LED driving control circuit, control device and control method

A LED drive and control circuit technology, applied in lighting devices, electric light sources, electrical components, etc., can solve the problems of incompatibility with high and low voltage input, large power loss, poor compatibility, etc., to achieve strong practicability, high compatibility, The effect of ingenious circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

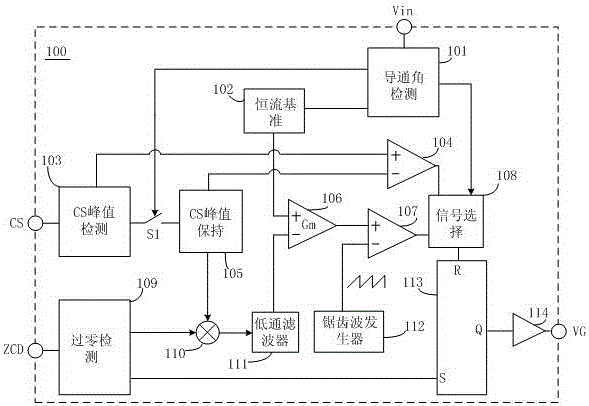

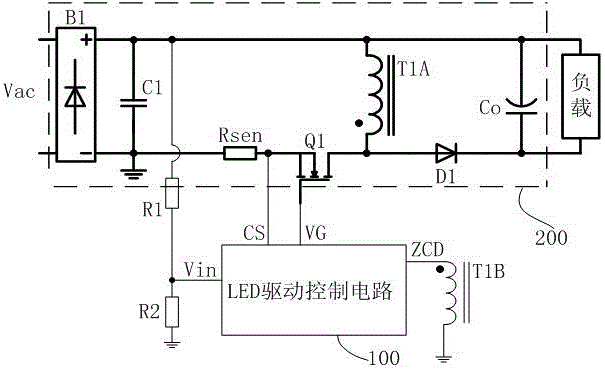

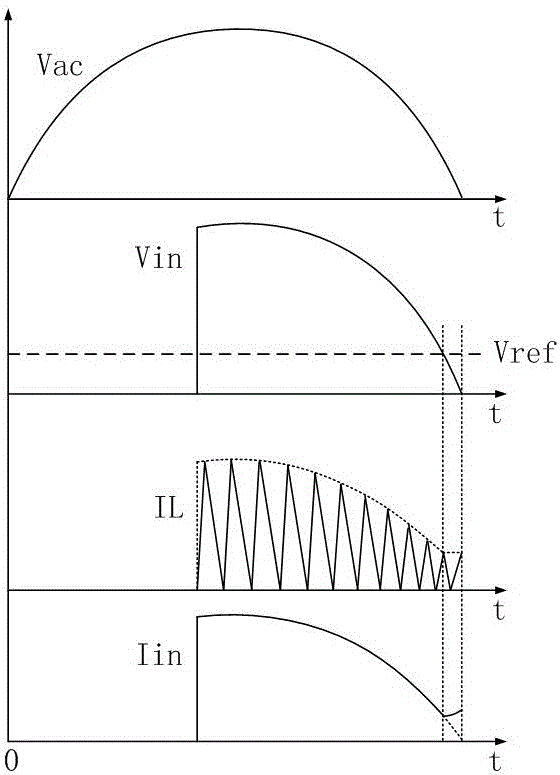

[0032] like figure 1 As shown, the LED drive control circuit 100 proposed by the present invention includes: a conduction angle detection circuit 101, a constant current reference circuit 102, a CS peak detection circuit 103, a CS peak hold circuit 105, a switch S1, a zero-crossing detection circuit 109, a first Comparator 107, second comparator 104, error amplifier 106, multiplier 110, low-pass filter 111, sawtooth wave generator 112, signal selection circuit 108, RS flip-flop 113 and switch drive circuit 114, the specific circuit connection relationship is : the input end of the conduction angle detection circuit 101 is connected to the main circuit, receives the input voltage rectified by the main circuit, and outputs three roads, one road is connected with the signal selection circuit 108, and the other road is connected with the constant current reference circuit 102, One path is connected to the switch S1, the input end of the CS peak detection circuit 103 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com