Factory-like cultivation medium for needle mushrooms and cultivation method

A technology of cultivation substrate and cultivation method, which is applied to the industrial cultivation substrate and cultivation field of Flammulina velutipes, can solve problems such as unstable cultivation period, high pressure on enterprises, shortened cultivation period, etc., and achieves increased antibacterial and antiviral ability, good disease resistance and Insect resistance, appearance and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

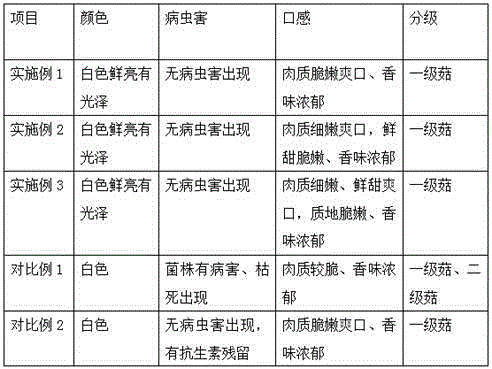

Examples

Embodiment 1

[0052] A factory cultivation substrate of Flammulina velutipes is made from the following raw materials in parts by weight: the raw materials are composed of 25 parts of bran, 72 parts of sawdust, 3 parts of light calcium, 22 parts of antibiotic scum and 8 parts of sweet potato vines.

[0053] Bran is fresh, non-mildew, non-rancid fine bran, water content ≤ 15%, 6.2 ≤ pH ≤ 6.8; light calcium: water content ≤ 9%, 8.5 ≤ pH ≤ 9.5; antibiotic residues are aminoglycosides Fungus residue;

[0054] Antibiotic slag pretreatment: add 10%wt calcium oxide to the antibiotic slag, stir evenly, then adjust the water content to 55%, seal and compact for 6 hours, cool down to room temperature, inject ozone to maintain the concentration of 1.5g / m3, Stir for 2 hours, wash and filter with water, adjust the water content to 65%, add proteolytic enzyme (proteolytic enzyme is a mixture of serine protease, aspartic acid protease, thiol protease, metalloprotease), the concentration is 1.0g / m3, 28 Fe...

Embodiment 2

[0086] A factory cultivation method of Flammulina velutipes, comprising the following steps:

[0087] A factory cultivation substrate of Flammulina velutipes, made of the following raw materials in parts by weight: 20 parts of bran, 70 parts of sawdust, 3 parts of light calcium, 20 parts of antibiotic scum and 8 parts of sweet potato vines;

[0088] Bran is fresh, non-mildew, non-rancid fine bran, water content ≤ 15%, 6.2 ≤ pH ≤ 6.8; light calcium: water content ≤ 9%, 8.5 ≤ pH ≤ 9.5; antibiotic residue is β-lactam fungus-like residue;

[0089] Antibiotic scum pretreatment: with embodiment 1.

[0090] A factory cultivation method of Flammulina velutipes, the steps are the same as in Example 1.

Embodiment 3

[0092] A factory cultivation substrate of Flammulina velutipes is made from the following raw materials in parts by weight: 25 parts of bran, 75 parts of sawdust, 4 parts of light calcium, 25 parts of antibiotic scum and 10 parts of sweet potato vine;

[0093] Bran is fresh, non-mildew, non-rancid fine bran, water content ≤ 15%, 6.2 ≤ pH ≤ 6.8; light calcium: water content ≤ 9%, 8.5 ≤ pH ≤ 9.5; antibiotic residue is macrolide fungus-like residue;

[0094] Antibiotic scum pretreatment: with embodiment 1.

[0095] A factory cultivation method of Flammulina velutipes, the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com