A circular air supply vertical foam generating device

A foam generating device, vertical technology, applied in the field of circular air supply vertical foam generating device, can solve the problems of poor foaming ability of foam generator, low foam outlet pressure, uneven foam distribution, etc., to increase the contact area , Simplify the supply method, improve reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

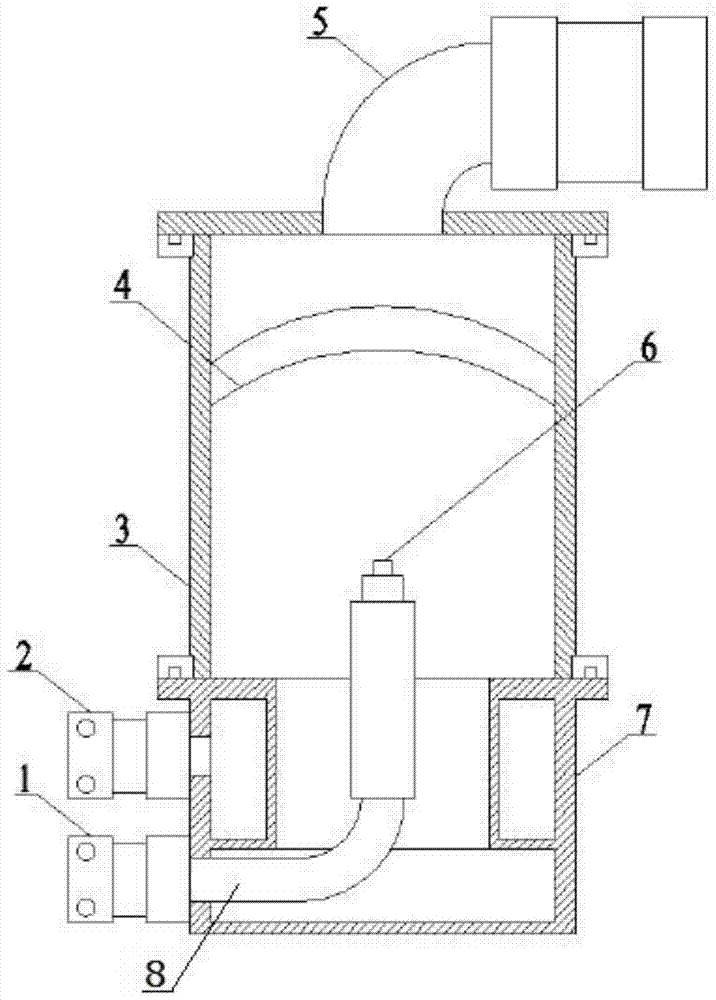

[0019] Such as figure 1 As shown, a circular air supply vertical foam generating device of the present invention includes a liquid supply joint 1, an air supply joint 2, a foaming cylinder 3, a foaming net 4, a foam transport pipeline 5, an atomizing nozzle 6 and a base 7.

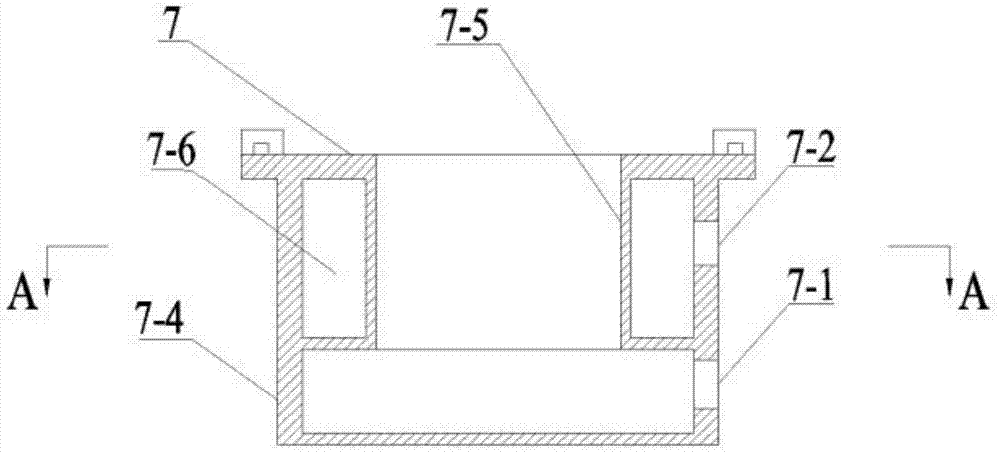

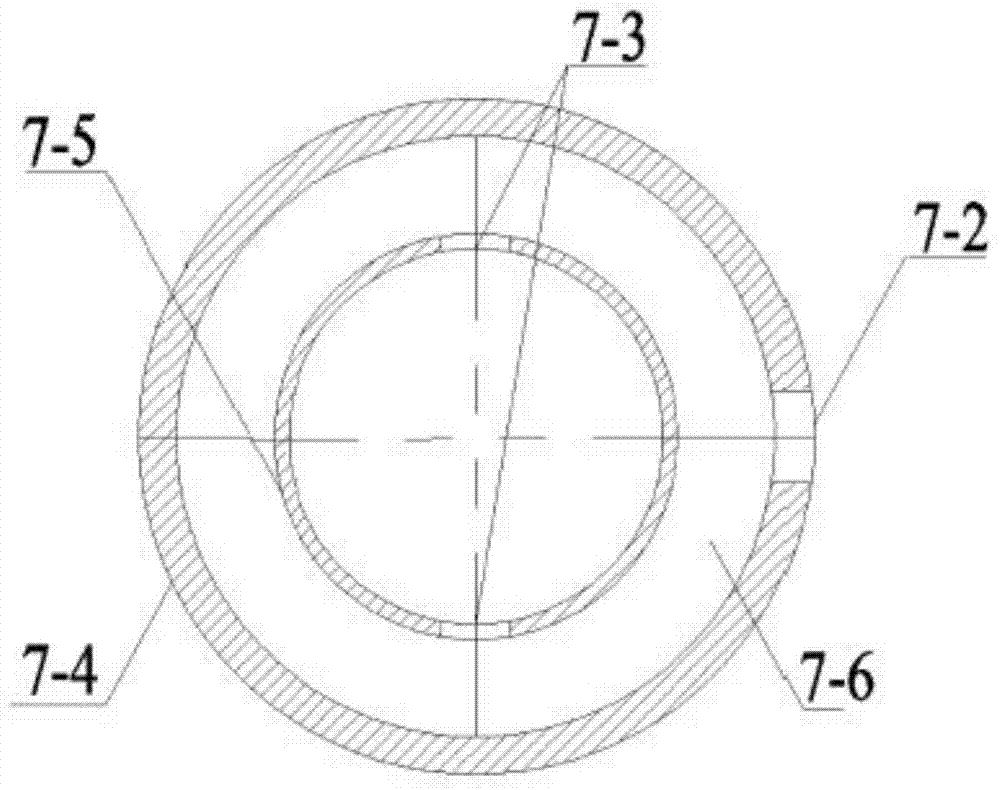

[0020] The base 7 is provided with a liquid supply joint 1 and an air supply joint 2. The upper end of the base 7 is connected to the lower end of the foaming cylinder 3 through a flange. The foaming cylinder 3 is an upright cylinder, and the height of the foaming cylinder 3 is The diameter of the foaming cylinder 3 is 1.5 to 2 times, and the atomizing nozzle 6 is arranged on the inner lower part of the foaming cylinder 3 at the central axis of the foaming cylinder 3, and the atomizing nozzle 6 passes through the liquid supply pipeline 8 and the liquid supply joint 1 connected, the atomization an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap