A New Laminated Wound Film Capacitor

A film capacitor, laminated technology, applied in the field of new laminated winding film capacitors, can solve the problems that cannot fully meet the requirements of miniaturization, and achieve the effect of improving self-healing performance, low loss, and good self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

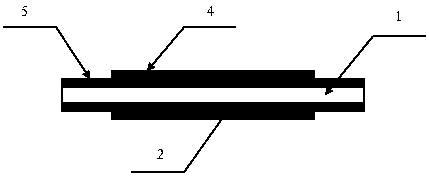

[0017] Such as figure 1 and figure 2 As shown, the technical solution to achieve the above object is a novel laminated winding film capacitor, a novel laminated winding film capacitor, including an insulating dielectric layer 1, a metal plating layer 2 and an insulating varnish layer 4, the The insulating medium layer 1 is paved with a metal plating layer 2 on both sides, and one side of the left or right side of the insulating medium layer 1 is provided with a margin 3 without the metal plating layer 2, and the margins on both sides of the insulating medium layer 1 are 3 are arranged on different sides of the left or right respectively, the margin 3 is covered with an insulating varnish layer 4, the outside of the metal plating layer 2 is covered with an insulating varnish layer 4, and one side of the left or right side of the metal plating layer 2 The painted margin 5 is not covered with the insulating paint layer 4, the painted margin 5 and the margin 3 are respectively s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com