Method for preparing rapid adsorption material with porous structure

A technology of adsorption material and porous structure, which is applied in the field of preparation of fast adsorption materials, can solve the problems of slow adsorption speed and lack of rigid molecular skeleton, and achieve fast adsorption speed, excellent adsorption capacity, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a fast-absorbing material with a porous structure, comprising the following steps:

[0050] (1) Preparation of oxidized cellulose

[0051] Mix sodium periodate and sodium chlorite and dissolve them in deionized water; add microcrystalline cellulose, adjust the pH value of the solution to 2 with dilute hydrochloric acid, and obtain a mixed solution; 3h; then add 10mL ethylene glycol to react for 30min to remove unreacted sodium periodate; finally, wash and dry to obtain oxidized cellulose;

[0052] The mass concentration of microcrystalline cellulose in the mixed solution is 10g L -1 , the mass concentration of sodium periodate is 20g L -1 , the mass concentration of sodium chlorite is 13.6g L -1 ;

[0053] (2) Preparation of adsorption material

[0054] Take 0.2g of oxidized cellulose prepared in step (1) and mix with 0.07g of tetrafluoroterephthalonitrile, 0.25g of potassium carbonate, and 0.034g of potassium hydroxide to obtain a mixture; a...

Embodiment 2

[0063] As described in Example 1, the difference is that the mass concentration of sodium periodate in the mixed solution of step (1) is 30g L -1 .

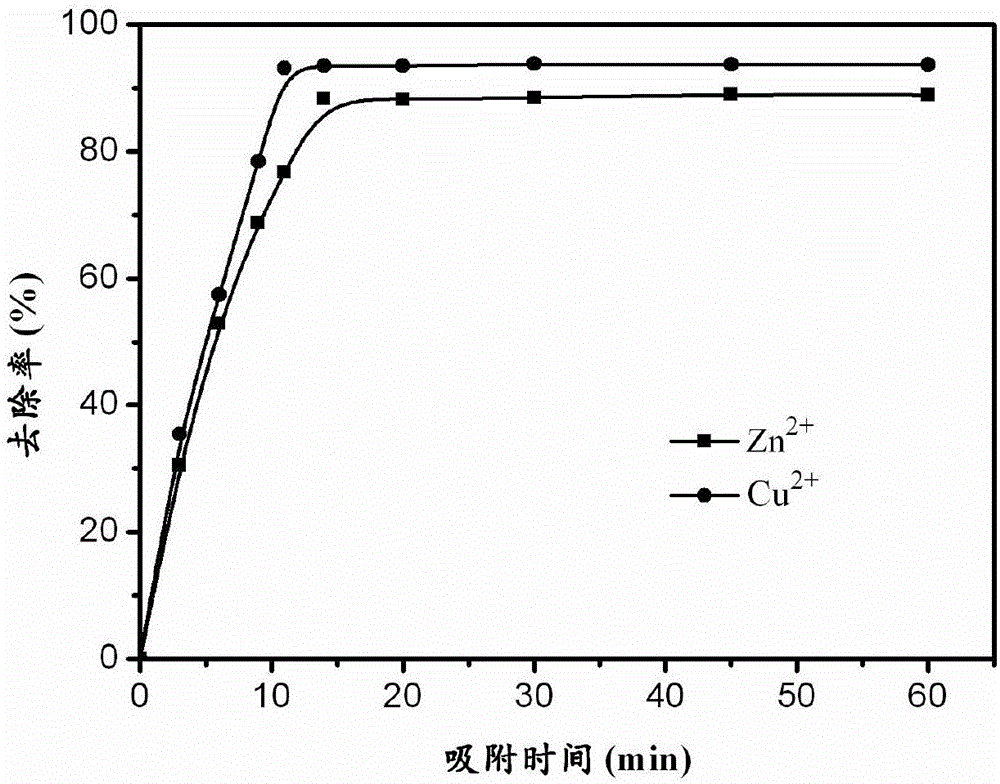

[0064] The adsorption material obtained in this example is at 10 mg·L -1 Cu 2+ The adsorption equilibrium time in the solution was 11min, and the removal rate was 93.7%; at 10mg L -1 Zn 2+ The adsorption equilibrium time in the solution was 14min, and the removal rate was 88.6%.

Embodiment 3

[0066] As described in Example 1, the difference is that the amount of tetrafluoroterephthalonitrile added in step (2) is 0.1 g.

[0067] The adsorption material obtained in this example is at 10 mg·L -1 Cu 2+ The adsorption equilibrium time in the solution was 10min, and the removal rate was 94.9%; at 10mg L -1 Zn 2+ The adsorption equilibrium time in the solution was 12min, and the removal rate was 89.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com