Preparation method and application of self-healing-gel-coated hollow stannic oxide nano microsphere material

A nano-microsphere and self-healing technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, secondary batteries, electrochemical generators, etc., can solve the problems of ineffective volume expansion and easy agglomeration of nanostructures, and achieve Improved self-healing ability, uniform coating, and easy experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

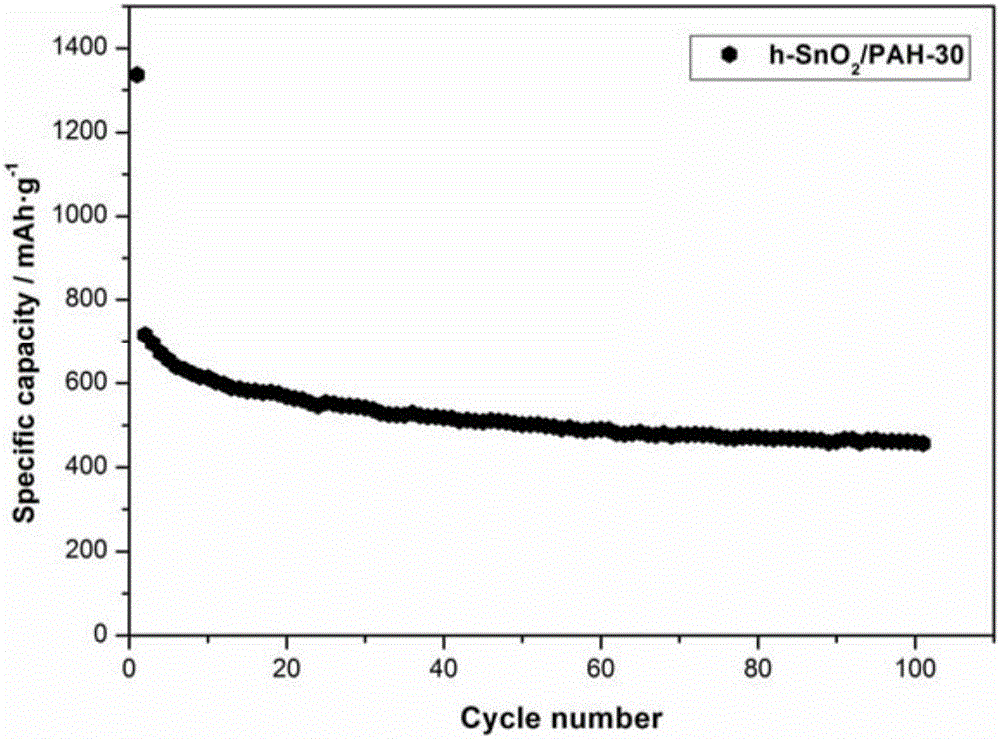

example 1

[0029] Take 0.1g of polyallylamine hydrochloride and 0.03g of phytic acid aqueous solution and add them in sequence to 10mL of the hollow tin dioxide suspension with a concentration of 20%, and use an ultrasonic machine to sonicate for 20min for thorough mixing. The pH value of the system was adjusted to 6-7 by dilute ammonia water and dilute hydrochloric acid, fully stirred at room temperature for 15 minutes, and the stirred product was left to stand at room temperature for 3 hours. After standing still, put it into a refrigerator to freeze at -20°C, and then use a lyophilizer to lyophilize to obtain phytic acid-crosslinked polyallylamine hydrochloride gel-coated hollow SnO2 nanometer microspheres.

[0030] It can be seen from the charge-discharge cycle test that the hollow SnO coated with 30% phytic acid-crosslinked polyallylamine hydrochloride gel 2 exhibits a relatively hollow SnO 2 High cycle performance of the microspheres, with a capacity of 316mAh g at the 70th cycle ...

