Overhead line fault positioning monitoring device

A fault location and monitoring device technology, which is applied in the direction of fault location and fault detection according to the conductor type, can solve problems such as unsatisfactory magnetic flux circuits, complicated operation conditions, and difficult troubleshooting, and achieve the goal of overcoming unsatisfactory magnetic flux circuits and overcoming Safety cannot be guaranteed, and the effect of high fault capture accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the technical content of the present invention, the technical solution thereof will be further elaborated below in conjunction with the accompanying drawings and instructions for use.

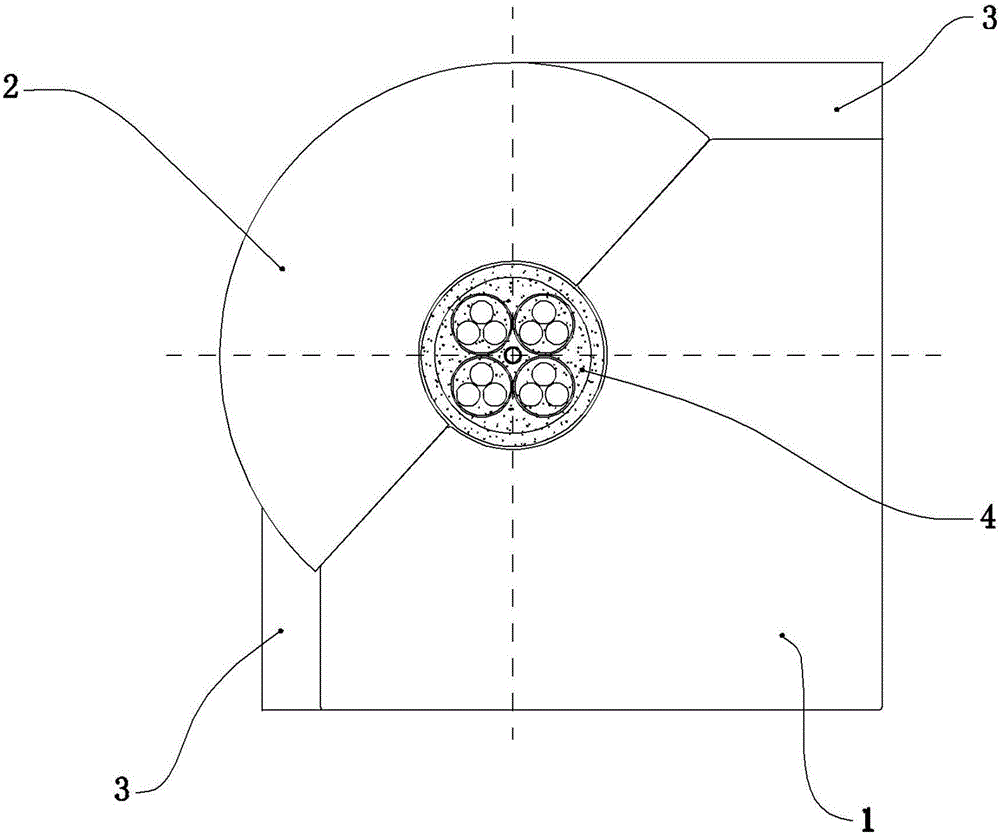

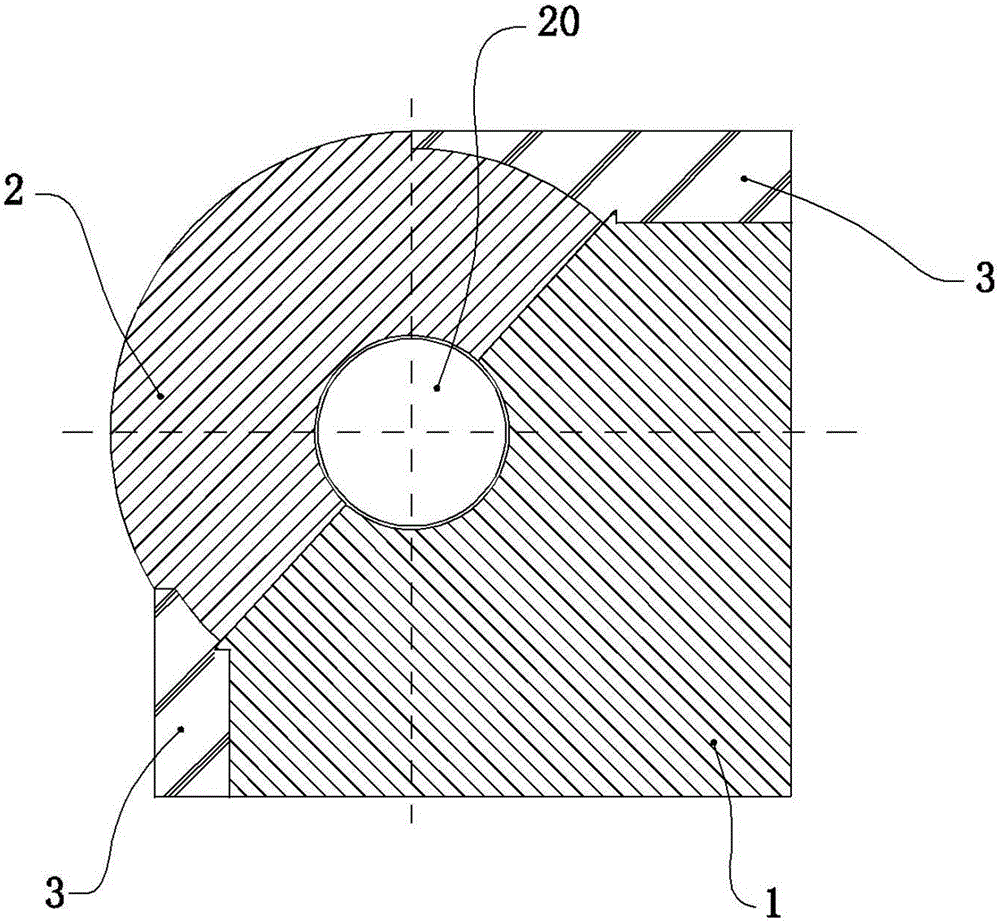

