A Hole Opening Method for Rare Metal Thin-walled Tubes

A technology for rare metal and thin-walled tubes, which is applied in the field of opening metal tubes and rare metal thin-walled tubes. It can solve the problems of large residual stress, large diameter and thick openings, and difficulty in large-area openings. Effects of reducing deformation, avoiding oxidation, and reducing residual processing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Titanium tube opening:

[0033] Step 1. Rare metal tube 1 (material: titanium, specification: length 150mm);

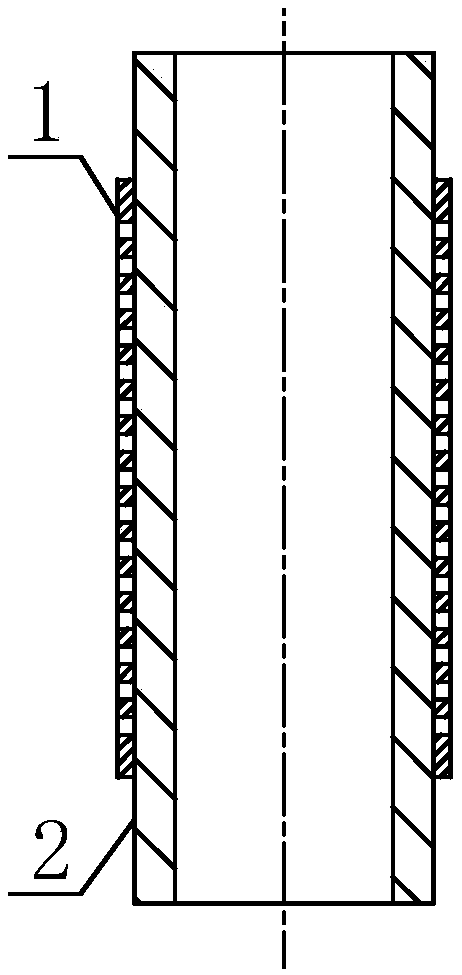

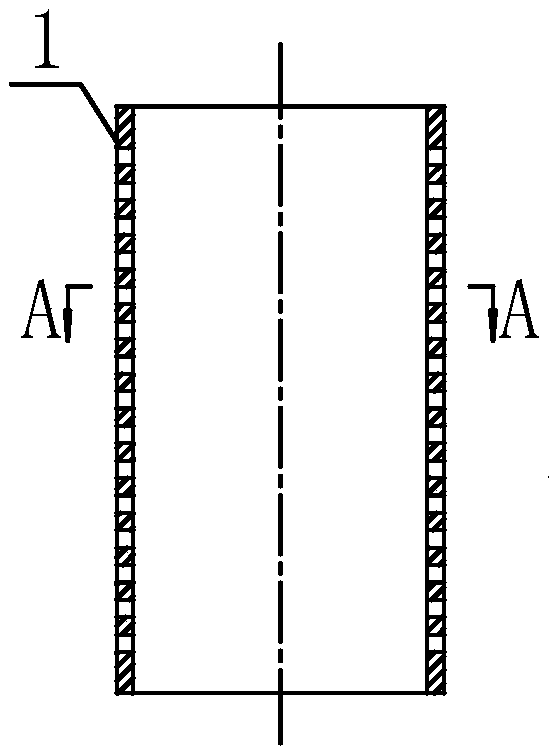

[0034] Step 2, cutting the steel pipe 2 (the material is: steel, the specification is: length 200mm), the inner diameter of the car steel pipe 2 to Both ends of the car are flush;

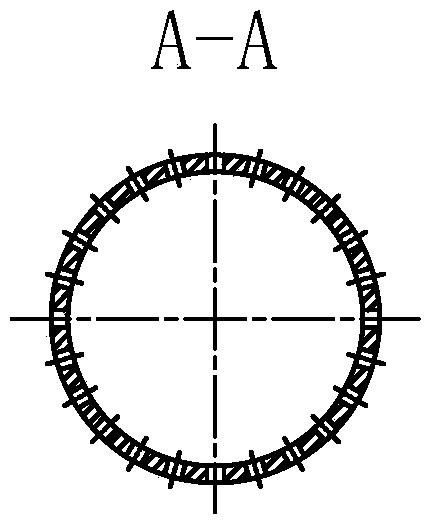

[0035] Step 3: Use an oxyacetylene flame to uniformly heat the rare metal tube 1 to 180° C. to 200° C. During the heating process, do not stay in one place for too long to avoid local oxidation. The heated rare metal pipe 1 is completely inserted into the outside of the unheated steel pipe 2, and the distance between the two ends of the rare metal pipe 1 and the two ends of the steel pipe 2 is 25mm. Such as figure 1 As shown, according to the drawing processing requirements of the rare metal tube 1, on the rare metal tube 1, use the vertical machining center to carry out 240 Hole processing, during the processing, it is necessary to ensure that each hole on the rare meta...

Embodiment 2

[0039] Slotted zirconium tube opening:

[0040] Step 1. Cut the lower plate material (material: zirconium, specification: 490×300×3mm), and form it into a rare metal tube 1 (specification: length 300mm);

[0041] Step 2: Cut the lower plate material (material: steel, specification: 462×350×12mm), and form it into a steel pipe 2 (specification: length 200mm), the inner diameter of the car steel pipe 2 to Both ends of the car are flush;

[0042] Step 3: Use an oxyacetylene flame to uniformly heat the rare metal tube 1 to 180° C. to 200° C. During the heating process, do not stay in one place for too long to avoid local oxidation. The heated rare metal pipe 1 is completely inserted into the outside of the unheated steel pipe 2, and the distance between the two ends of the rare metal pipe 1 and the two ends of the steel pipe 2 is 25 mm. Such as figure 1 As shown, according to the drawing processing requirements of the rare metal tube 1, on the rare metal tube 1, use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com