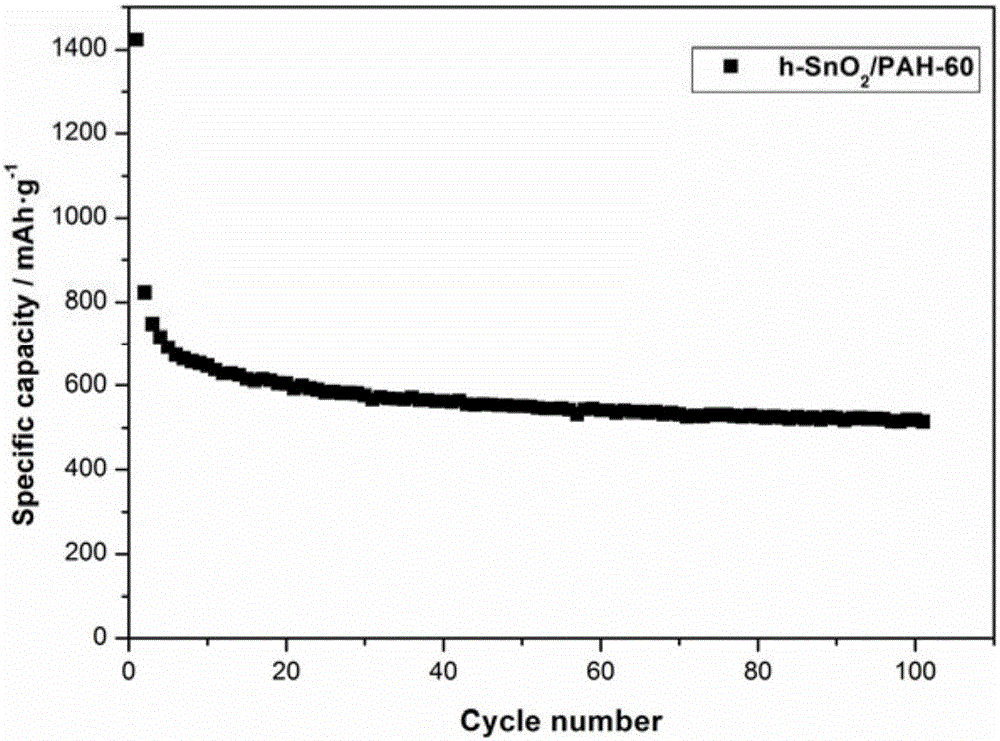

example 2

[0032] Take 0.1g of polyallylamine hydrochloride and 0.06g of phytic acid aqueous solution and add them in sequence to 14mL of hollow tin dioxide suspension with a concentration of 25%, and ultrasonically sonicate for 20min for thorough mixing. The pH value of the system was adjusted to 6-7 by dilute ammonia water and dilute hydrochloric acid, fully stirred at room temperature for 20 minutes, and the stirred product was left standing at room temperature for 4 hours. After standing still, put it into a refrigerator to freeze at -20°C, and then use a lyophilizer to lyophilize to obtain phytic acid-crosslinked polyallylamine hydrochloride gel-coated hollow SnO2 nanometer microspheres.

[0033] It can be seen from the charge-discharge cycle test that the hollow SnO coated with 60% phytic acid-crosslinked polyallylamine hydrochloride gel 2 It exhibits high cycle performance, and its capacity after the 100th cycle can be stabilized at 459mAh g-1 . This shows that when the dosage of...

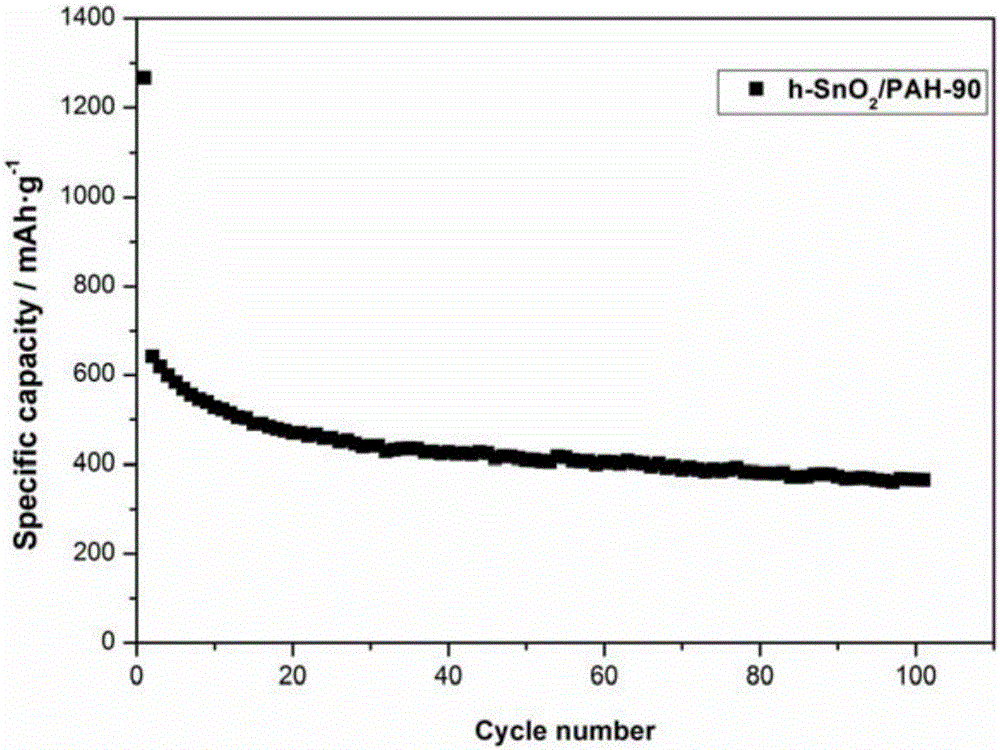

example 3

[0035] Take 0.1g of polyallylamine hydrochloride and 0.09g of phytic acid aqueous solution into 20mL hollow tin dioxide suspension with a concentration of 30% respectively in sequence, and mix thoroughly by ultrasonication for 20min. The pH value of the system was adjusted to 6-7 by dilute ammonia water and dilute hydrochloric acid, fully stirred at room temperature for 30 minutes, and the stirred product was left to stand at room temperature for 6 hours. After standing still, put it into a refrigerator to freeze at -20°C, and then use a lyophilizer to lyophilize to obtain phytic acid-crosslinked polyallylamine hydrochloride gel-coated hollow SnO2 nanometer microspheres.

[0036] It can be seen from the charge-discharge cycle test that the hollow SnO coated with 90% phytic acid cross-linked polyallylamine hydrochloride gel 2 exhibited a capacity of 368mAh g at the 100th cycle -1 . This shows that 90wt% phytic acid-crosslinked PAH gel is less effective in improving the circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com