/ammonium phosphomolybdate porous composite material

A porous composite material, magnetic iron oxide technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, inorganic chemistry, etc., can solve the problem of iron tetroxide mosaic ammonium phosphomolybdate polyhedral crystal preparation method has not been reported and other problems, to achieve the effect of good magnetic separation characteristics, high degree of crystallization, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

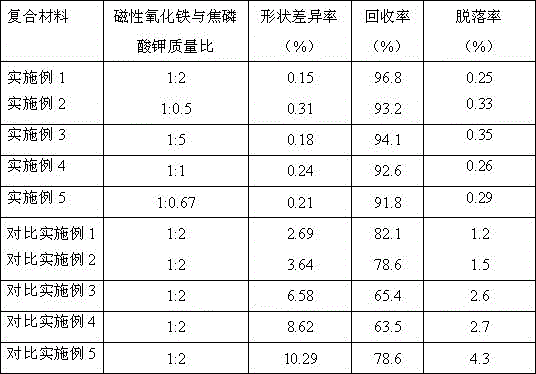

Embodiment 1

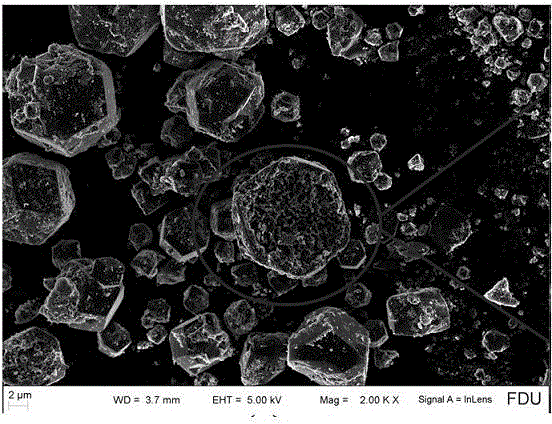

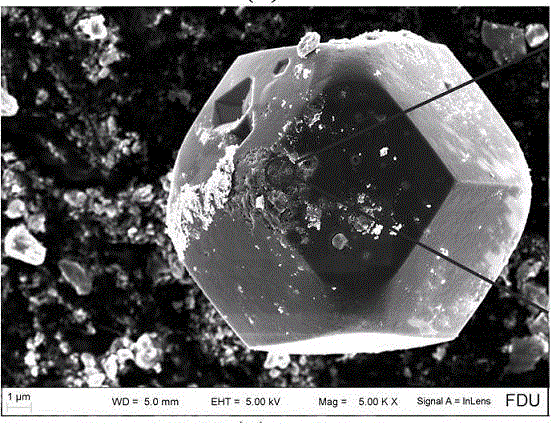

[0031] Embodiment 1 A kind of preparation method of magnetic iron oxide / ammonium phosphomolybdate porous composite material

[0032] Described preparation method specifically comprises the following steps:

[0033] (1) Ultrasonic dispersion of 0.5 g superparamagnetic 10 nm magnetic iron oxide nanoparticles into 500 mL 2 M HNO 3 In the solution, stir evenly and let it stand for 35 min, wash the magnetic particles with deionized water three times, and then ultrasonically disperse them into 200 mL of deionized water, add 80 mL of 135.9 mM ammonium molybdate solution to it under mechanical stirring conditions, continue After stirring for 15 min, the intermediate solution 1 was obtained.

[0034] (2) Accurately measure 2.5 ml of concentrated nitric acid, slowly add it to 17.5 ml of deionized water, shake well, add 1.0 g of potassium pyrophosphate to it, stir to dissolve, and obtain intermediate solution 2.

[0035] (3) Under the condition of mechanical stirring, the reaction temp...

Embodiment 2

[0036] Embodiment 2 A kind of preparation method of magnetic iron oxide / ammonium phosphomolybdate porous composite material

[0037] Described preparation method specifically comprises the following steps:

[0038] (1) Ultrasonic dispersion of 0.2g superparamagnetic 8nm magnetic iron oxide nanoparticles into 500 mL 2 M HNO 3 In the solution, stir evenly and let it stand for 30 min, wash the magnetic particles with deionized water for 4 times, and then ultrasonically disperse them into 200 mL of deionized water, add 80 mL of 135.9 mM ammonium molybdate solution to it under mechanical stirring conditions, continue After stirring for 10 min, intermediate solution 1 was obtained.

[0039] (2) Accurately measure 4 ml of concentrated nitric acid, slowly add it to 16 ml of deionized water, shake well, add 1.0 g of potassium pyrophosphate to it, stir to dissolve, and obtain intermediate solution 2.

[0040] (3) Under the condition of mechanical stirring, the reaction temperature is ...

Embodiment 3

[0041] Embodiment 3 A kind of preparation method of magnetic iron oxide / ammonium phosphomolybdate porous composite material

[0042] Described preparation method specifically comprises the following steps:

[0043] (1) Ultrasonic dispersion of 0.2 g superparamagnetic 12 nm magnetic iron oxide nanoparticles into 500 mL 2 M HNO 3 In the solution, stir evenly and let it stand for 40 min, wash the magnetic particles with deionized water three times, and then ultrasonically disperse them into 200 mL of deionized water, add 80 mL of 135.9 mM ammonium molybdate solution to it under mechanical stirring conditions, continue Stir for 20 min to obtain intermediate solution 1.

[0044] (2) Accurately measure 2 ml of concentrated nitric acid, slowly add it to 18 ml of deionized water, shake well, add 1.0 g of potassium pyrophosphate to it, stir to dissolve, and obtain intermediate solution 2.

[0045] (3) Under the condition of mechanical stirring, the reaction temperature is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com