Igniting packaging powder head based on self-propagating reaction and packaging method thereof

A technology of igniting powder and encapsulation method, which is applied in fuzes, explosives, offensive equipment, etc., can solve the problems that self-propagating powder cannot be tightly sealed, restricts the industrialization of self-propagating technology, and is rarely made into products. To achieve the effect of ensuring the success rate of ignition, taking into account safety and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

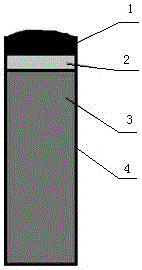

Image

Examples

Embodiment 1

[0030] In this embodiment, "copper-clad steel exothermic flux" is used as the packaging target, and 500 g of exothermic flux is used as a container with a thin-walled plastic tube, and the mouth of the tube is opened.

[0031] The Al powder of 15 parts by weight, the CuO powder of 65 parts by weight, the Fe powder of 10 parts by weight and the sawdust of 10 parts by weight are mixed uniformly, obtain powder A; 70 parts by weight of potassium permanganate, 20 parts by weight of charcoal and 10 parts by weight of One part of sulfur is mixed uniformly to obtain powder B; to powder A, add 4 parts by weight of polytetrafluoroethylene suspension with a mass concentration of 60%, mix uniformly, and after being muddy, press molding again to obtain a powder tip; to powder B Add 4 parts by weight of an acetone solution of celluloid with a mass concentration of 55%, mix evenly, and then press to form it, and embed the ignition device at the same time to obtain a packaged drug tip; press t...

Embodiment 2

[0034] In this embodiment, "rail exothermic flux" is used as the packaging target, and 1000 g of exothermic flux is used as a container with a thin-walled plastic bottle, and the mouth of the bottle is opened.

[0035] The Al powder of 18 parts by weight, the CuO powder of 70 parts by weight, the Fe powder of 6 parts by weight and the sawdust of 6 parts by weight are mixed uniformly, obtain powder A; 73 parts by weight of potassium permanganate, 22 parts by weight of charcoal and 5 parts by weight of 5 parts of sulfur are mixed uniformly to obtain powder B; to powder A, add 5 parts by weight of polytetrafluoroethylene suspension with a mass concentration of 65%, mix uniformly, and after being muddy, press molding again to obtain a powder tip; to powder B Add 5 parts by weight of an acetone solution of celluloid with a mass concentration of 60%, mix evenly, and then press to form it, and embed the ignition device at the same time to obtain a packaged drug tip; press the ignition...

Embodiment 3

[0038] The Al powder of 13 parts by weight, the CuO powder of 58 parts by weight, the Fe powder of 6 parts by weight and the sawdust of 6 parts by weight are mixed uniformly, obtain powder A; With 65 parts by weight of potassium permanganate, 15 parts by weight of charcoal and 5 parts by weight One part of sulfur is mixed uniformly to obtain powder B; to powder A, add 3 parts by weight of polytetrafluoroethylene suspension with a mass concentration of 50%, mix uniformly, and after being muddy, press molding again to obtain a powder tip; to powder B Add 3 parts by weight of an acetone solution of celluloid with a mass concentration of 45%, mix evenly, and then press to form it, and embed the ignition device at the same time to obtain a packaged drug tip; press the ignition tip and the packaged drug tip in turn The opening of the container containing the self-spreading medicinal powder is pressed tightly, and the opening is sealed at the same time to avoid stratification by vibra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com