Actuating device, manufacturing method therefor, and underwater acoustic transducer

A technology of actuating devices and actuators, which is applied in the direction of sound-emitting devices, instruments, and water resources assessment, and can solve problems such as fracture, easy damage, and low bending and torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

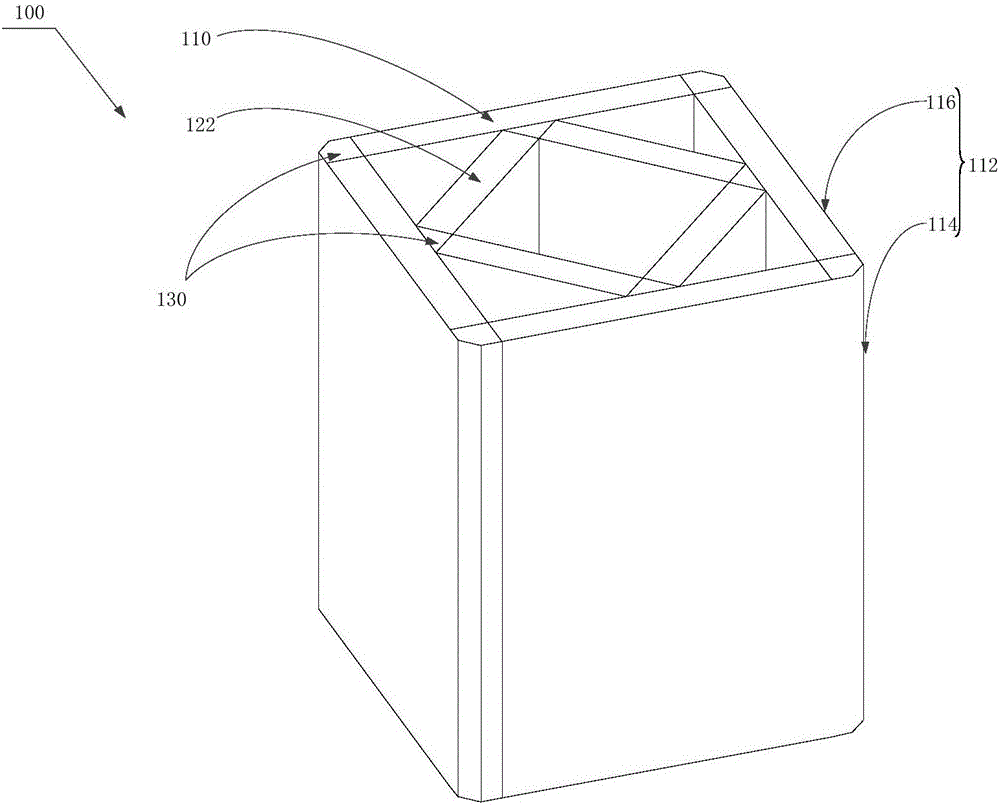

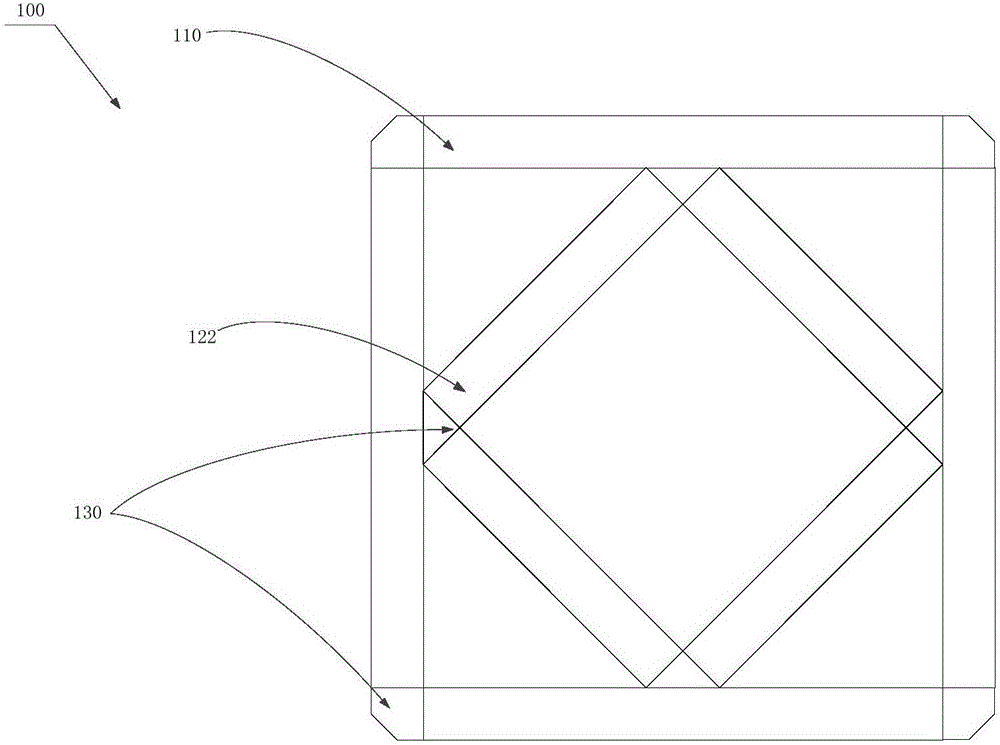

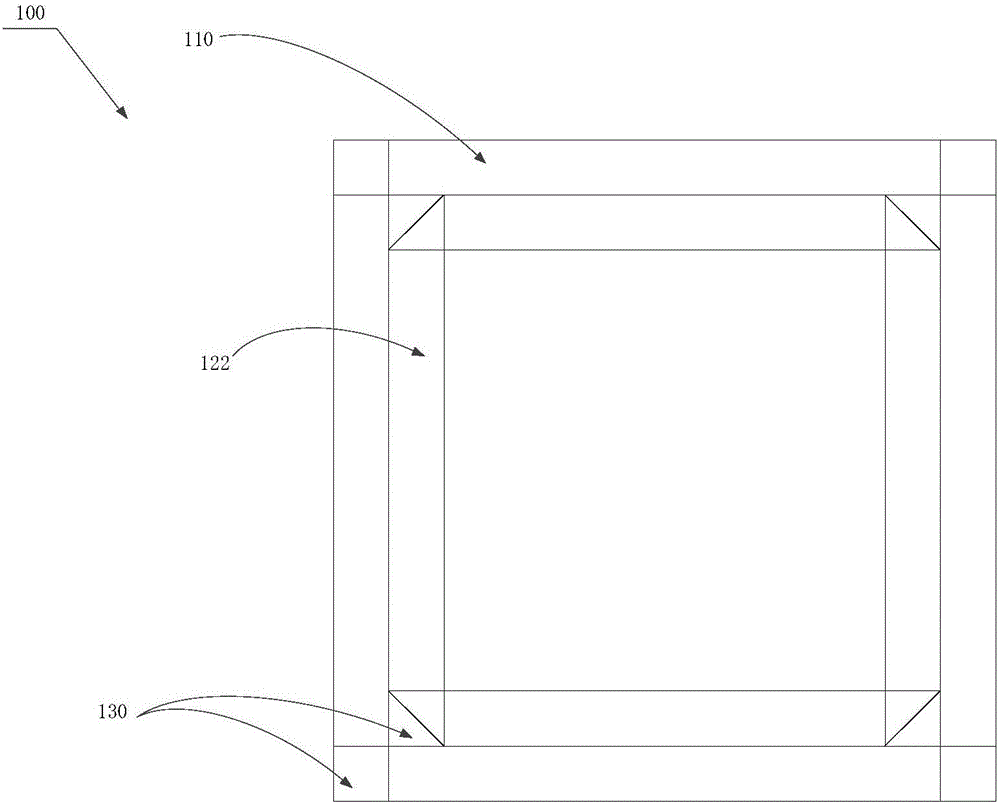

[0037] Please refer to Figure 1 to Figure 4 , Shows a schematic structural diagram of an actuation device 100 provided by an embodiment of the present invention. The actuating device 100 includes a first actuator 110 and a support 120, and the support 120 is disposed in the first actuator 110.

[0038] The first actuator 110 includes a plurality of first single crystals 112, and the single crystals are rectangular piezoelectric single crystals in a transverse mode, preferably lead-based relaxor ferroelectric single crystals with ultra-high transverse strain. Including [011] direction polarization, [100] direction drive d 32 Single chip or [011] direction polarization, [0-11] direction driven d 31 Single wafer. The constituent material of the single chip may be a relaxor ferroelectric single crystal, for example: lead zinc niobate-lead titanate (PZN-PT), lead magnesium niobate-lead titanate (PMN-PT), lead magnesium niobate -Lead zirconate titanate (PMN-PZT), lead niobate indium-...

no. 2 example

[0049] Please refer to Figure 5 to Figure 7 It is shown that this embodiment provides an actuating device 100. The actuating device 100 includes a first actuator 110 and a support 120, and the support 120 is disposed in the first actuator 110. The difference from the above-mentioned embodiment is that the supporting member 120 is a single-chip pair 126, and the single-chip pair 126 is disposed in the first actuator 110 for stably supporting the first actuator. 器110.

