Oil-permeable water-blocking type propping agent and preparation method thereof

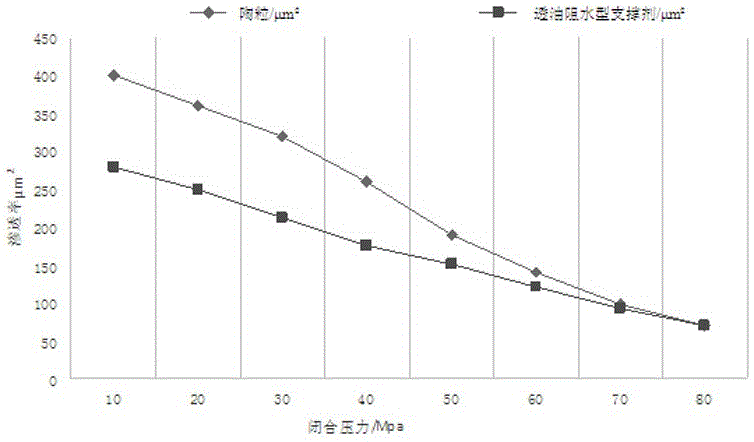

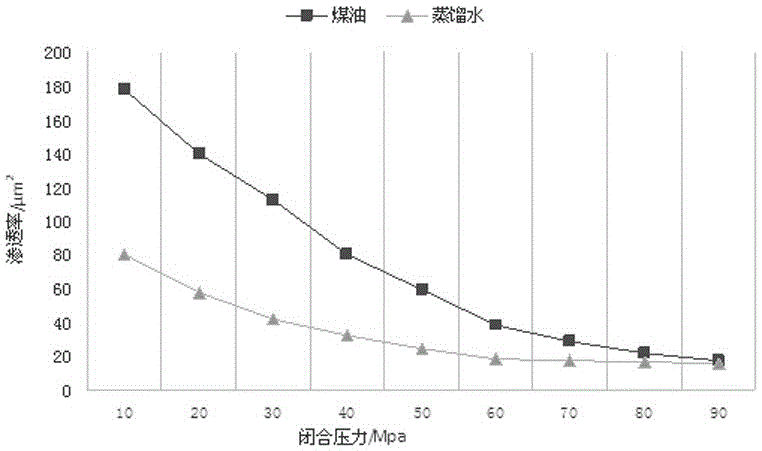

A proppant and water-blocking technology, which is applied in chemical instruments and methods, earth drilling, production fluids, etc., can solve the problems of increasing oil costs and reducing oil benefits, so as to improve production and grade, good lipophilicity and hydrophobicity, The effect of increasing oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing an oil-permeable and water-repelling proppant, comprising the following steps:

[0028] (1) Add 0.5g of Aquolin® 161 and 30g of nano-titanium dioxide to 500g of polyurethane solution, ultrasonically disperse for 30 minutes to obtain a suspension with nanoparticles dispersed; wherein, the polyurethane solution is made of Adwel® 1650 dissolved in ethyl acetate Obtained in the polyurethane solution, the mass percent of polyurethane is 5%;

[0029] (2) Weigh 1kg of quartz sand and put it into the resin sand mixer, heat it to 180°C, add 0.5g of aminopropyltriethoxysilane (KH550) under the condition of heat preservation and stirring, and add 60g of bisphenol A epoxy after 20s Resin, then add 3g dimethyl phthalate and 4g carbon black in turn, continue to stir for 30s, add 5g triethylenetetramine, there are signs of dispersion when stirring for 10min, add 1g calcium stearate, disperse for 10s, discharge and cool to room temperature and sieved to obtain t...

Embodiment 2

[0041] A method for preparing an oil-permeable and water-repelling proppant, comprising the following steps:

[0042](1) Add 0.6g of Aquolin® 161 and 30g of nano-polystyrene to 500g of polyurethane solution, ultrasonically disperse for 30 minutes to obtain a suspension with nanoparticles dispersed; wherein, the polyurethane solution is made of Adwel® 1645 dissolved in acetic acid Obtain in ethyl ester, the mass percent of polyurethane in the polyurethane solution is 5%;

[0043] (2) Weigh 1kg of ceramsite and put it into the resin sand mixer, heat it to 180°C, add 0.5g of methacryloxypropyltrimethoxysilane (KH570) under the condition of heat preservation and stirring, and add 60g of bismuth after 20s Phenol A epoxy resin, then add 3g dibutyl phthalate, 4g carbon black in turn, continue stirring for 30s, add 5g diethylenetriamine, there are signs of dispersion when stirring for 10min, add 1g zinc stearate, disperse for 10s, Discharge, cool to room temperature, and sieve to obt...

Embodiment 3

[0047] A method for preparing an oil-permeable and water-repelling proppant, comprising the following steps:

[0048] (1) Add 0.7g of Aquolin® 161 and 40g of nano-titanium dioxide to 500g of polyurethane solution, ultrasonically disperse for 30 minutes to obtain a suspension with dispersed nanoparticles; wherein, the polyurethane solution is made of Adwel® 1650 dissolved in ethyl acetate Obtained in the polyurethane solution, the mass percent of polyurethane is 5%;

[0049] (2) Weigh 1kg of quartz sand and put it into the resin sand mixer, heat it to 180°C, add 1g of aminopropyltriethoxysilane (KH550) under the condition of heat preservation and stirring, and add 40g of bisphenol A epoxy resin after 20s , then add 5g dimethyl phthalate and 6g alcohol-soluble black dye in turn, continue to stir for 30s, add 4g triethylenetetramine, there are signs of dispersion when stirring for 10min, add 3g calcium stearate, disperse for 10s, discharge, Cool to room temperature and sieve to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com