Automatic double-rail film raising device

A film device and automatic technology, which is applied in the printing industry, can solve the problems of cart shaking, slow speed, laboriousness, etc., and achieve the effect of good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

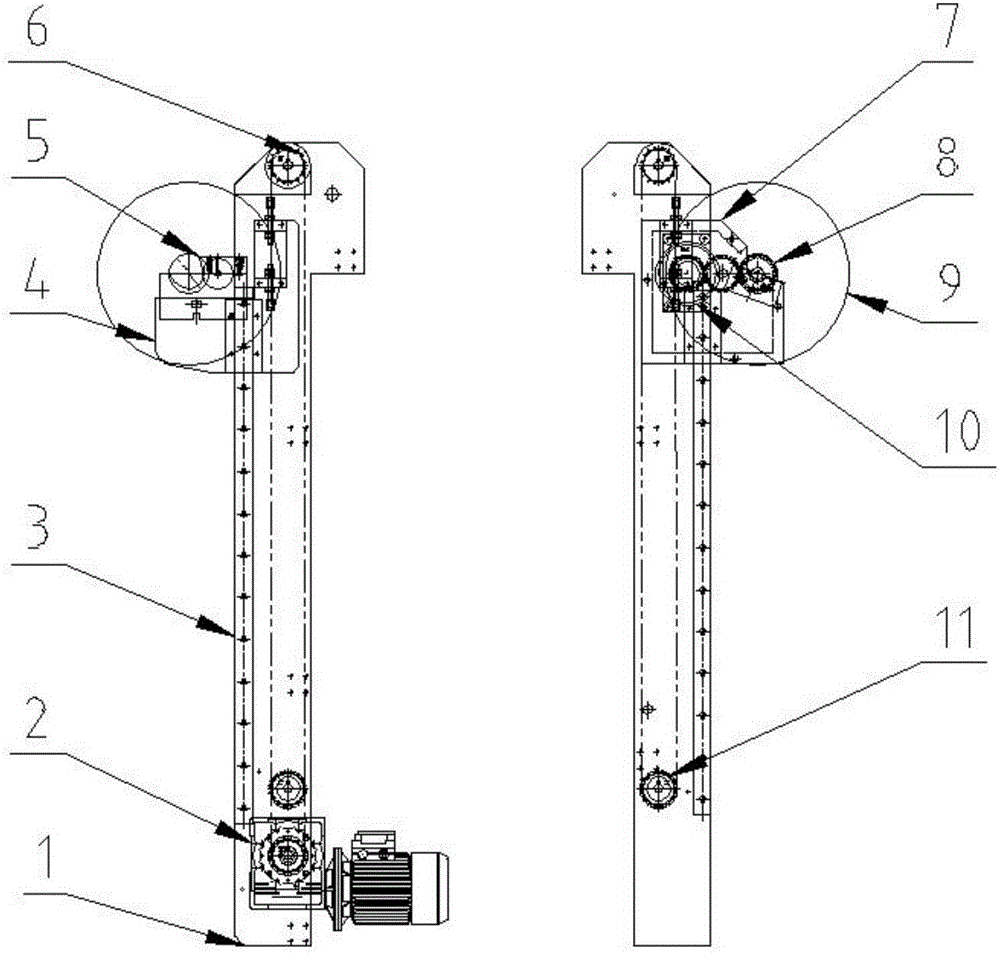

[0016] 1. Frame 2, motor 3, lifting guide rail 4, film release left support 5, film roll adjustment 6, top hanging wheel 7, film release right support 8, film roll transmission group 9, film roll rod 10, brake 11, lift Transmission 12. Electrical system

