Method for preparing phthalic acid through liquid phase catalytic oxidation of xylene

A technology for phthalic acid and xylene liquid, which is applied in the field of liquid phase oxidation of xylene to prepare phthalic acid, can solve the problems that three kinds of xylene cannot share oxidation, different catalyst complexing abilities, and fluctuating catalyst concentration, etc. The effect of combined deactivation, small fluctuation range of catalyst concentration, and small amount of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A 2L continuous bubble column reactor was used, and the composition of the mixed solution was 60% dimethyl phthalate and 40% o-xylene. Wherein, the mass fraction of the catalyst is 0.012% cobalt isooctanoate, and the mass fraction of the additive 2,2-bipyridine is 0.02%. The liquid feed rate is 15g / min, the air feed rate is 10L / min, the reaction temperature is 170°C, the pressure is 1.1MPa, the residence time is 1h, the conversion rate of o-xylene is 60.2%, and the total selectivity of phthalic acid is 96.5%, tail gas oxygen concentration 3.2%, tail gas CO 2 Concentration 1.2%.

Embodiment 2~6

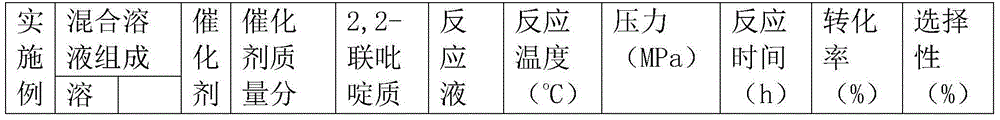

[0020] Embodiment 2~6: repeat the reaction process of embodiment 1, difference is to use different solvent catalyst and reaction condition. The specific raw material reaction conditions and results of each embodiment are listed in Table 1.

[0021] Table 1, embodiment 2~6 specific reaction conditions

[0022]

[0023]

Embodiment 7

[0025] A 1L batch stirred tank reactor was used, and the composition of the mixed solution was 65% diethyl terephthalate and 35% p-xylene. Wherein, the catalyst is cobalt naphthenate with a mass fraction of 0.01%, and the mass fraction of 2,2-bipyrimidine is 0.02%. The mixed liquid was 600g, the reaction temperature was 160°C, the pressure was 1.5MPa, the reaction time was 4h, the conversion rate of p-xylene was 70.2%, and the total selectivity of terephthalic acid was 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com