Platinum-tin oxide nanofiber membrane sensitive to methane

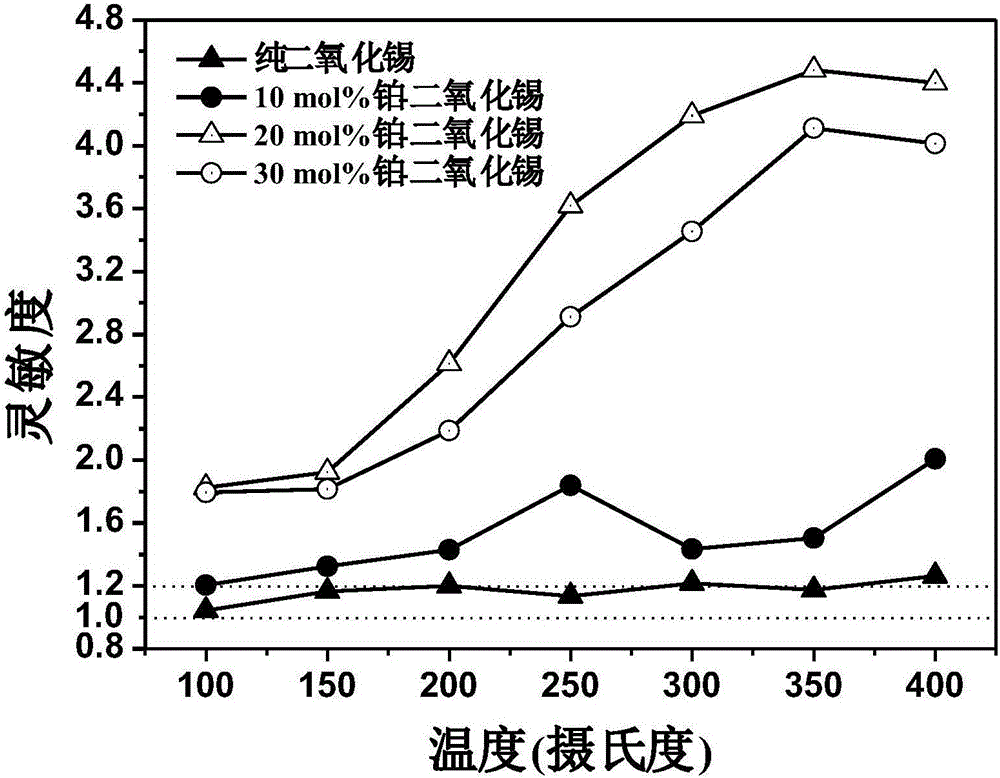

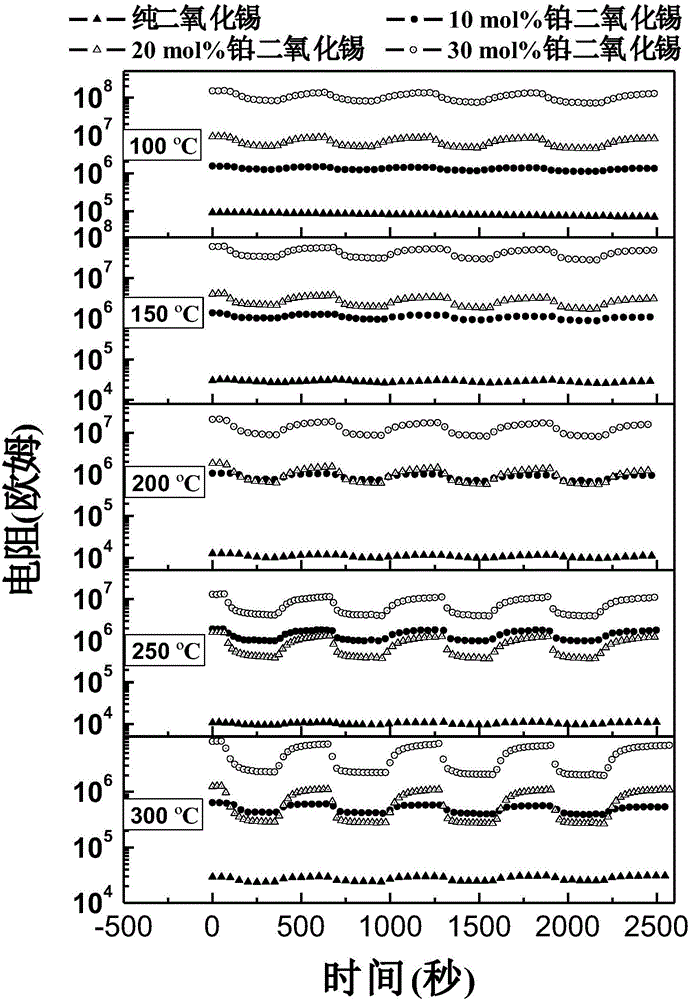

A nanofiber film and tin dioxide technology, applied in the field of gas sensor, can solve the problems of methane sensor gas sensor performance without smooth and continuous methane response, complex preparation method, low application value, etc., to achieve good application value and prospect, preparation The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

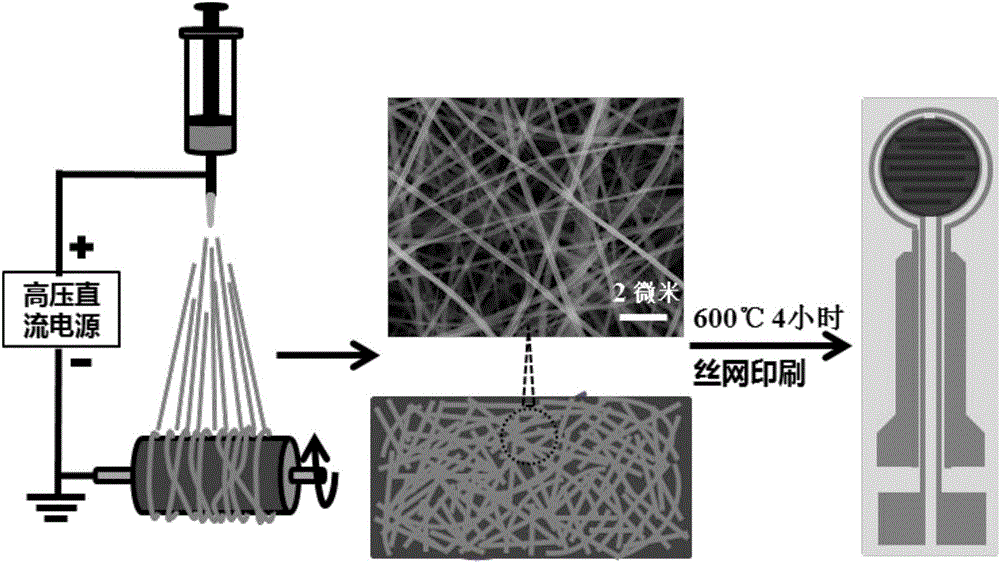

Method used

Image

Examples

Embodiment 1

[0022] Example 1, 0.4 gram of tin protochloride dihydrate and an appropriate amount of chloroplatinic acid are added to the mixed solution of 4.42 gram of dimethylformamide and 4.42 gram of absolute ethanol (0mol%, 10mol%, 20mol%, 30mol% % four doping concentrations), the mixed solution was magnetically stirred for 30 minutes, then 0.8 g of polyvinylpyrrolidone was added thereto, and then stirred for 12 hours to obtain a clear and transparent electrospinning precursor solution. Use a 5 ml syringe to measure a certain amount of electrospinning precursor solution for spinning. Set the bolus injection speed to 0.137 mm / min, the syringe uses a 21-gauge needle, and the distance between the needle and the receiver is about 19 cm. The forward voltage of the DC high-voltage power supply is 20 kV, the negative voltage is 2 kV, and the spinning time is 3 hours. The obtained nanofibers were dried in a drying oven at 40° C. for 24 hours, and then placed in a tube furnace for calcination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com