Method for eutectic soldering of large substrate on tube shell

A technology of eutectic welding and large substrates, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid devices, etc., can solve the problems of long production time period, difficult processing, damage to large substrates and shells, etc., and achieve the goal of manufacturing Simple and cheap, improve the penetration rate, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

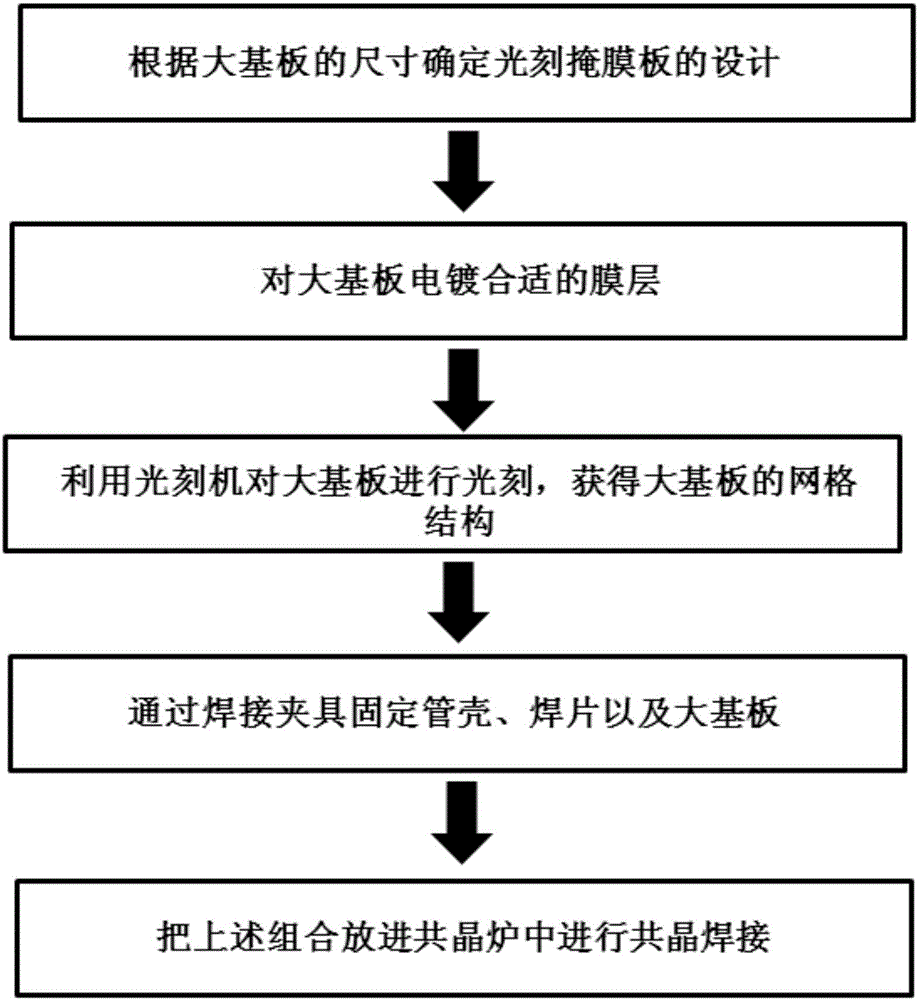

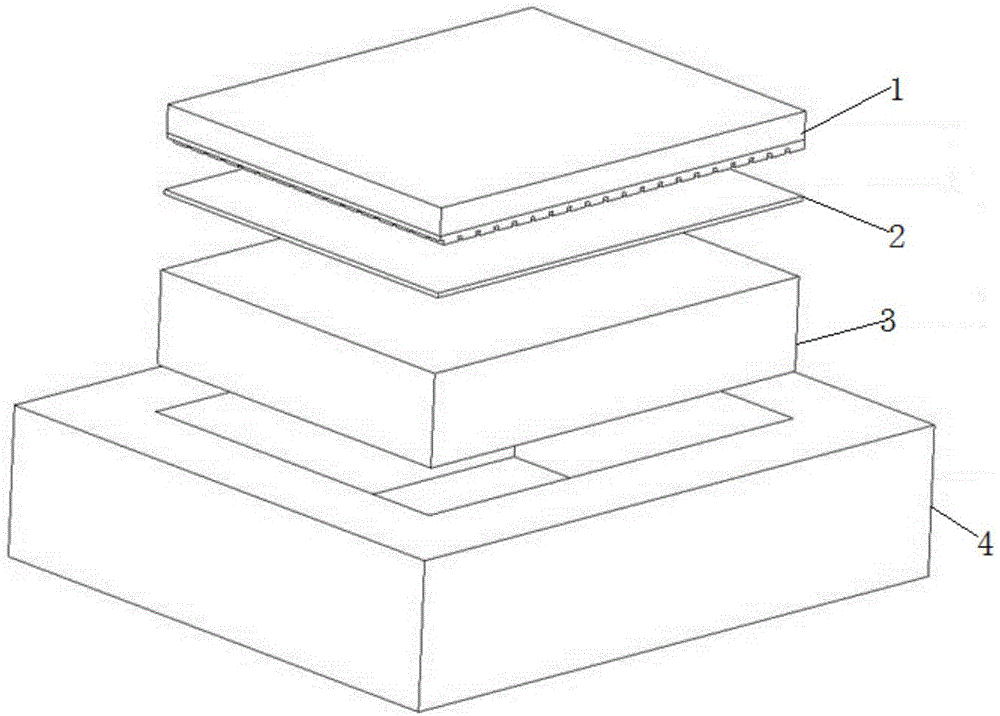

[0030] like Figure 1-4 As shown, a method of eutectically welding a large substrate on a tube shell is carried out in the following order:

[0031] Step 1: Select a suitable photolithography mask according to the specifications of the large substrate; the size of the substrate is generally above 3cm×3cm.

[0032] Step 2: electroplating a film layer on one side of the large substrate;

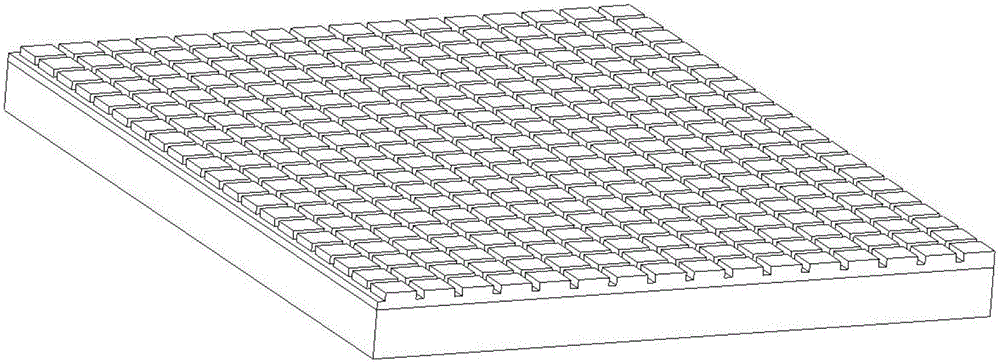

[0033] Step 3: Use a photolithography machine and a photolithography mask to perform photolithography processing on the film layer of the large substrate to obtain a grid-shaped large substrate 1, where the grid is a grid array of 1.9mm×1.9mm, and the grid is The spacing is 0.1mm, the grid is the opaque part in the photolithography mask, and the spacing is the transparent part;

[0034] Step 4: Use the welding jig 4 to fix the shell 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com