Three-layer co-extruded rapid bidirectionally stretched wide polyethylene composite film and preparation method thereof

A biaxial stretching and three-layer co-extrusion technology, which is applied in the field of three-layer co-extrusion rapid biaxial stretching wide-width polyethylene composite film and its preparation, can solve problems such as melt fracture, slow production speed, and large film thickness tolerance , to achieve the effects of not easy to break, reduce resin crystallization ability, and accurately control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

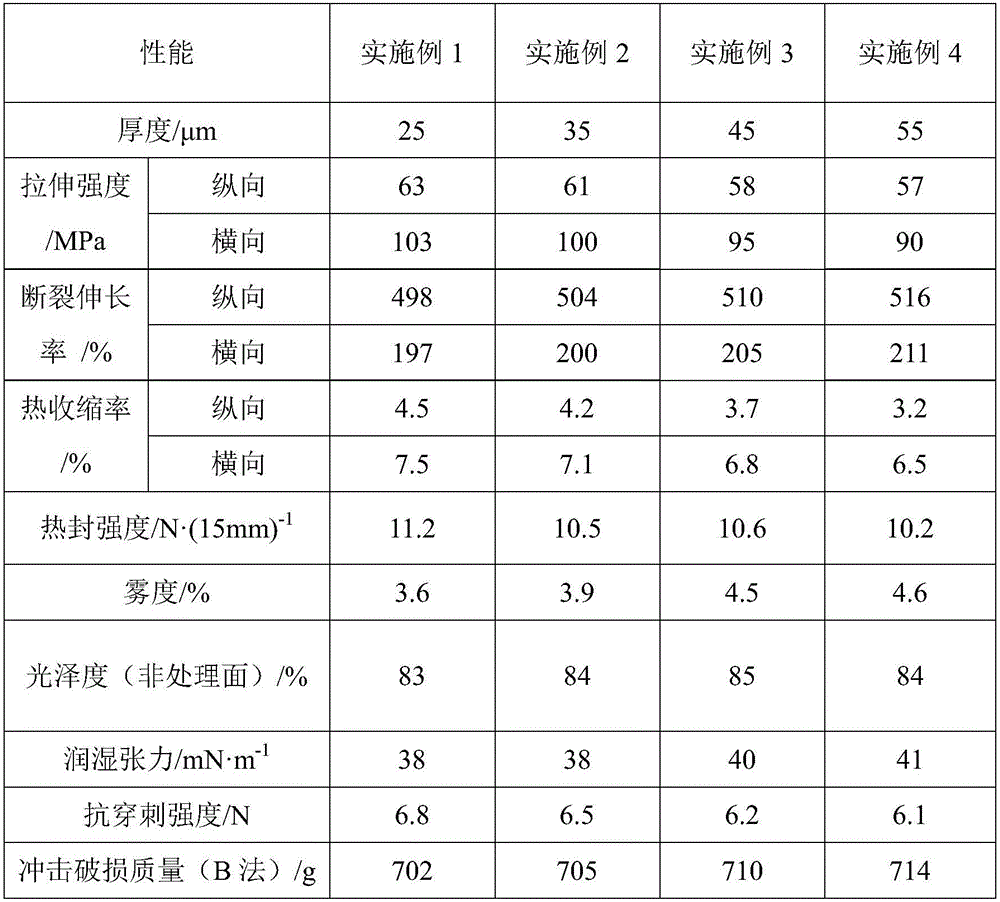

Examples

Embodiment 1

[0026] The mass percentages of selected raw materials are as follows:

[0027] The raw materials of the surface layer and the heat-sealing layer include the following components in mass percentage: 50% of low-density polyethylene (LDPE), 40% of metallocene polyethylene (m-LLDPE), 9% of ultra-high molecular weight polyethylene, and 0.5% slip agent, 0.5% antistatic agent. The raw material of the barrier layer is ethylene / vinyl alcohol copolymer (EVOH) resin.

[0028] According to the raw material formulations of the surface layer, barrier layer, and heat-sealing layer, the masterbatch is pretreated by batching, mixing, and drying. Each layer of resin material is heated in the extruder barrel and under the shear and push of the screw, melts, plasticizes, and heats to 190°C. After passing through the filter, the impurities are filtered out, and extruded into a thin film by the co-extrusion compound die. Thin flakes of fluid flow out. Under the action of the air knife in the cas...

Embodiment 2

[0030] The mass percentages of selected raw materials are as follows:

[0031]The raw materials of the surface layer and the heat-sealing layer include the following components in mass percentage: 55% of low-density polyethylene (LDPE), 37% of metallocene polyethylene (m-LLDPE), 6% of ultra-high molecular weight polyethylene, and 1.0% slip agent, 1.0% antistatic agent. The raw material of the barrier layer is ethylene / vinyl alcohol copolymer (EVOH) resin.

[0032] According to the raw material formulations of the surface layer, barrier layer, and heat-sealing layer, the masterbatch is pretreated by batching, mixing, and drying. Each layer of resin material is heated in the extruder barrel and under the shear and push of the screw, melts, plasticizes, and heats to 185°C. After passing through the filter, the impurities are filtered out, and extruded into a thin film by the co-extrusion compound die. Thin flakes of fluid flow out. Under the action of the air knife in the cast...

Embodiment 3

[0034] The mass percentages of selected raw materials are as follows:

[0035] The raw materials of the surface layer and the heat-sealing layer include the following components in mass percentage: 60% of low-density polyethylene (LDPE), 30% of metallocene polyethylene (m-LLDPE), 7% of ultra-high molecular weight polyethylene, and 1.5% slip agent, 1.5% antistatic agent. The raw material of the barrier layer is ethylene / vinyl alcohol copolymer (EVOH) resin.

[0036] According to the raw material formulations of the surface layer, barrier layer, and heat-sealing layer, the masterbatch is pretreated by batching, mixing, and drying. Each layer of resin material is heated in the extruder barrel and under the shear and push of the screw, melts, plasticizes, and heats to 180°C. After passing through the filter, the impurities are filtered out, and extruded into a thin film by the co-extrusion compound die. Thin flakes of fluid flow out. Under the action of the air knife in the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com