[0050] The single-chip pair 126 includes two second single-chips 123 arranged oppositely, and the second single-chip 123 is the same as the single-chip provided in the above-mentioned embodiment. Preferably, the two second single-chips of the single-chip pair 126 123 parallel settings. The relative positional relationship between the at least one single-chip pair 126 and the first actuator 110 can be various, including but not limited to the three mentioned in the following embodiments.

[0051] See Figure 5 The r...

no. 3 example

[0057] See Figure 8 , Shows a schematic structural diagram of a hydroacoustic transducer 200 provided in this embodiment. The hydroacoustic transducer 200 includes a front cover 210, a rear mass 220, and the actuation device 100 provided in the foregoing embodiment. The actuation device 100 includes a first connection end and a second connection end that are axially arranged, the front cover 210 is connected to the first connection end of the actuation device 100, and the second connection end of the actuation device 100 is connected to the The rear mass 220 is connected.

[0058] The underwater acoustic transducer 200 refers to the use of the piezoelectric effect of crystals (quartz or potassium sodium tartrate), piezoelectric ceramics (barium titanate and lead zirconate titanate, etc.) or the magnetostrictive effect of iron-nickel alloys. work. The so-called piezoelectric effect is to cut the piezoelectric body into slices in a certain direction, and apply pressure on the pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com