Testing apparatus for tensioning force under anchor for prestressed clamping type anchoring device

A technology of prestressed clips and tension testing, applied in tension measurement, measuring devices, force/torque/power measuring instruments, etc., can solve the problem of inability to achieve accurate evaluation of tension under the anchor of prestressed steel strands, and unable to take effective measures , Low detection accuracy and other issues, to achieve accurate identification, easy operation, and high capture accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

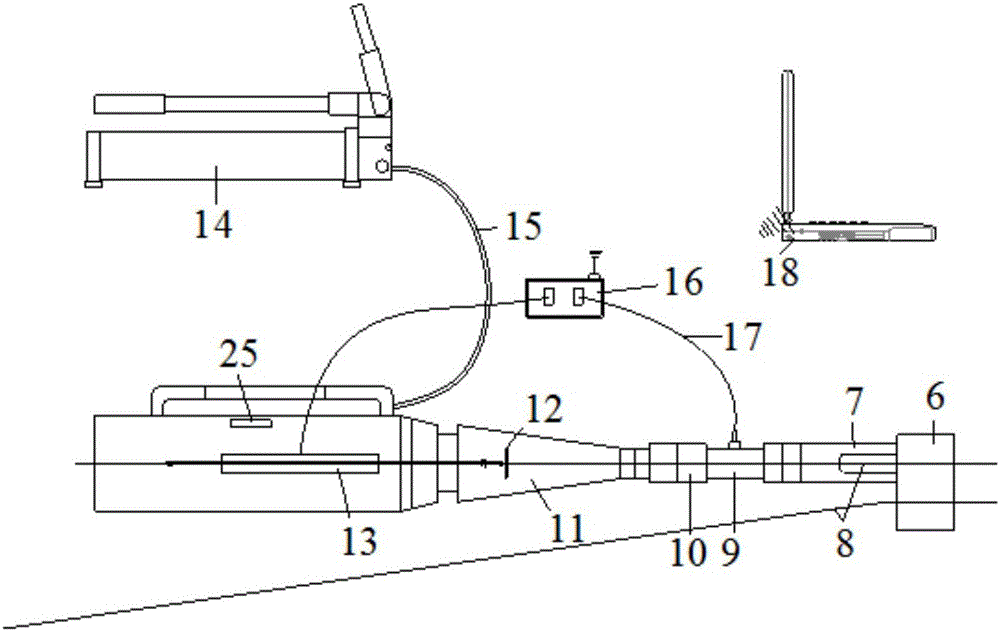

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

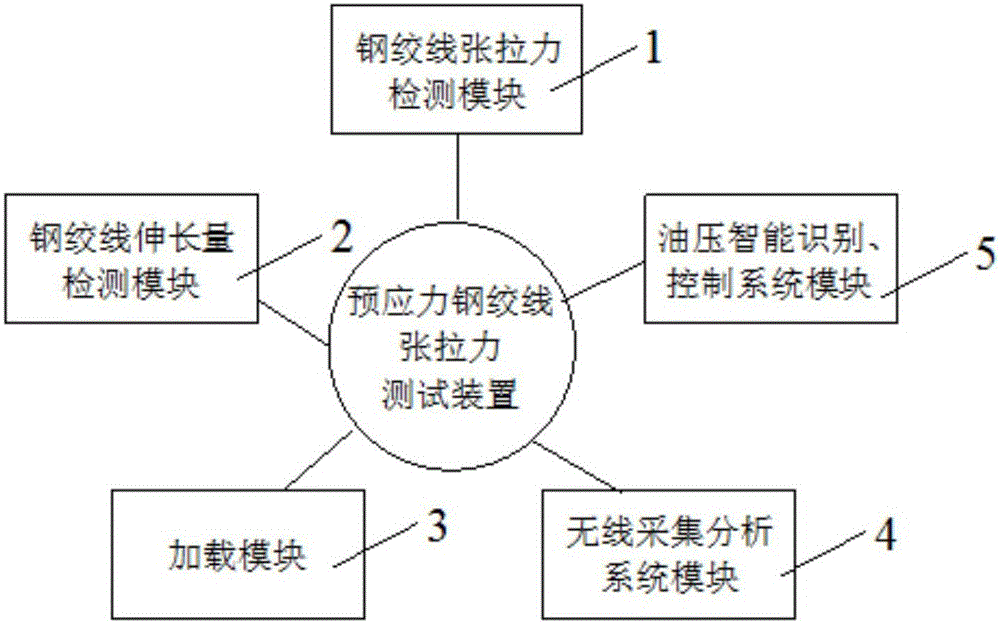

[0033] A prestressed steel strand tension test device mainly includes a steel strand tension detection module, a steel strand elongation detection module, a loading module, a wireless collection and analysis system module, and an oil pressure intelligent identification and control system module. Specifically, it includes clip limit device, strain gauge pressure sensor, high-precision displacement gauge, front clamp jack, manual hydraulic pump, wireless acquisition and analysis system controller, oil pressure intelligent identification and control device, and computer terminal.

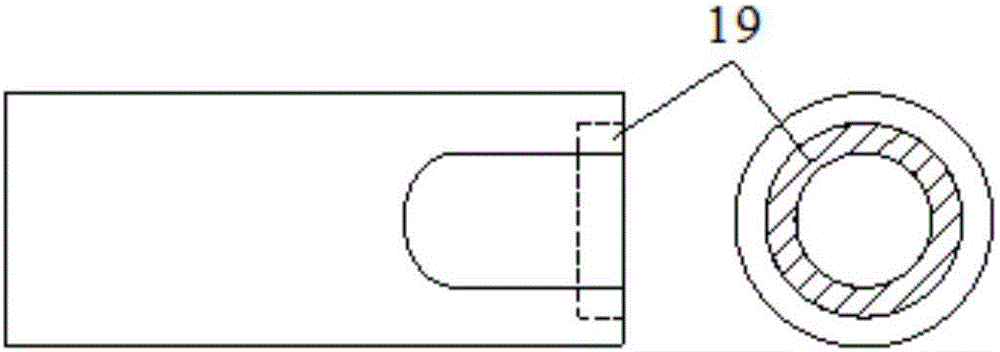

[0034] The clip limit device passes through a single prestressed steel strand, acts on the clip anchor and has no direct effect on the clip on the clip anchor. There is a limit groove on the clip limit device. To prevent excessive prolapse of the clip.

[0035] A strain gauge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com