Method of recovering and preparing cuprous oxide by taking waste copper-tungsten alloy as raw material

A technology of copper-tungsten alloy and cuprous oxide is applied in the field of recycling and preparing cuprous oxide, which can solve problems such as increasing production cost, and achieve the effects of easy operation, mild reaction conditions, high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

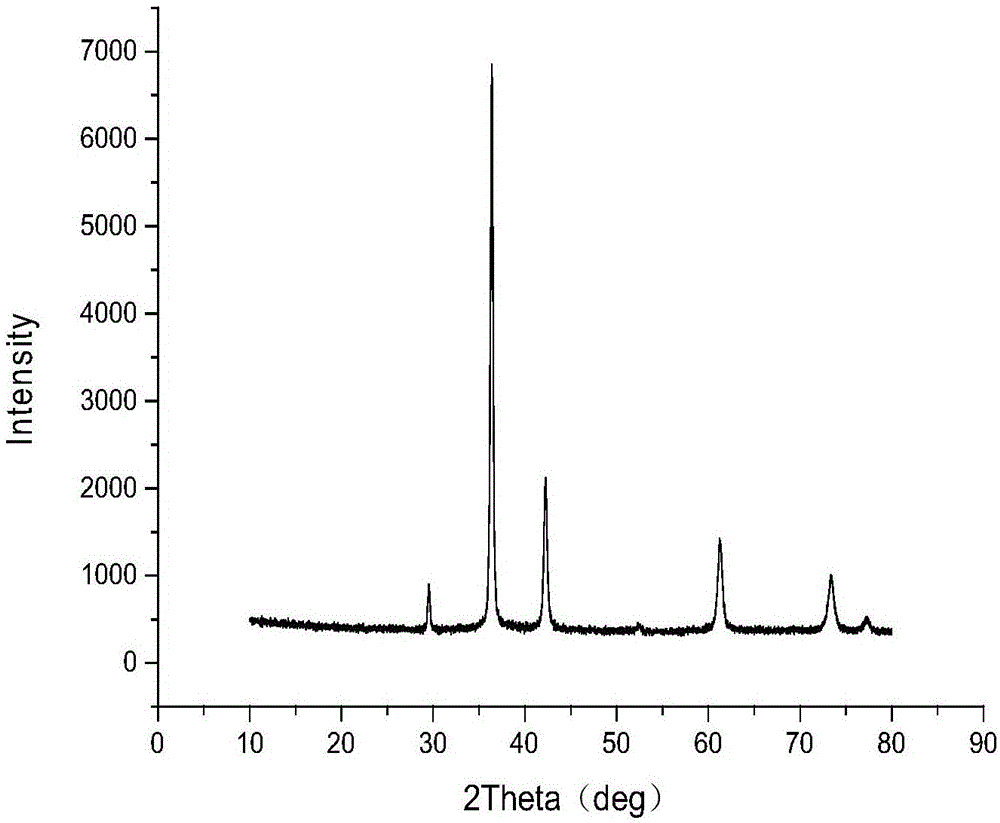

Image

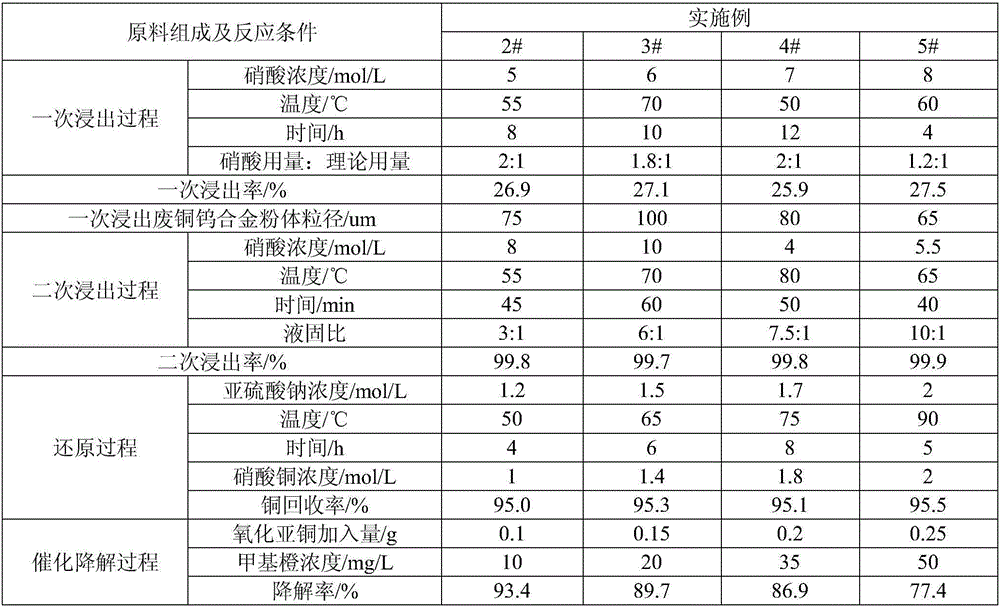

Examples

Embodiment 1

[0021] (1) Take 10g of scrap copper-tungsten alloy, and use nitric acid with a concentration of 4mol / L to leach the copper in the scrap copper-tungsten alloy once. The nitric acid leaching temperature is 40°C, the leaching time is 6h, and the amount of nitric acid is 1 times the theoretical amount. Copper nitrate stock solution, the primary leaching rate is 26.1%;

[0022] (2) pulverizing the scrap copper-tungsten alloy remaining in step (1) into micron-sized powder, the powder particle size is at 50um;

[0023] (3) Take 2g of the waste copper tungsten powder prepared in step (2), the nitric acid concentration is 6mol / L, the nitric acid leaching temperature is 40°C, the nitric acid leaching time is 30min, and the liquid-solid ratio is 1:1 to obtain a copper nitrate solution, The secondary leaching rate reaches 99.8%;

[0024] (4) The process of sodium sulfite reduction to prepare cuprous oxide, the concentration of sodium sulfite is 1mol / L, the concentration of copper nitrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com