A kind of laser annealing device and annealing method thereof

A laser annealing and annealing technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of reduced scanning uniformity, inability to adjust the relative position and spot size, incident angle changes, etc., to improve annealing performance and The effect of ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with accompanying drawing:

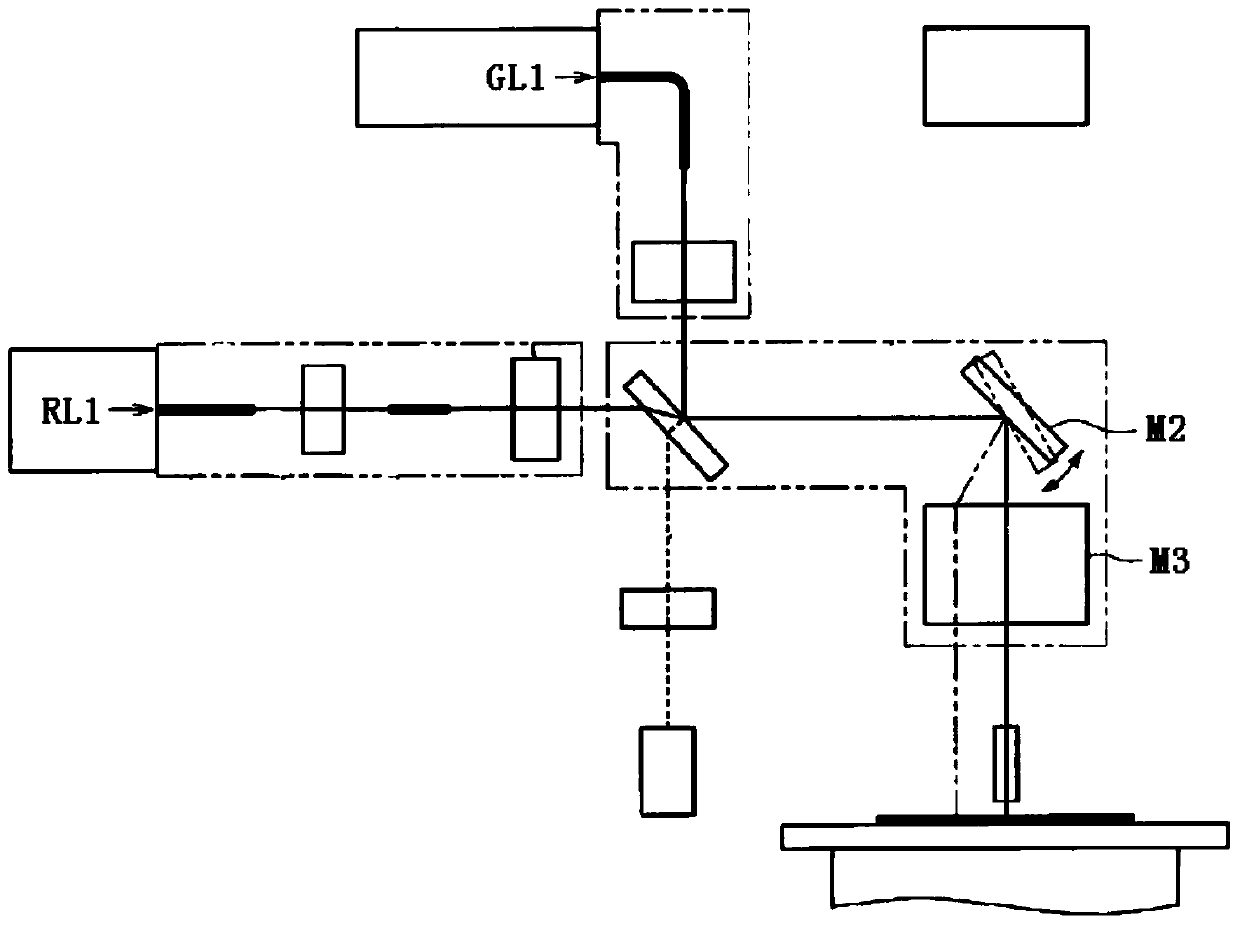

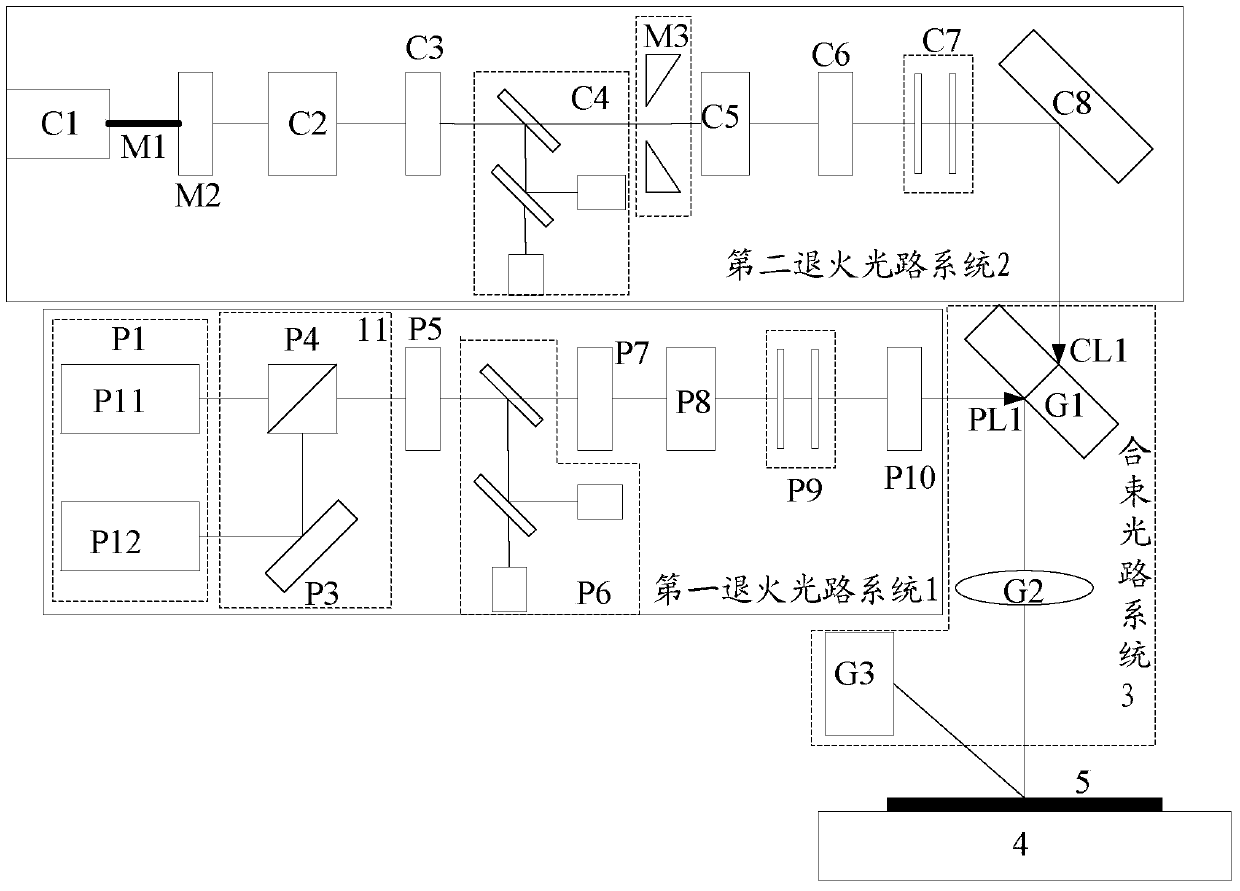

