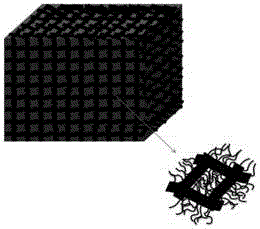

Preparation method of three-dimensional graphene/carbon nano tube composite material having isotropic high heat conduction and elasticity

An isotropic, carbon nanotube technology, applied in the field of preparing three-dimensional carbon materials with high thermal conductivity and compression resilience, can solve problems such as poor mechanical properties, poor bonding force, and unsatisfactory applications, and achieve the goal of improving thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 8ml of the graphene oxide aqueous dispersion into a 10ml hydrothermal reaction kettle, react at 150°C for 12h, and cool to room temperature to obtain a sponge. The samples were quickly frozen and then freeze-dried in a freeze dryer to obtain a three-dimensional graphene sponge.

[0026] 10ml of absolute ethanol, 10ml of xylene, and 4ml of ethylenediamine were prepared into a solution, and 0.48g of ferrocene was dissolved in the above solution to obtain a ferrocene solution with a concentration of 0.02g / ml.

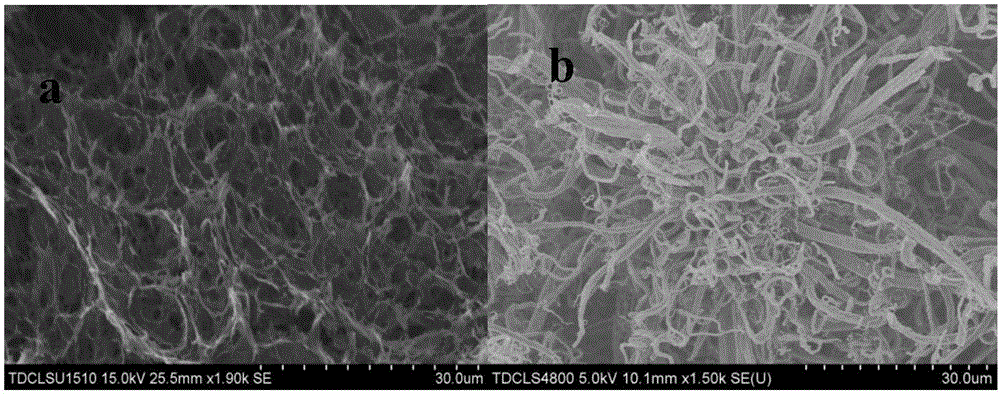

[0027] The prepared three-dimensional graphene sponge is placed in a tube furnace, and the temperature is raised to 700°C under the protection of argon. During the heating process, when the temperature is higher than 400°C, hydrogen is introduced. Under the mixed gas of hydrogen and argon, Inject the above-mentioned ferrocene solution, the injection speed is 10mL / h, the growth time is 30min, stop the injection of the ferrocene solution, and cool to room temperat...

Embodiment 2

[0029] Put 8ml of the graphene oxide aqueous dispersion into a 10ml hydrothermal reaction kettle, react at 180°C for 12h, and cool to room temperature to obtain a sponge. The samples were quickly frozen and then freeze-dried in a freeze dryer to obtain a three-dimensional graphene sponge.

[0030] 10ml of absolute ethanol, 5ml of xylene, and 2ml of ethylenediamine were prepared into a solution, and 0.34g of ferrocene was dissolved in the above solution to obtain a ferrocene solution with a mass fraction of 0.02g / ml.

[0031] Place the prepared three-dimensional graphene sponge in a tube furnace, and raise the temperature to 800°C under the protection of argon. During the heating process, when the temperature is higher than 400°C, hydrogen gas is introduced. Under the mixed gas of hydrogen and argon, inject For the above-mentioned ferrocene solution, the injection speed was 15 mL / h, and the growth time was 30 min. The injection of the ferrocene solution was stopped, and the sam...

Embodiment 3

[0033] Put 8ml of the graphene oxide aqueous dispersion into a 10ml hydrothermal reaction kettle, react at 180°C for 15h, and cool to room temperature to obtain a sponge. The samples were quickly frozen and then freeze-dried in a freeze dryer to obtain a three-dimensional graphene sponge.

[0034]10ml of absolute ethanol, 10ml of xylene, and 4ml of ethylenediamine were prepared into a solution, and 1.2g of ferrocene was dissolved in the above solution to obtain a ferrocene solution with a mass fraction of 0.05g / ml.

[0035] Place the prepared three-dimensional graphene sponge in a tube furnace, raise the temperature to 800°C under the protection of argon, and inject hydrogen when the temperature is higher than 400°C, and inject the above-mentioned ferrocene solution under the mixed gas of hydrogen and argon , the injection speed was 15mL / h, the growth time was 15min, the injection of ferrocene solution was stopped, and the sample was obtained by cooling to room temperature und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com