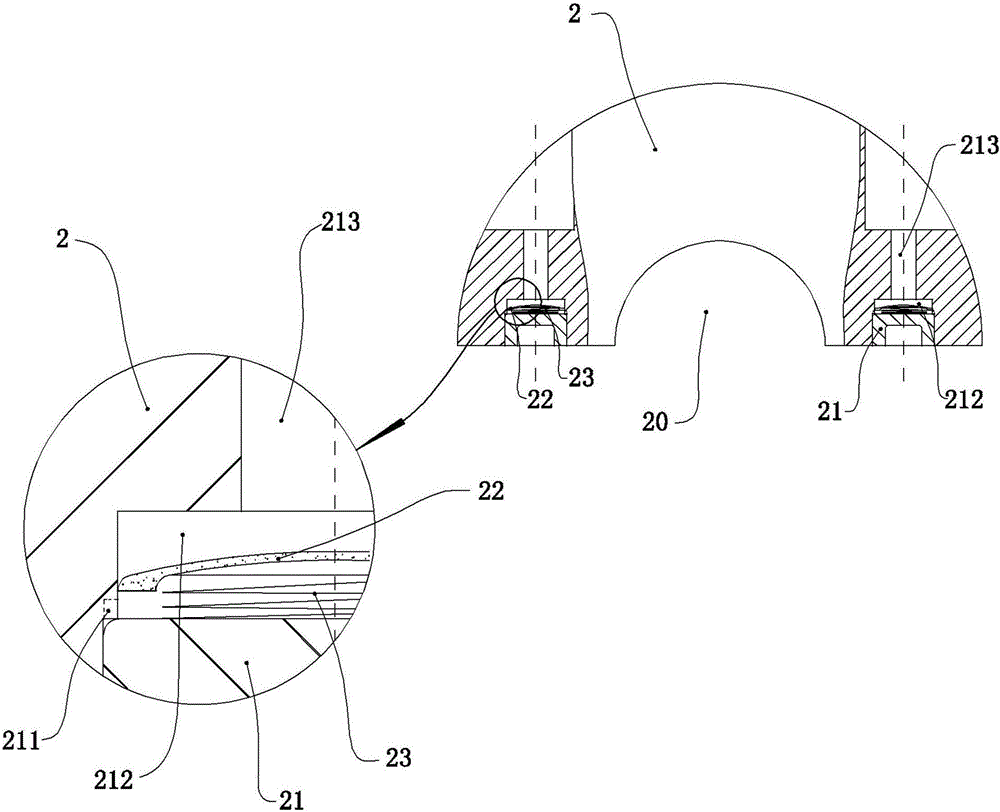

[0026] Such asfigure 1 , figure 2 The overhead line fault location monitoring device shown includes a base 1 and a fault detection module installed on the base 1 for detecting faults in distribution lines. The upper end of the vertical surface on the left side of the base is an inclined plane (even if the upper left corner of the base 1 forms an inclined plane), and the angle of inclination is 45 degrees relative to the horizontal plane. Corresponding cable grooves 20 for embedding cables are provided on the flat surface of the inclined surface and the end of the flip cover corresponding to the inclined surface of the base. As shown in the figure, the cable groove 20 on the flip cover 2 extends along the central axis. When the base 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com