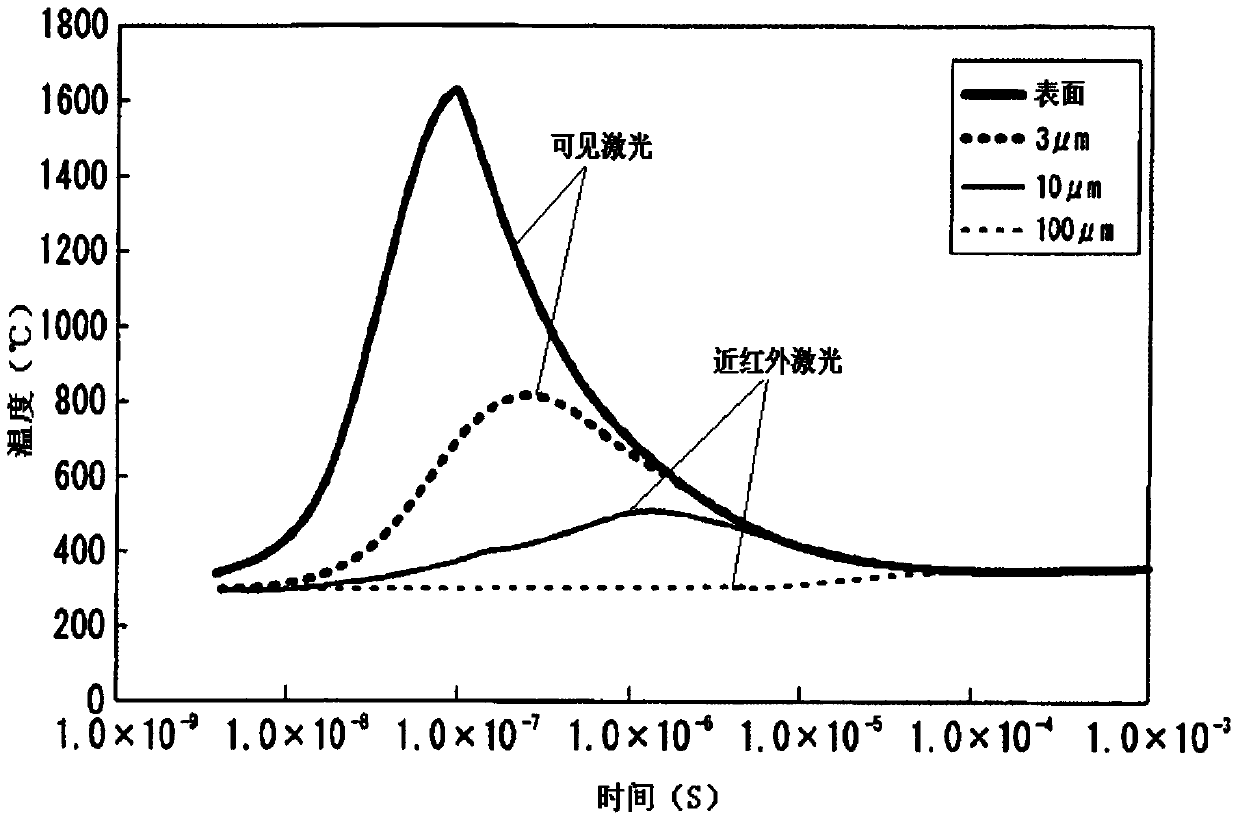

[0042] Such as figure 2 As shown, the present invention provides a laser annealing device, including a first annealing optical path system 1, a second annealing optical path system 2 and a beam combining optical path system 3, wherein the first annealing optical path system 1 includes a visible laser light source P1, and a visible laser light source P1 The corresponding visible laser light path system and the first energy monitoring unit P6; the second annealing light path system 2 includes a near-infrared laser light source C1, a near-infrared laser light path system corresponding to the near-infrared laser light source C1, a second energy monitoring unit C4 and an energy adjustment Unit M3; the near-infrared laser optical path system includes a near-infrared laser light source position adjustment unit M2; the beam combining optical path system 3 is arranged after the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com