System and method for treating used electronic product

An electronic product and waste technology, applied in the field of solid waste recycling, can solve the problems of high equipment requirements, high raw material cost, and high energy consumption, achieve clean and efficient resource treatment, reduce heating energy consumption, and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

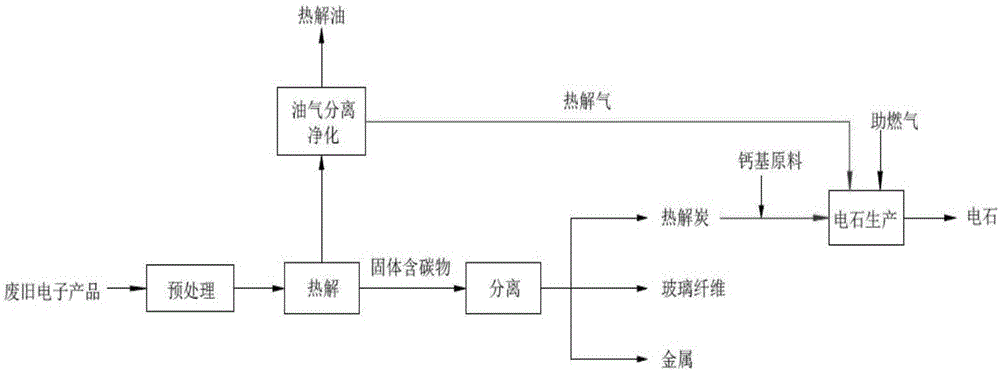

[0052] This embodiment proposes a system for processing waste electronic products, which includes a pretreatment unit, a pyrolysis unit, a separation unit, a mixing unit, an oil and gas separation and purification unit, and a calcium carbide production unit:

[0053] A Pretreatment: Disassemble and recycle the recyclable components of waste electronic products, coarsely crushing, and the crushing particle size is 100mm.

[0054] B pyrolysis: Evenly feed the crushed waste circuit board raw materials into the pyrolysis furnace for pyrolysis reaction. The pyrolysis temperature is 850°C and the pyrolysis time is 0.5h. After the pyrolysis reaction is complete, high-temperature oil gas and solid carbon are generated. The high-temperature oil and gas are collected and sent to the calcium carbide production unit through the oil and gas pipeline installed in the pyrolysis furnace, and the solid carbonaceous matter is discharged through the outlet.

[0055] C Separation: The solid carbo...

Embodiment 2

[0064] The present embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as follows:

[0065] A Pretreatment: Disassemble and recycle the recyclable components of waste electronic products, coarsely crush them, and the crushing particle size is 60mm.

[0066] B pyrolysis: Evenly feed the crushed waste circuit board raw materials into the pyrolysis furnace for pyrolysis reaction. The pyrolysis temperature is 650°C and the pyrolysis time is 1.5h. After the pyrolysis reaction is complete, high-temperature oil gas and solid carbon are generated. The high-temperature oil and gas are collected and sent to the calcium carbide production unit through the oil and gas pipeline installed in the pyrolysis furnace, and the solid carbonaceous matter is discharged through the outlet.

[0067] C Separation: The solid carbonaceous matter from the pyrolysis unit is separated into metal, glass fiber and pyrolytic carbon through f...

Embodiment 3

[0076] The present embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as follows:

[0077] A Pretreatment: Disassemble and recycle the recyclable components of waste electronic products, and coarsely crush them with a particle size of 40mm.

[0078] B pyrolysis: Evenly feed the crushed waste circuit board raw materials into the pyrolysis furnace for pyrolysis reaction. The pyrolysis temperature is 450°C, and the pyrolysis time is 3 hours. After the pyrolysis reaction is complete, high-temperature oil gas and solid carbon-containing substances are generated. , high-temperature oil and gas are collected and sent to the calcium carbide production unit through the oil and gas pipeline installed in the pyrolysis furnace, and the solid carbonaceous matter is discharged through the outlet.

[0079] C Separation: The solid carbonaceous matter from the pyrolysis unit is separated into metal, glass fiber and pyrolytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com