Method for obtaining oil absorption material by adopting melamine resin foam as matrix

A technology of melamine resin and oil-absorbing materials, which is applied in the field of oil pollution treatment, can solve the problems of further improvement of oil absorption rate and magnification, and achieve the effects of significant production cost and environmental protection, low density and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a method for obtaining an oil-absorbing material based on melamine resin foam, comprising the following steps:

[0030] (1) Take the melamine resin foam, put it into the hydrophobic agent solution, and vacuum impregnate it at 80°C for 40 minutes;

[0031] (2) Take out the melamine resin foam containing the hydrophobic agent and perform rapid drying to obtain an oil-absorbing material based on the melamine resin foam.

[0032] The water-repellent agent solution is an ethanol solution of octadecyltrimethyloxysilane, and the weight ratio of octadecyltrimethyloxysilane to ethanol is 2:55.

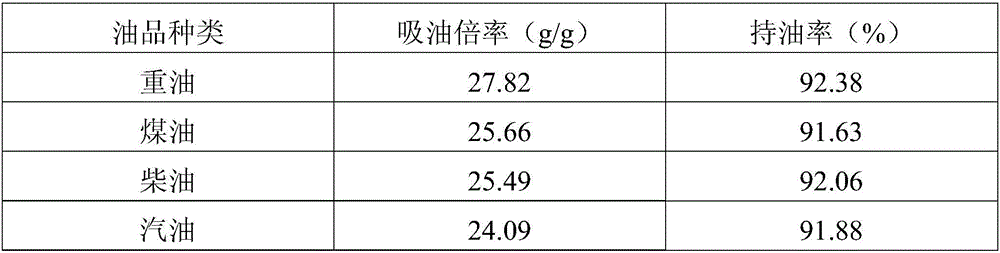

[0033] Determination of the absorption rate and oil retention rate of the oil-absorbing material obtained in this embodiment in diesel oil and water is as follows:

[0034]

[0035]

Embodiment 2

[0037] The present embodiment provides a method for obtaining an oil-absorbing material based on melamine resin foam, comprising the following steps:

[0038] (1) Take the melamine resin foam, put it into the hydrophobic agent solution, and vacuum impregnate it at 25°C for 60 minutes;

[0039] (2) Take out the melamine resin foam containing the hydrophobic agent and perform rapid drying to obtain an oil-absorbing material based on the melamine resin foam.

[0040] The water-repellent agent solution is an ethanol solution of octadecyltrimethyloxysilane, and the weight ratio of octadecyltrimethyloxysilane to ethanol is 1:50.

[0041] Determination of the absorption rate and oil retention rate of the oil-absorbing material obtained in this embodiment in diesel oil and water is as follows:

[0042] Oil type

Embodiment 3

[0044] The present embodiment provides a method for obtaining an oil-absorbing material based on melamine resin foam, comprising the following steps:

[0045] (1) Take the melamine resin foam, put it into the hydrophobic agent solution, and vacuum impregnate it at 100°C for 20 minutes;

[0046] (2) Take out the melamine resin foam containing the hydrophobic agent and perform rapid drying to obtain an oil-absorbing material based on the melamine resin foam.

[0047] The water-repellent agent solution is an ethanol solution of octadecyltrimethyloxysilane, and the weight ratio of octadecyltrimethyloxysilane to ethanol is 5:60.

[0048] Determination of the absorption rate and oil retention rate of the oil-absorbing material obtained in this embodiment in diesel oil and water is as follows:

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com