Process for preparing mesoporous graphene and field effect transistor biosensor based on mesoporous graphene

A field-effect transistor and mesoporous graphene technology, applied in the field of biosensors, can solve the problems of random layer stacking structure, uneven layer number, complex manufacturing process, etc., to improve sensitivity, high current switching ratio, and reduce manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] (1) Preparation of graphene film 11 by chemical vapor deposition method, as attached figure 1 , Transfer the graphene film 11 to Si / SiO 2 On the substrate 21, Si / SiO is obtained 2 / Graphene 22, clean, N 2 Blow dry for use;

[0037] (2) Disperse PMMA nanospheres 23 with a particle size of 8-80nm in a mixed solvent of 5-10mL deionized water / absolute ethanol (volume ratio 1:1), and slowly drop the PMMA nanosphere 23 dispersion into In the 0.5-5wt% surfactant SDS solution, PMMA nanospheres 23 are assembled at the gas / liquid interface to form a single-layer nanosphere film, Si / SiO 2 / Graphene 22 is inserted obliquely below the liquid surface, and the single-layer PMMA nanosphere 23 film is transferred to the graphene surface;

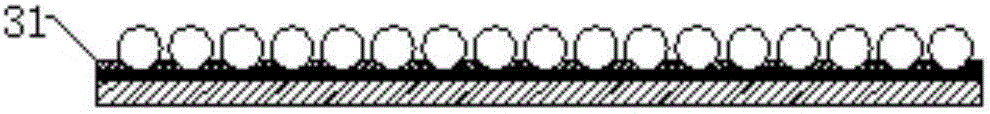

[0038] (3) The Si / SiO obtained in (2) 2 / Graphene / PMMA nanospheres, bake at 120-150℃ for 10-30min to make PMMA nanospheres 23 closely adhere to the surface of graphene 22, as attached figure 2 ; Then, a 10-100nm metal film 31, such as a metal Al film, is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com