Ship keel structure and keel manufacturing method

A production method and keel technology, applied in the direction of hull keel, hull, ship construction, etc., can solve the problems of high difficulty of keel, high weight, complex equipment, etc., to improve the manufacturing accuracy and lead filling density, and ensure the installation accuracy , Improving the effect of straightness and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

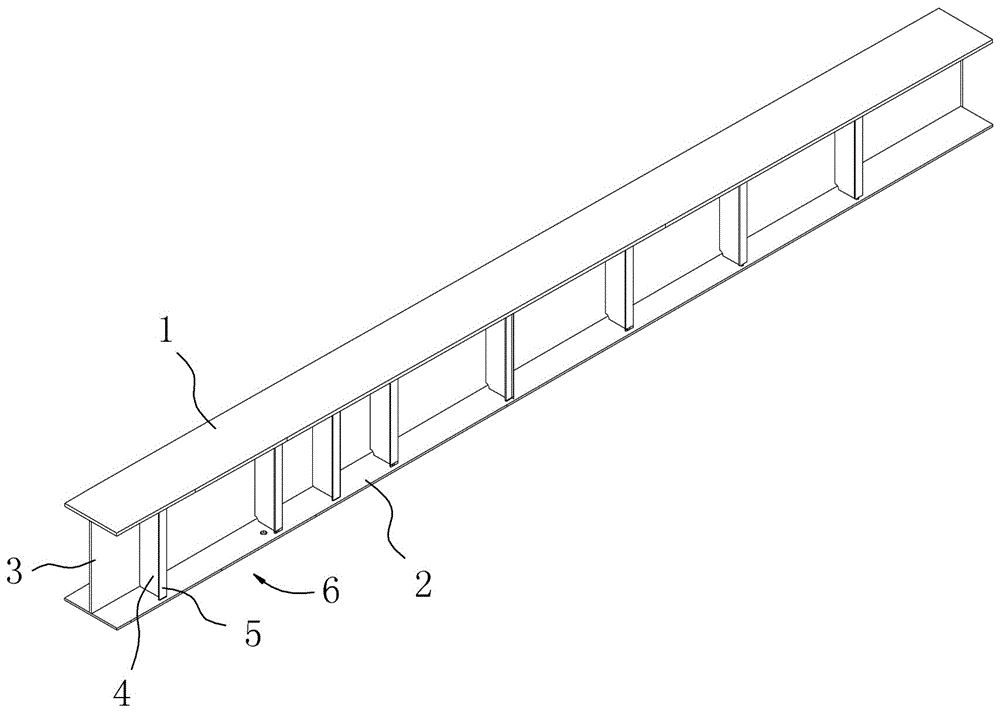

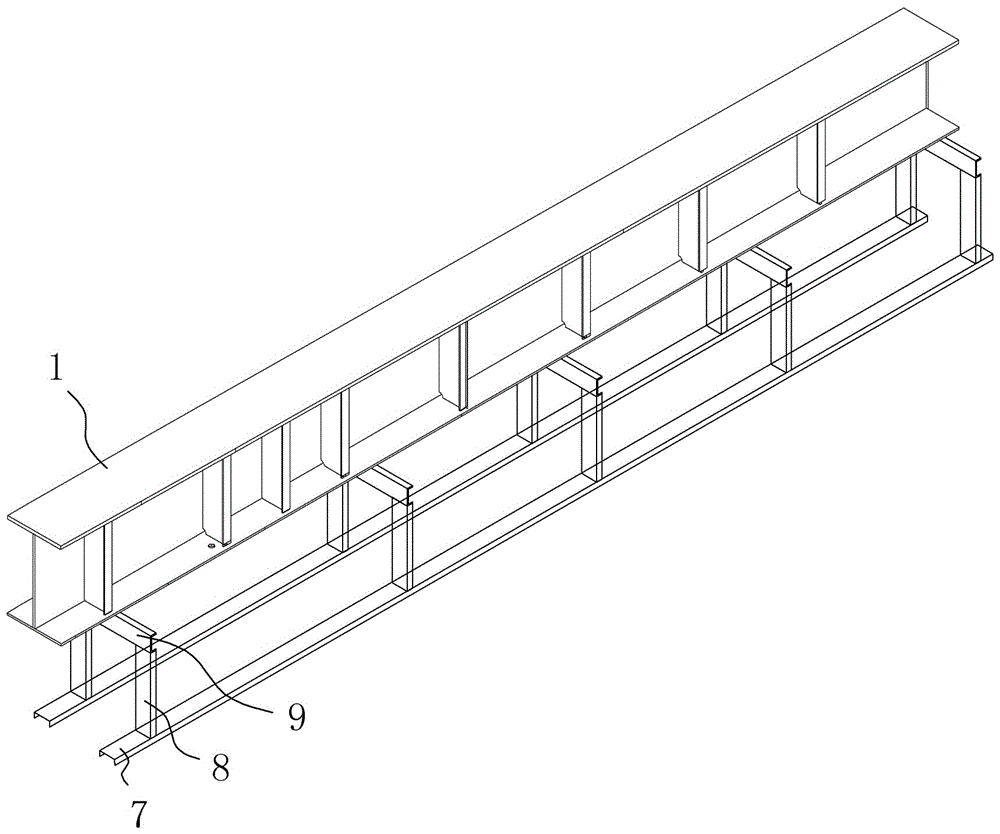

[0018] A ship keel structure, comprising a plurality of keel segments 10 connected end to end, each keel segment comprising an upper top plate 1, a bottom bottom plate 2, a middle partition 3 and a web 4, the top plate and the bottom plate are arranged horizontally, There are multiple partitions installed at intervals between the two, the partitions are vertically arranged and the plane of the board is perpendicular to the head and tail direction of the keel section, and the web is perpendicular to the top board and the partition; the top board, bottom board, partition and web surround A placement box 6 for placing lead weights is formed, and lead weights (not shown) are provided in all or part of the placement box of the keel segment. Through the keel of this structure and the method of making the keel, the manufacturing accuracy and lead filling density of the keel can be improved, and at the same time, the installation alignment accuracy of the front and rear segmental keels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com