A high-uniformity impedance plate and its production method

A production method and uniformity technology, applied in the field of high-uniformity impedance plates, can solve problems such as system failure, low dielectric thickness, impedance deviation, etc., and achieve the effect of preventing layer deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of 12-layer circuit board production method, such as Figure 1-3 shown, including the following steps:

[0035] Lamination;

[0036] drilling;

[0037] Copper plating once;

[0038] outer dry film;

[0039] Secondary copper plating;

[0040] etched copper;

[0041] Solderproof.

[0042] The above pressing process includes

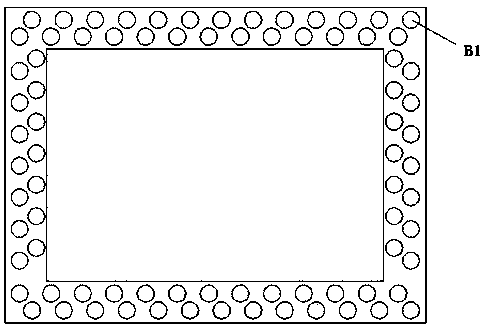

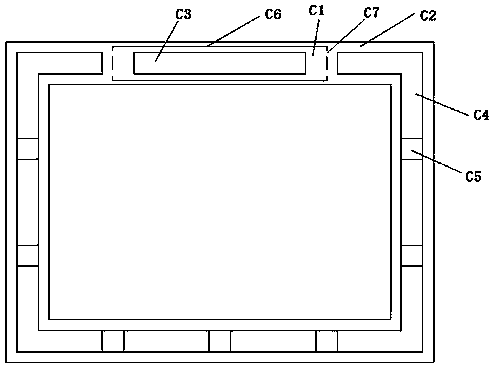

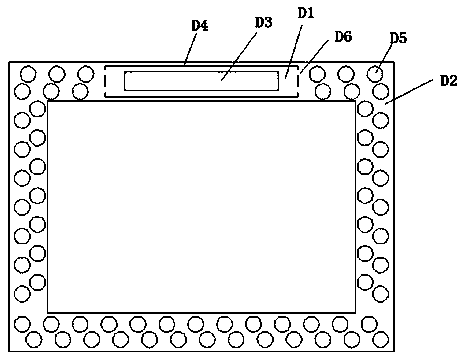

[0043] a. Provide two B-type plates, several C-type plates and D-type plates;

[0044] b. Pre-laminated boards and laminated boards;

[0045] c. Use a PE punching machine to punch PE holes on the edge of the 12-layer circuit board;

[0046] d. Position the 12-layer circuit board through the above-mentioned PE punching holes, and use a fusion machine to perform contact point fusion on the edge of the 12-layer circuit board. The fusion temperature is 260°C and the fusion time is 99s;

[0047] e. Riveting, positioning and riveting the 12-layer circuit board on the riveting machine using the above-mentione...

Embodiment 2

[0059] This embodiment provides a method for producing a 16-layer circuit board, the process of which is consistent with that of Embodiment 1.

[0060] Its pressing process includes

[0061] a. Provide two C-type plates, several B-type plates and D-type plates;

[0062] b. Pre-laminated boards and laminated boards;

[0063] c. Use a PE punching machine to punch PE holes on the edge of the 16-layer circuit board;

[0064] d. Position the 16-layer circuit board through the above-mentioned PE punching holes, and use a fusion machine to perform contact point fusion on the edge of the 16-layer circuit board. The fusion temperature is 235°C and the fusion time is 89s;

[0065] e. Riveting, positioning and riveting the 16-layer circuit board on the riveting machine using the above-mentioned PE punching holes;

[0066] f. Align the fused, riveted and reinforced 16-layer circuit board on the pressing machine for heating and pressing.

[0067] In the present embodiment, the drilling...

Embodiment 3

[0071] This embodiment provides a method for producing a 20-layer circuit board, the process of which is consistent with that of Embodiment 1.

[0072] Its pressing process includes

[0073] a. Provide two C-type plates, several B-type plates and D-type plates;

[0074] b. Pre-laminated boards and laminated boards;

[0075] c. Use a PE punching machine to punch PE holes on the edge of the 20-layer circuit board;

[0076] d. Position the 20-layer circuit board through the above-mentioned PE punching, and use a fusion machine to perform contact point fusion on the edge of the 20-layer circuit board. The fusion temperature is 290°C and the fusion time is 115s;

[0077] e. Riveting, positioning and riveting the 20-layer circuit board on the riveting machine using the above-mentioned PE punching holes;

[0078] f. Heat and press the fused and riveted 20-layer circuit board on the pressing machine.

[0079] In the present embodiment, the drilling process is carried out in the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com