External circulation multi-effect evaporator for titanium dioxide waste acid

A multi-effect evaporator and titanium dioxide waste acid technology, applied in the chemical industry, can solve problems such as low energy consumption, and achieve the effects of low energy consumption, significant economic benefits, and a simple and effective process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

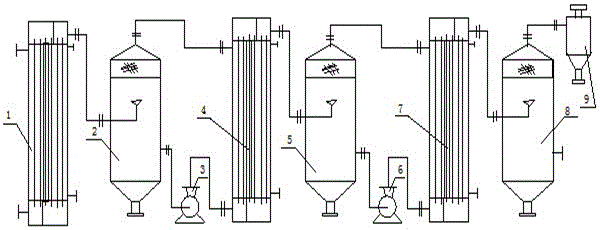

Image

Examples

Embodiment 1

[0022] Press the waste acid of titanium dioxide with an acid concentration of about 20% and a temperature of 50 degrees into the tube side of the first-effect heater 1, steam enters the shell side of the first-effect heater 1, and the waste acid flows back and forth in the multi-tube side. It exchanges heat with the steam in the shell side of the first-effect heater 1, the waste acid is heated, and is sent to the first-effect flash crystallization tank 2 through the waste acid outlet pipe of the first-effect heater 1. In the vacuum environment of the tank, the waste acid passes through The nozzle sprays into a mist, suddenly "flashing", a large amount of water in the waste acid evaporates to form water vapor, and the titanium dioxide waste acid is concentrated. As the concentration of the waste acid increases, it settles down, and the low-concentration waste acid rolls upwards, and the liquid layer Circulation is formed in the tank. In addition, due to the increased concentratio...

Embodiment 2

[0024] Press titanium dioxide waste acid with an acid concentration of about 30% and a temperature of 60 degrees into the tube side of the first-effect heater 1, steam enters the shell side of the first-effect heater 1, and the waste acid flows back and forth in the multi-tube side. It exchanges heat with the steam in the shell side of the first-effect heater 1, the waste acid is heated, and is sent to the first-effect flash crystallization tank 2 through the waste acid outlet pipe of the first-effect heater 1. In the vacuum environment of the tank, the waste acid passes through The nozzle sprays into a mist, suddenly "flashing", a large amount of water in the waste acid evaporates to form water vapor, and the titanium dioxide waste acid is concentrated. As the concentration of the waste acid increases, it settles down, and the low-concentration waste acid rolls upwards, and the liquid layer Circulation is formed in the tank. In addition, due to the increased concentration of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com