In-mold label material and preparation method thereof as well as in-mold label and packaging container

A technology for in-mold labels and packaging containers, which is applied in the direction of instruments, identification devices, adhesive additives, etc., can solve the problems of limiting the use of substrate layer materials, limiting the variety of labels, and difficult control of the thickness of each layer, so as to improve adhesion Strength, enhancement of decorative effects, effects of improving quality and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A preparation method for an in-mold label material, the preparation method comprising the following steps:

[0053] 1) coating the mixed solution of adhesive and antistatic agent on the upper surface of the substrate layer to form the first mixed layer;

[0054] 2) On the lower surface of the substrate layer, spray the mixed solution of adhesive and antistatic agent and EVA to form the second mixed layer and EVA layer.

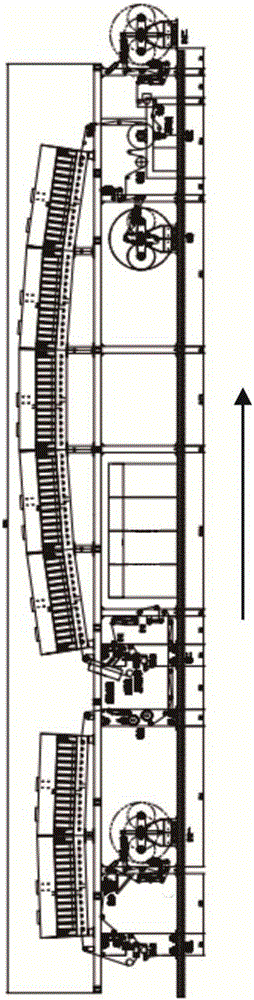

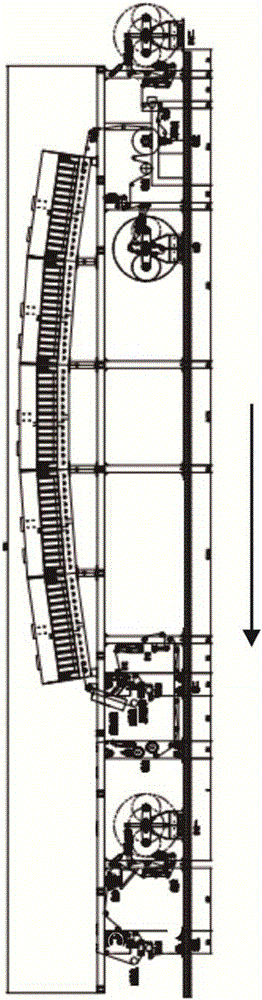

[0055] As a further solution, in the above preparation method, step 1) also includes forming a printable coating on the surface of the first mixed layer, wherein the first mixed layer and the printable coating are coated in the same direction or reversed by double-coating heads. Cloth machines are formed by synchronous coating on the upper surface of the substrate layer. Molding process see figure 1 .

[0056] As a further solution, in the above preparation method, the EVA layer and the second mixed layer in step 2) are formed on the lower surface by...

Embodiment 1

[0072] An in-mold label material comprising a polyethylene film as a substrate layer, the polyethylene film comprising an upper surface and a lower surface, and an EVA layer as a heat-sealing layer;

[0073] The upper surface of the polyethylene film is provided with a first mixed layer comprising a mixed solution of an adhesive and an antistatic agent, and the lower surface of the polyethylene film is provided with a second mixed layer comprising a mixed solution of an adhesive and an antistatic agent; The EVA layer of the sealing layer is coated on the second mixed layer;

[0074] Wherein, the mixed solution includes polyurethane adhesive and polyol fatty acid ester antistatic agent, and is formed by mixing the following components in parts by weight:

[0075]

[0076] The polyethylene film density that adopts in this embodiment is 0.92g / cm 3 , is blown film (IPE), its thickness is 90μm; its longitudinal stiffness is 18-20mN, and its transverse stiffness is 20-25mN;

[...

Embodiment 2

[0081] An in-mold label material comprising a polypropylene film as a substrate layer, the polypropylene film comprising an upper surface and a lower surface, and an EVA layer as a heat-sealing layer;

[0082] The upper surface of the polypropylene film is provided with a first mixed layer comprising a mixed solution of an adhesive and an antistatic agent, and the lower surface of the polypropylene film is provided with a second mixed layer comprising a mixed solution of an adhesive and an antistatic agent; The EVA layer of the sealing layer is coated on the second mixed layer;

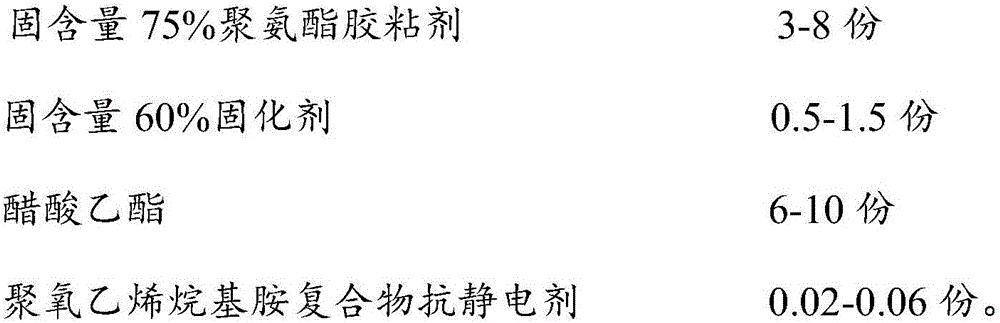

[0083] Wherein, the mixed solution of the present invention comprises acrylic acid copolymer and quaternary ammonium salt cationic surfactant, and is formed by mixing the following components in parts by weight:

[0084]

[0085] Mixed 3% antistatic agent in the EVA adopted in this embodiment;

[0086] The polypropylene film density that adopts in this embodiment is 0.91g / cm 3 , which is cast pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Longitudinal stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com