Laminated flexible battery and preparation method thereof

A flexible battery and laminated technology, applied in the field of lithium-ion batteries, can solve the problems of low space utilization and limited bending capacity of flexible structures, and achieve the effects of saving connection distance, good safety, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

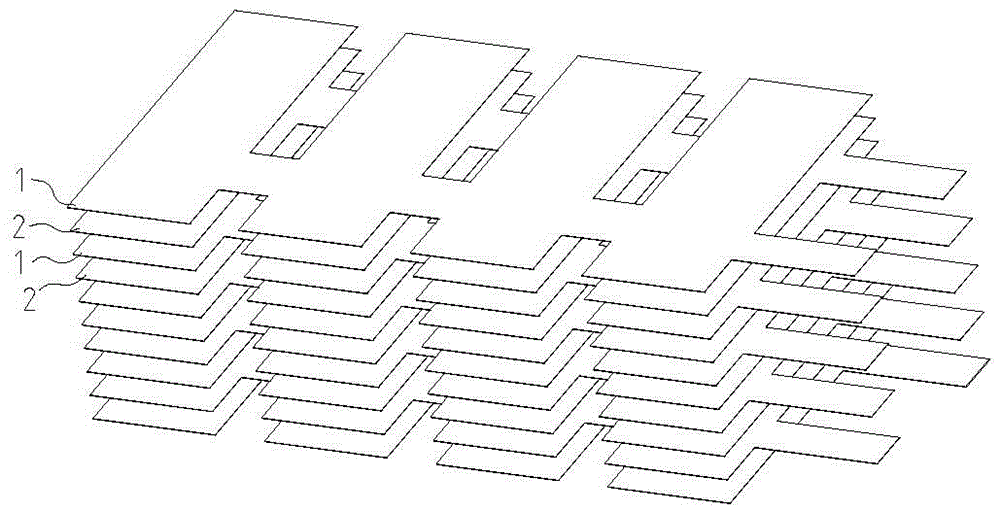

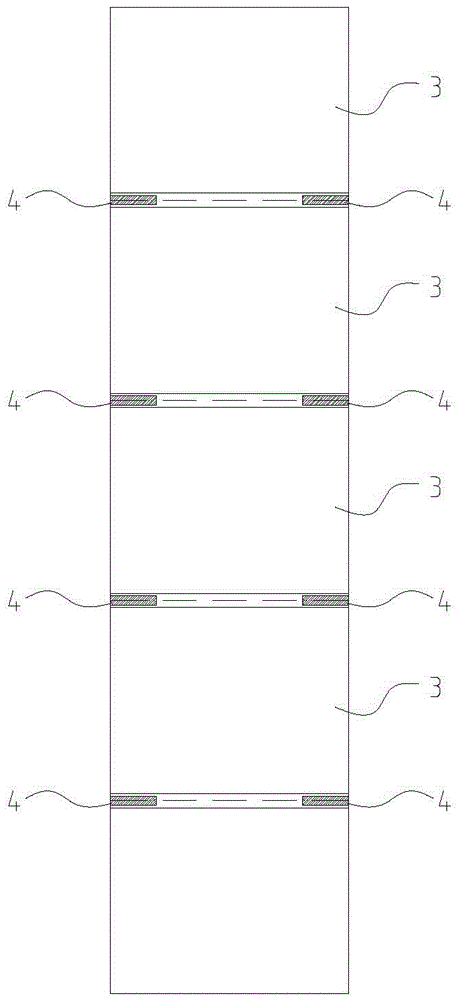

[0031] A laminated flexible battery includes a battery core formed by laminating positive pole pieces, negative pole pieces and separators, and an aluminum-plastic film wrapping the battery core. The separator is located between the positive pole piece and the negative pole piece, the head of the positive pole piece is welded with the positive pole lug, and the head of the negative pole piece is welded with the negative pole lug. The present invention is different from the traditional lithium-ion single battery except that the structure and production method of the positive electrode carrier fluid, the negative electrode carrier fluid, and the aluminum-plastic film are different, and the other battery manufacturing processes can be basically the same as the prior art.

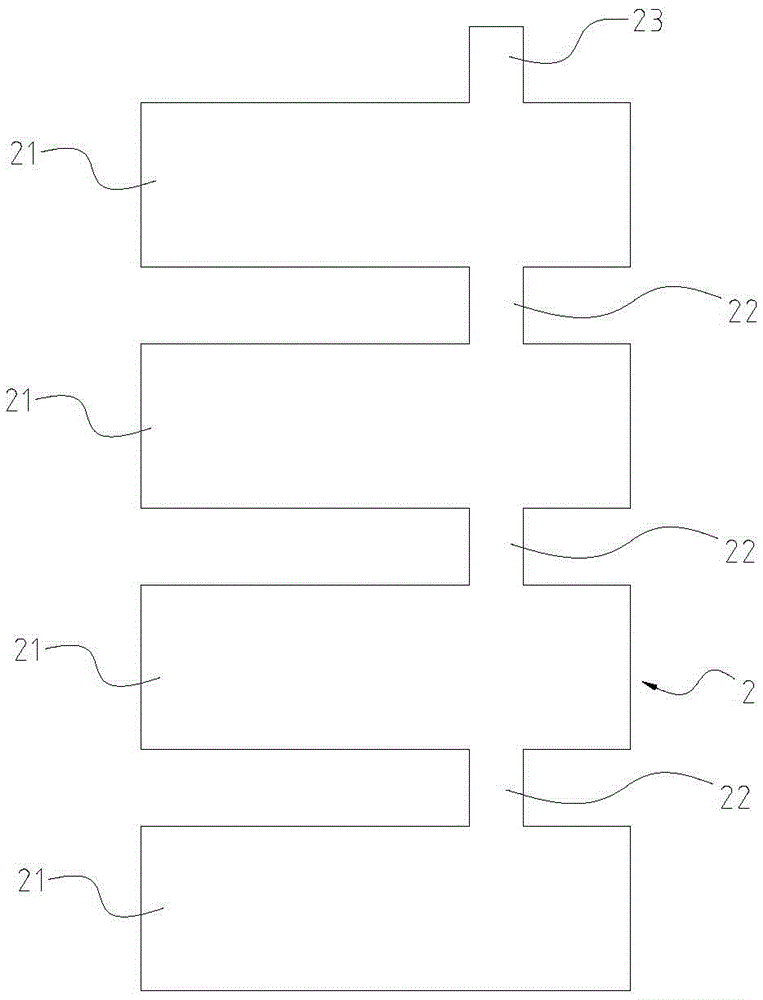

[0032] Such as figure 1 As shown, the positive electrode sheet includes a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com