Compound antioxidant for feed and preparation method of compound antioxidant

A compound antioxidant and antioxidant technology, applied in animal feed, animal feed, application and other directions, can solve the problems of weak metal ion chelating ability, insufficient choice of emulsifier, poor antioxidant effect, etc., to avoid feed fat. Accelerates mass oxidation, reduces fat oxidative rancidity, and reduces water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

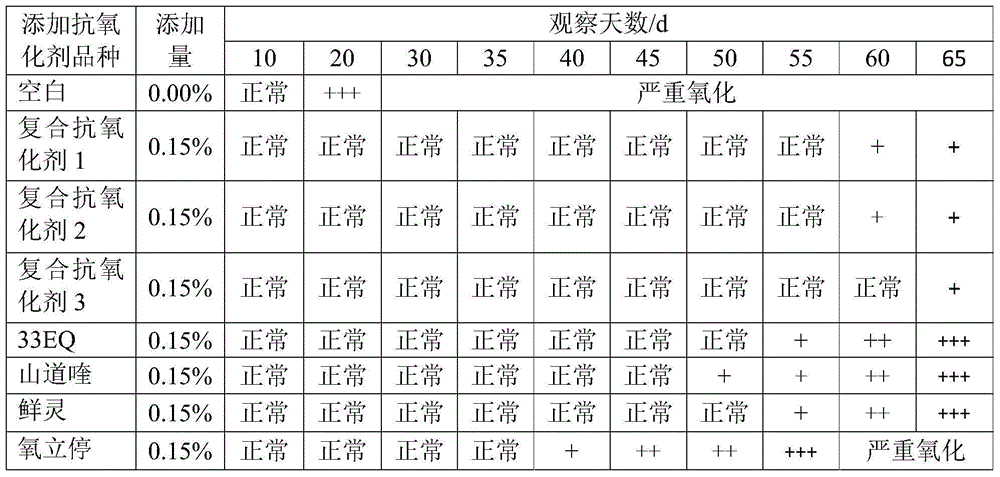

Examples

Embodiment 1

[0046] Compound Antioxidant 1

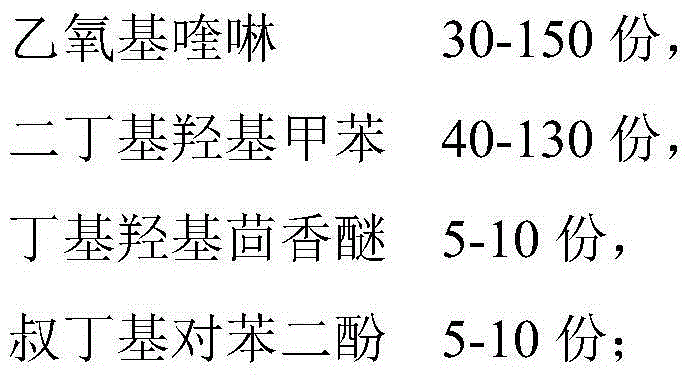

[0047] (1) Preparation of antioxidants

[0048] Weigh 80 parts of ethoxyquinoline (EQ), 90 parts of butylated hydroxytoluene (BHT), 5 parts of butylated hydroxyanisole (BHA) and 5 parts of tert-butylhydroquinone (TBHQ) in stainless steel for reaction In the kettle, heat to 65-75°C, fully dissolve into a liquid state, and stir evenly to obtain an oily liquid for use (by weight parts).

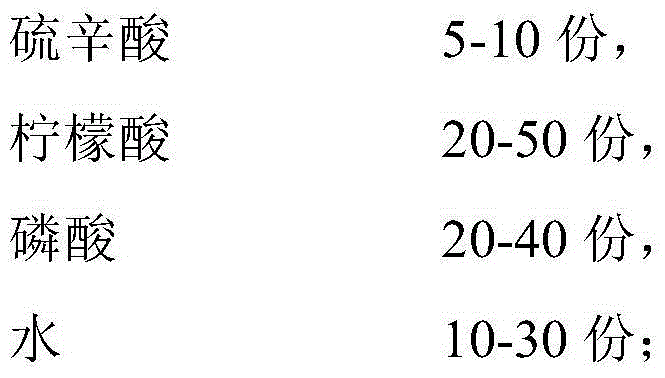

[0049] (2) Preparation of synergist

[0050] Weigh 10 parts of water, 50 parts of citric acid, and 5 parts of lipoic acid in a stainless steel reactor, heat to 65-75°C to dissolve them all, then add 30 parts of phosphoric acid, stir well and set aside.

[0051] (3) Emulsification and compounding

[0052] Transfer the material in (2) to the reaction kettle of the material in (1), add 3 parts of soybean lecithin, 805 parts of Tween and 15 parts of glyceryl monostearate, heat and keep it at 70°C, keep it for 5 minutes, and emulsify for 15 minutes to obtain The un...

Embodiment 2

[0054] Compound Antioxidant 2

[0055] (1) Preparation of antioxidants

[0056] Weigh 130 parts of ethoxyquinoline (EQ), 40 parts of butylated hydroxytoluene (BHT), 5 parts of butylated hydroxyanisole (BHA) and 5 parts of tert-butylhydroquinone (TBHQ) in stainless steel for reaction In the kettle, heat to 65-75°C, fully dissolve into a liquid state, and stir evenly to obtain an oily liquid for use (by weight parts).

[0057] (2) Preparation of synergist

[0058] Weigh 30 parts of water, 20 parts of citric acid, and 10 parts of lipoic acid in a stainless steel reactor, heat to 65-75°C to dissolve them all, then add 40 parts of phosphoric acid, stir well and set aside.

[0059] (3) Emulsification and compounding

[0060] Transfer the material in (2) to the reaction kettle of the material in (1), add 5 parts of soybean lecithin, 8010 parts of Tween and 10 parts of glyceryl monostearate, heat and keep it at 70°C, keep it for 10 minutes, and emulsify for 20 minutes to obtain Th...

Embodiment 3

[0062] Compound Antioxidant 3

[0063] (1) Preparation of antioxidants

[0064] Weigh 50 parts of ethoxyquinoline (EQ), 120 parts of butylated hydroxytoluene (BHT), 10 parts of butylated hydroxyanisole (BHA) and 5 parts of tert-butylhydroquinone (TBHQ) in stainless steel for reaction In the kettle, heat to 75°C, fully dissolve into a liquid state, and stir evenly to obtain an oily liquid for use (by weight parts).

[0065] (2) Preparation of synergist

[0066] Weigh 30 parts of water, 50 parts of citric acid, and 5 parts of lipoic acid in a stainless steel reactor, heat to 65-75°C to dissolve them all, then add 40 parts of phosphoric acid, stir well and set aside.

[0067] (3) Emulsification and compounding

[0068] Transfer the material in (2) to the reaction kettle of the material in (1), add 5 parts of soybean lecithin, 8010 parts of Tween and 20 parts of glyceryl monostearate, heat and keep it at 65°C, keep it for 10 minutes, and emulsify it for 20 minutes to obtain Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com