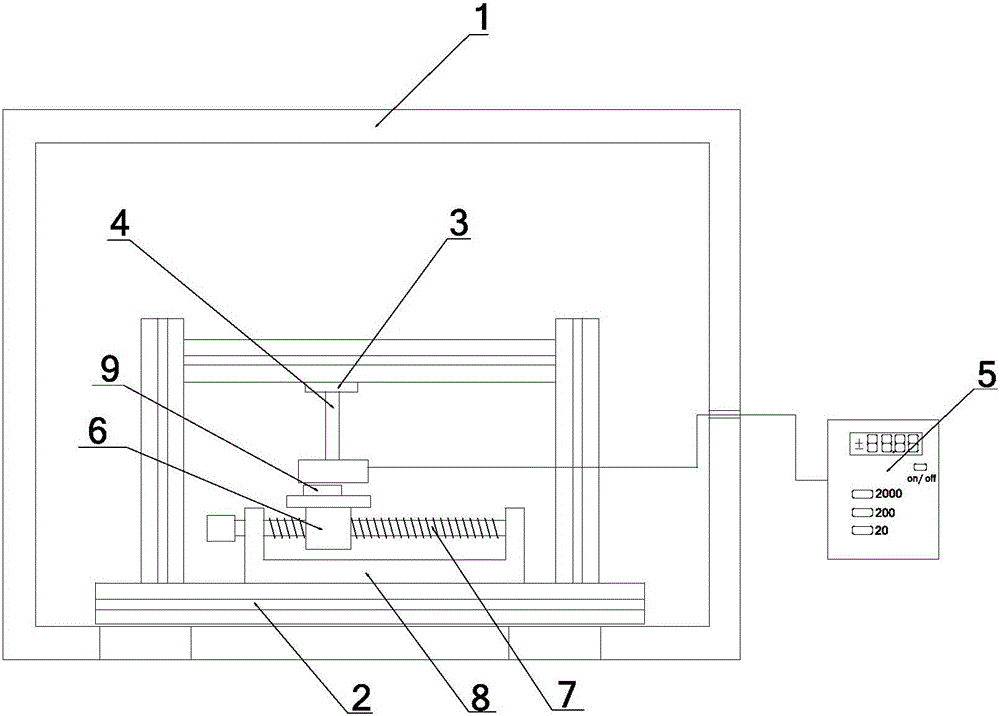

Medium manganese steel martensite phase transformation magnetic measurement device and realization method thereof

A martensitic phase transformation and measuring device technology, which is applied in the direction of magnetic properties measurement, material magnetic variables, etc., can solve the problems of measurement influence, inability to use medium manganese steel martensite magnetic measurement, and inability to judge the amount of internal martensite, etc. , to achieve the effect of high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] 1) Move the non-magnetic sliding table 6 to the designated initial position, place the sample 1 on the designated position of the non-magnetic sliding table 6 along the designated direction, and adjust the probe clamp 3 so that the magnetometer probe 4 is closer to and parallel to the sample 1 on samples;

[0034] 2) Move the sample 1 from left to right through the non-magnetic slide table 6, and record the magnetic field component value and coordinates of the fluxgate magnetometer digital display 5 at the same time, and obtain the one-dimensional distribution curve of the magnetic field component between coordinates 0 mm to 40 mm;

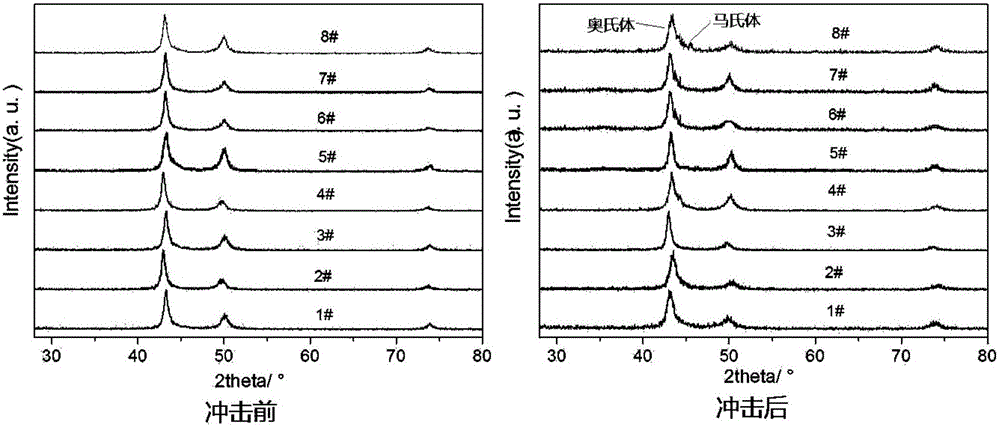

[0035] 3) Repeat the operations of 1) and 2), replace sample 1 with samples 2-8, and obtain the magnetic field component curves of a series of samples, such as figure 2 As shown, the size of these 8 medium manganese steel samples is the same, and the impact surface is also the same, only the composition is different.

[0036] Then, analyz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com