Method and device for testing pressure resistance of optical fiber coating

A technology of optical fiber coating and testing method, which is applied to measuring device, using stable tension/pressure to test material strength, strength characteristics, etc. Different, easily affected by test conditions, etc., to achieve the effect of favoring stability and repeatability, improving stability and repeatability, and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

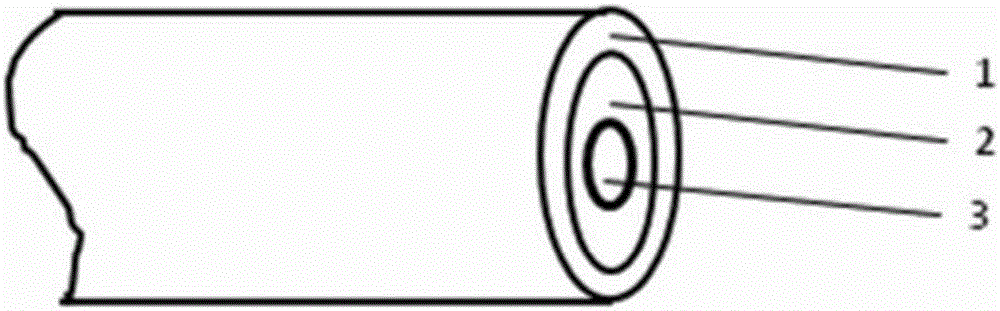

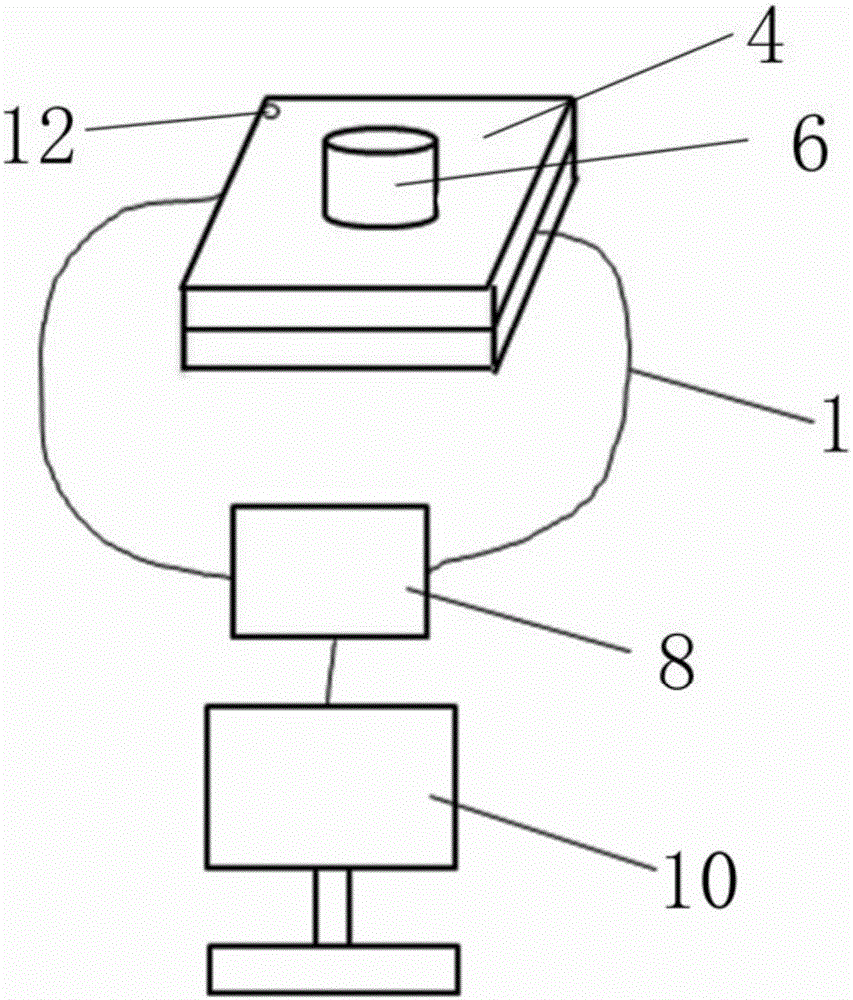

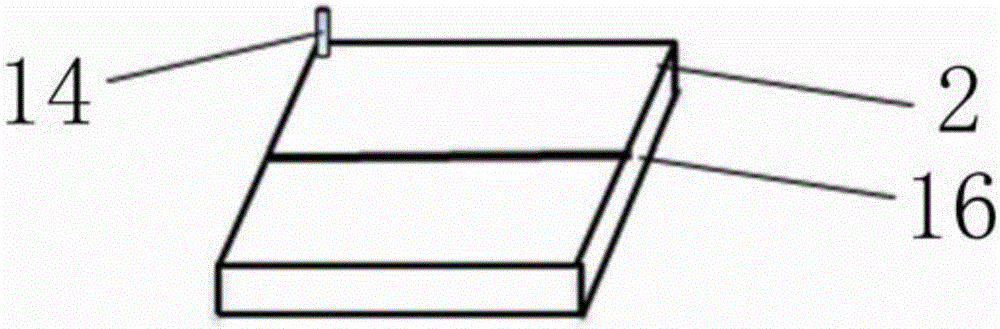

[0040] like figure 2 , 3 As shown, a device for measuring the pressure resistance performance of optical fiber coating is disclosed in this embodiment, which includes a test substrate 2, a pressure plate 4, a counterweight 6, an optical power meter 8 and a computer 10, wherein the test substrate 2 and the pressure plate 4 are all used Stainless steel plate, in the early stage, the stainless steel plate is processed into a rectangular parallelepiped structure with a length of 25-30mm, a width of 15-20mm, and a height of 20-30mm to form a test substrate 2 and a pressure plate 4, both of which are in contact with the surface of the optical fiber 1 to be tested ( That is, the surface roughness of the test surface) is 0.05-0.1um, and the test reference line 16 is made at the center of the width of the test substrate 2 to ensure that the optical fiber 1 is placed along the test reference line 16 for each test. During the measurement, the press plate 4 is fitted and arranged direct...

Embodiment 2

[0042] The present embodiment provides a test method for testing the pressure resistance performance of the optical fiber coating based on the above-mentioned measuring device, which includes the following steps:

[0043] (1) Take an optical fiber and intercept three sections of equal length, with a length of 3-5m, to form three sections of optical fiber to be tested, namely L1, L2, and L3;

[0044] (2) Under the test conditions that the temperature is 20°C-28°C and the humidity is RH40%-60%, the test substrate 2 is placed on a stable working platform, and the middle part of the optical fiber L1 to be tested in the Pass through the surface of the substrate 2, first fix a free end of the optical fiber L1 on the working platform with adhesive tape, straighten the optical fiber L1 so that the optical fiber L1 coincides with the test reference line 16 on the test substrate 2, and then tape the optical fiber L1 The other free end is fixed on the working platform. The pressure plate a...

Embodiment 3

[0051] Steps (2) to (4) of this embodiment are the same as those in Embodiment 1,

[0052] (5) Take two counterweights 6 with a weight of 50-500 g and place them on the center of the pressure plate 4, and measure the optical power loss of the optical fiber L1 after placing the two counterweights according to the method of step (4), denoted as X2;

[0053] (6) The difference between X2 and X0 is the optical power loss under the pressure of the two counterweights of the optical fiber L1, denoted as Δ1;

[0054] (7) Follow the steps (2) to (6) to test the optical power loss of the optical fiber L2 to be tested and the optical fiber L3 to be tested under the pressure of two counterweights, which are respectively recorded as Δ1, Δ2 and Δ3, and Δ1, Δ2 and Δ3 are taken the average of the three As the optical power loss of the entire fiber under test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com