Polymer hybrid proton exchange membrane modified by metal organic framework structures and preparation method of membrane

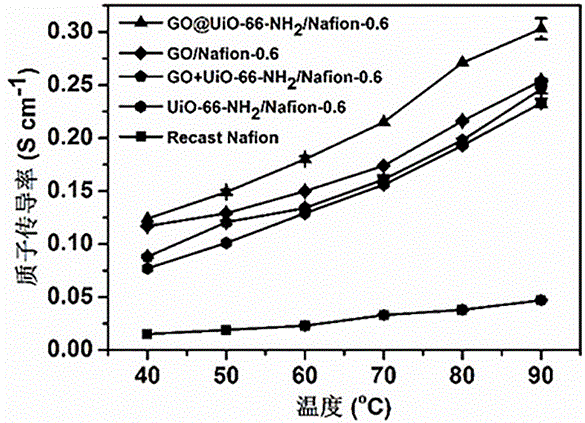

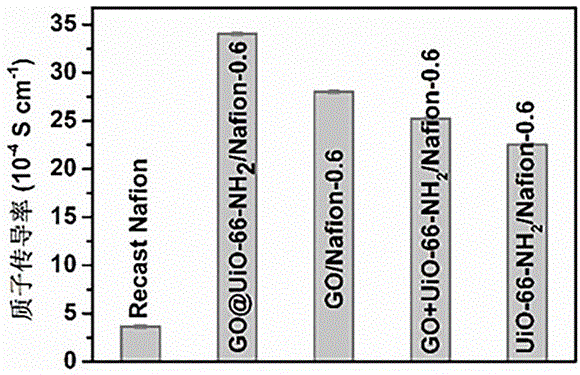

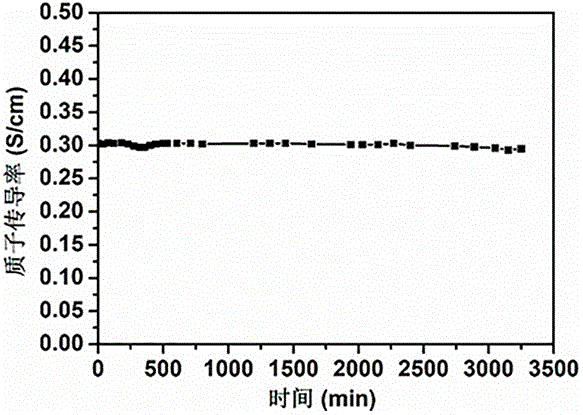

A metal-organic framework and proton exchange membrane technology, which is applied in electrochemical generators, climate sustainability, and final product manufacturing, can solve problems such as unsatisfactory proton conductivity, achieve excellent proton conductivity, strong water retention capacity, Effect of low fuel permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Weigh 0.13 g 2-aminoterephthalic acid and 0.17 g ZrCl respectively 4 , add it to the mixture of 0.8 mL HCOOH and 8 mL N,N-dimethylformamide (DMF), and ultrasonically disperse it into a uniform UiO-66-NH 2 The precursor solution was transferred to a 25 mL polytetrafluoroethylene liner, covered with a lid and placed in a reaction kettle to seal tightly, and then placed in a constant temperature oven at 120 °C for 24 h, and the reaction product was centrifuged Separated, first washed with fresh DMF solvent, and then with fresh CH 3 Soak in OH solvent for 3 days, replace with fresh CH twice a day 3 OH solvent, the soaked product was placed in an oven at 50 °C for 6 h, and a partially cross-linked amino-functionalized metal-organic framework (UiO-66-NH 2 ).

[0031] 2. Weigh 100 mg of GO into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse it into a uniform GO solution, add 50 mg of dopamine hydrochloride to the GO solution, and place it in an ice-wate...

Embodiment 2

[0036] 1. Weigh 0.26 g 2-aminoterephthalic acid and 0.17 g ZrCl respectively 4 , add it to the mixture of 0.8 mL HCOOH and 8 mL DMF, and ultrasonically disperse it into a uniform UiO-66-NH 2 The precursor solution was transferred to a 25 mL polytetrafluoroethylene liner, the lid was closed and placed in a reaction kettle to seal tightly, and then placed in a constant temperature oven at 120 °C for 24 h, and the reaction product was centrifuged Separated, first washed with fresh DMF solvent, and then with fresh CH 3 Soak in OH solvent for 3 days, replace with fresh CH twice a day 3 OH solvent, the soaked product was placed in an oven at 50 °C for 6 h, and a partially cross-linked amino-functionalized metal-organic framework (UiO-66-NH 2 ).

[0037] 2. Weigh 100 mg of GO into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse it into a uniform GO solution, add 50 mg of dopamine hydrochloride to the GO solution, and place it in an ice-water bath for ultrasonicati...

Embodiment 3

[0043] 1. Weigh 0.52 g 2-aminoterephthalic acid and 0.17 g ZrCl respectively 4 , add it to the mixture of 0.8 mL HCOOH and 8 mL DMF, and ultrasonically disperse it into a uniform UiO-66-NH 2The precursor solution was transferred to a 25 mL polytetrafluoroethylene liner, the lid was closed and placed in a reaction kettle to seal tightly, and then placed in a constant temperature oven at 120 °C for 24 h, and the reaction product was centrifuged Separated, first washed with fresh DMF solvent, and then with fresh CH 3 Soak in OH solvent for 3 days, replace with fresh CH twice a day 3 OH solvent, the soaked product was placed in an oven at 50 °C for 6 h, and a partially cross-linked amino-functionalized metal-organic framework (UiO-66-NH 2 ).

[0044] 2. Weigh 100 mg of GO into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse it into a uniform GO solution, add 50 mg of dopamine hydrochloride to the GO solution, and place it in an ice-water bath for ultrasonicatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com