Domestic garbage undersize and sludge mixed carbonization treatment system

A technology for domestic waste and carbonization treatment, applied in gas treatment, pyrolysis treatment of sludge, chemical instruments and methods, etc. The effect of reducing carbonized ash powder and fast fiber carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

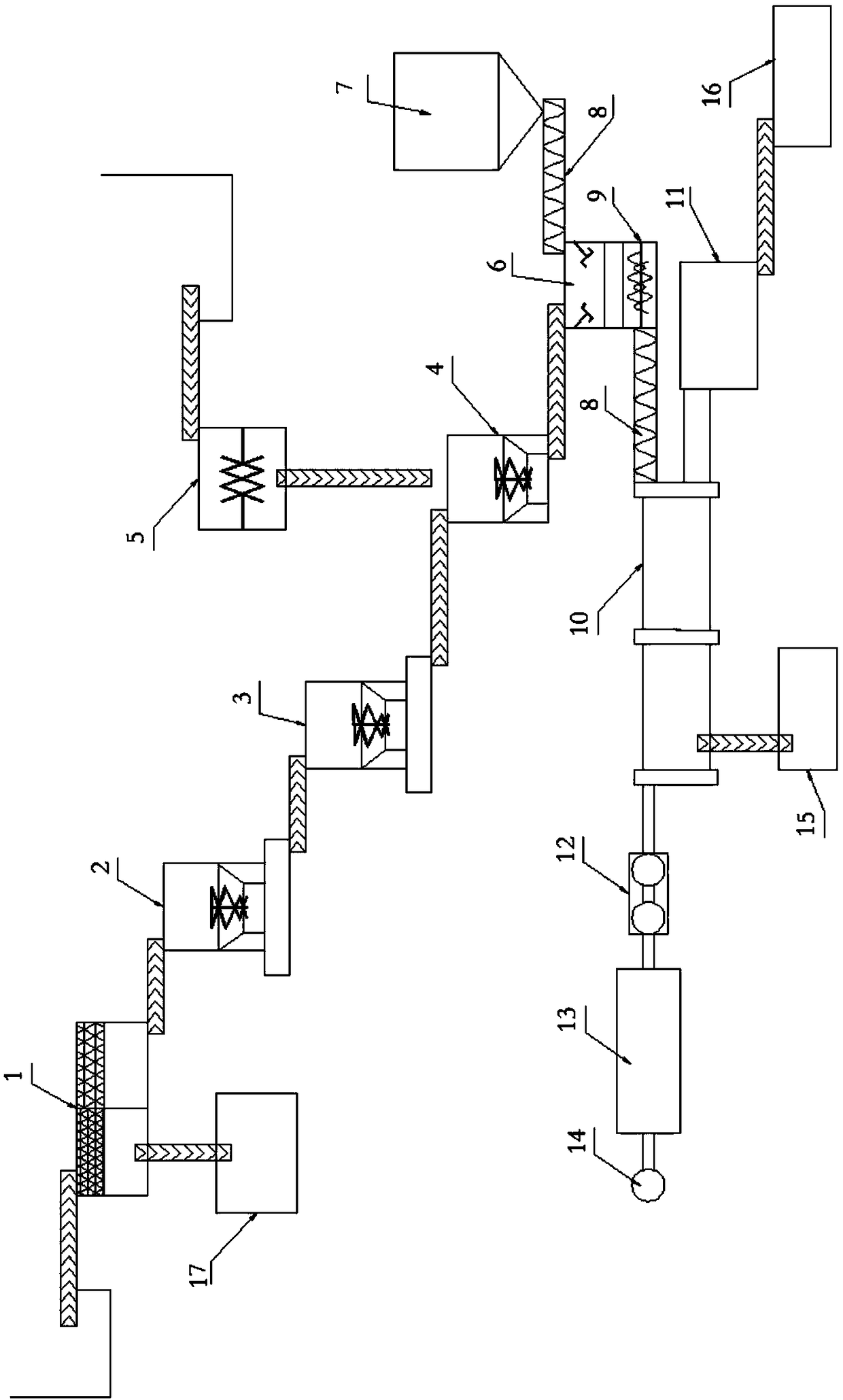

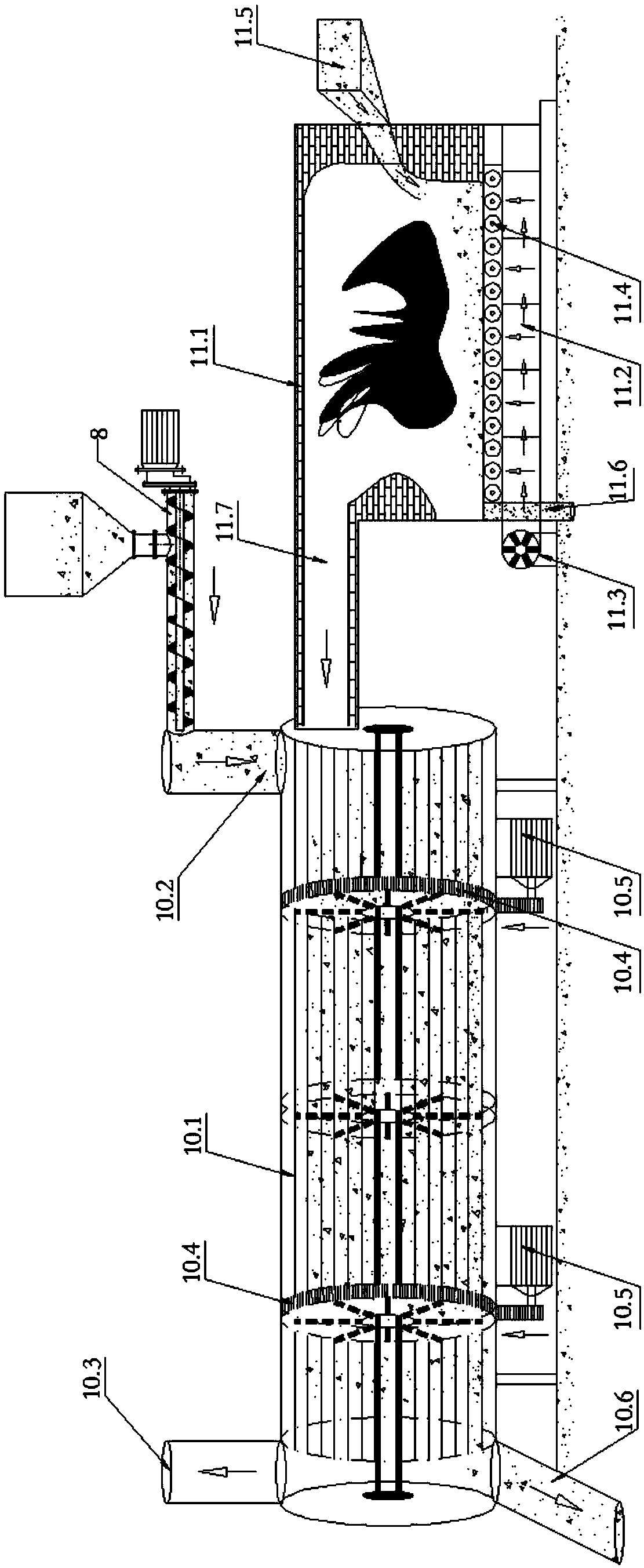

[0036] Such as figure 1 As shown, a mixed carbonization treatment system of domestic garbage undersize and sludge, including a fine garbage sorting mechanism 1, a primary shear crusher 2, an intermediate shear crusher 3, a tertiary fine crusher 4, Straw shearing crusher 5, agitating mixer 6 and carbonization furnace 10, the garbage fine sorting mechanism 1, primary shearing crusher 2, and intermediate shearing crusher 3 are connected in sequence through a belt conveyor , the intermediate shearing crusher 3 is connected to a feeding port of the three-stage fine crusher 4 through a belt conveyor, and the straw shearing crusher 5 is connected to the other of the three-stage fine crusher 4 through a belt conveyor. Feed port, the discharge port of the three-stage fine crusher 4 is connected to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com