Preparation method of SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of increased production cost and narrow synthesis range, and achieve improved utilization rate, huge industrial application prospects, The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

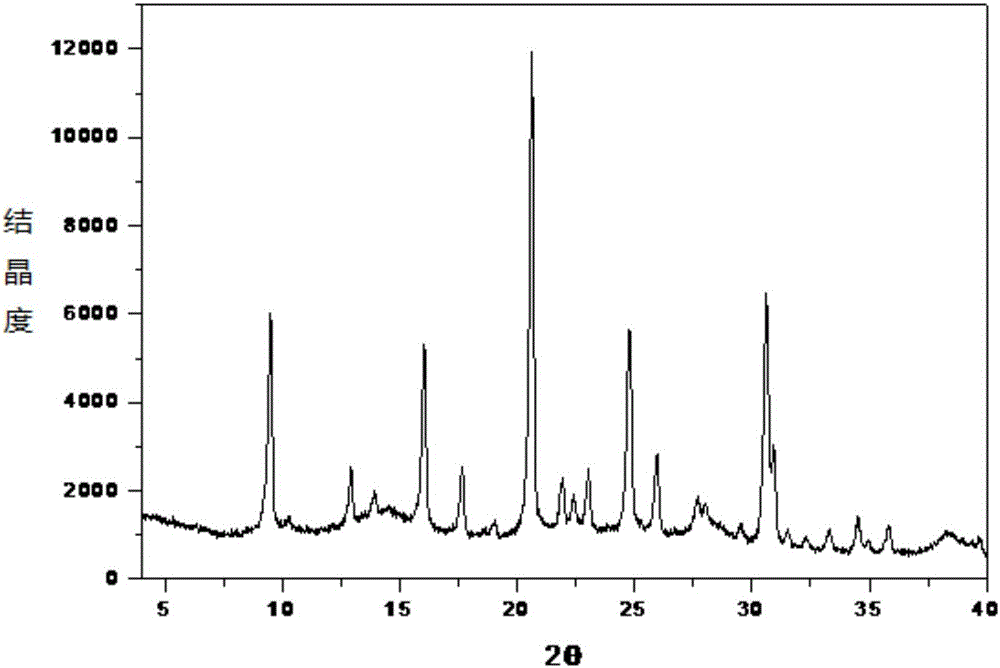

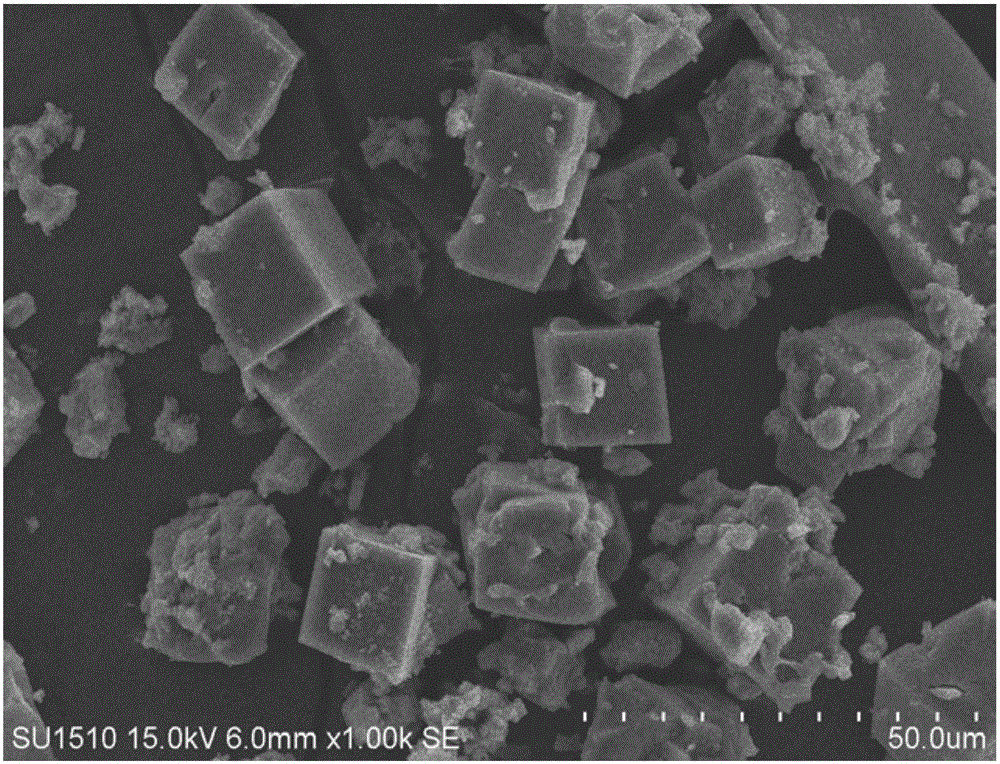

[0027] The invention discloses a preparation method of SAPO-34 molecular sieve. The molecular sieve is synthesized by solid-phase grinding, which includes the following steps: firstly, the reaction raw materials silicon source, aluminum source, template agent R1 and water are ground for 10-20 minutes, and then put into Carry out the crystallization reaction in the reaction kettle; after the crystallization is completed, cool at room temperature, wash with deionized water until neutral, and dry in the air at 80°C to obtain the original molecular sieve powder; roast the original molecular sieve powder in the air at 600°C for 4 hours, Obtain final product; The addition amount of each reaction raw material should make the molar ratio of each composition when crystallization reaction is: Al 2 o 3 : SiO 2 :H 2 O: R1 is 0.5~1.5:0.4~1.0:1.2~3.6:1.0~2.0, wherein the templating agent R1 is selected from tetraethylenepentamine phosphate TEPA·H 3 PO 4 , Diethylene triamine phosphate D...

Embodiment 1

[0033] Example 1: Slowly drop 11.53 g of phosphoric acid into 3.89 g of tetraethylenepentamine, add 30 mL of ethanol, stir for 3 hours, and reflux the ethanol at 80° C. to obtain a light yellow solid. Then wash with ether and ethanol 3 to 4 times, and finally dry it.

Embodiment 2

[0034] Example 2: Slowly drop 11.53 g of phosphoric acid into 5.44 g of tetraethylenepentamine, add 30 mL of ethanol, stir for 3 hours, and reflux the ethanol at 80° C. to obtain a light yellow solid. Then wash with ether and ethanol 3 to 4 times, and finally dry it.

[0035] Synthesis of Diethylenetriamine Phosphate DETA·H 3 PO 4 :

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com