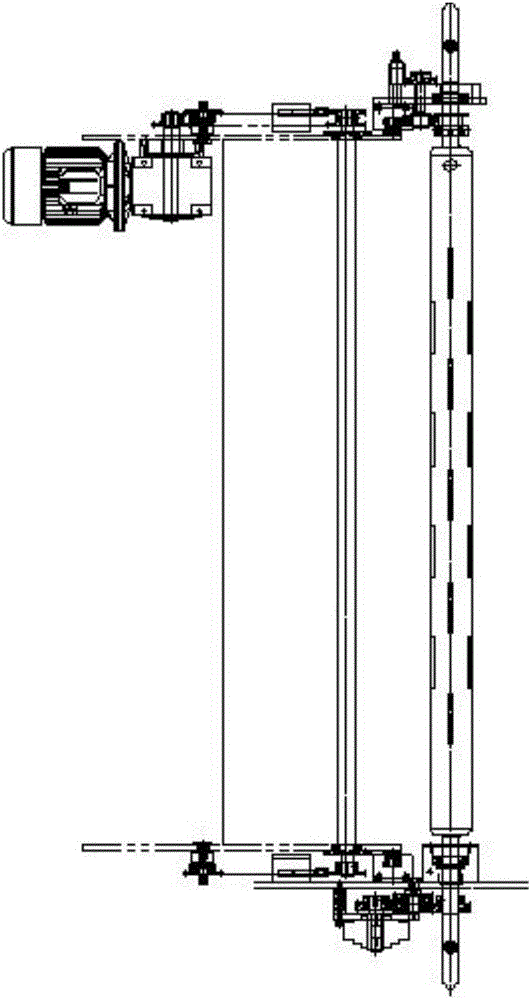

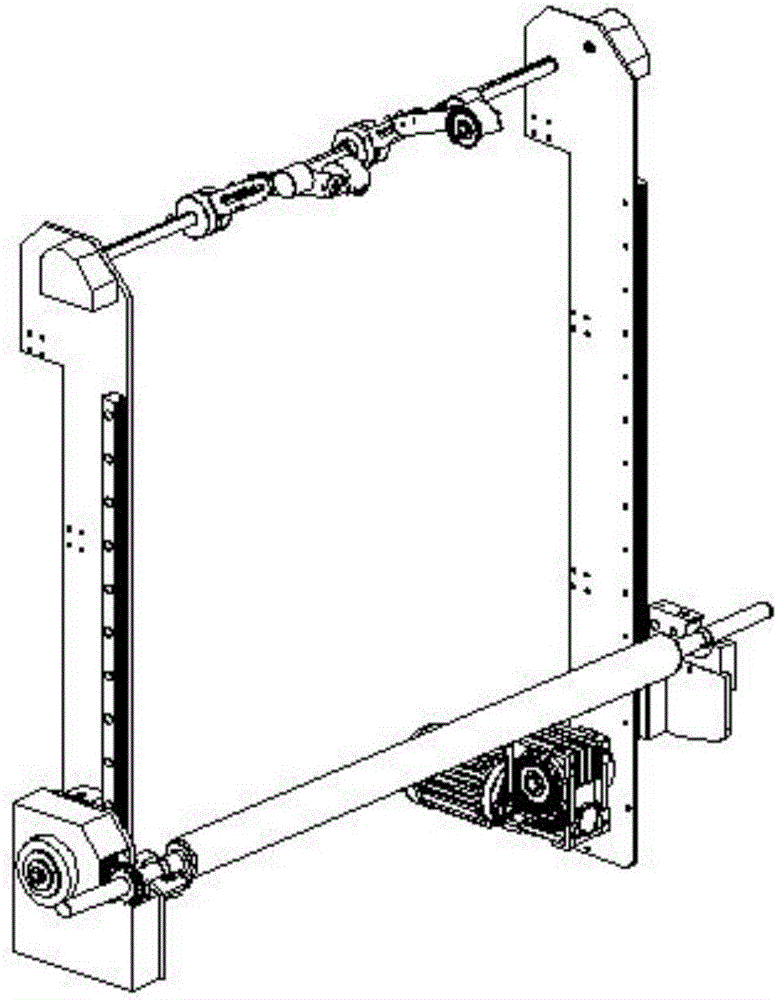

[0017] Such as Figure 1-4 Described, a kind of dual-track automatic film lifting device, comprises frame 1 and film roll bar 9, and described frame 1 is provided with lift guide rail 3, and lift guide rail 3 is provided with film roll bar 9, and described film roll bar 9 Slidingly fit with the lifting guide rail 3.

[0018] The lifting guide rail 3 includes a chain, the chain is driven by the motor 2, the top of the chain is provided with a suspension wheel, and the chain forms a lifting closed loop around the suspension wheel.

[0019] The number of said guide rails is two, which are respectively placed at the two ends of the film roll bar 9 and assembled and connected with the film roll bar 9 .

[0020] The film roll ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com