Method For Detecting Leaks In Intake Manifold

An intake manifold and intake valve technology, which is applied in electrical control, engine starting, engine motor starting, etc., can solve problems such as reduced efficiency, complicated leakage diagnosis, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

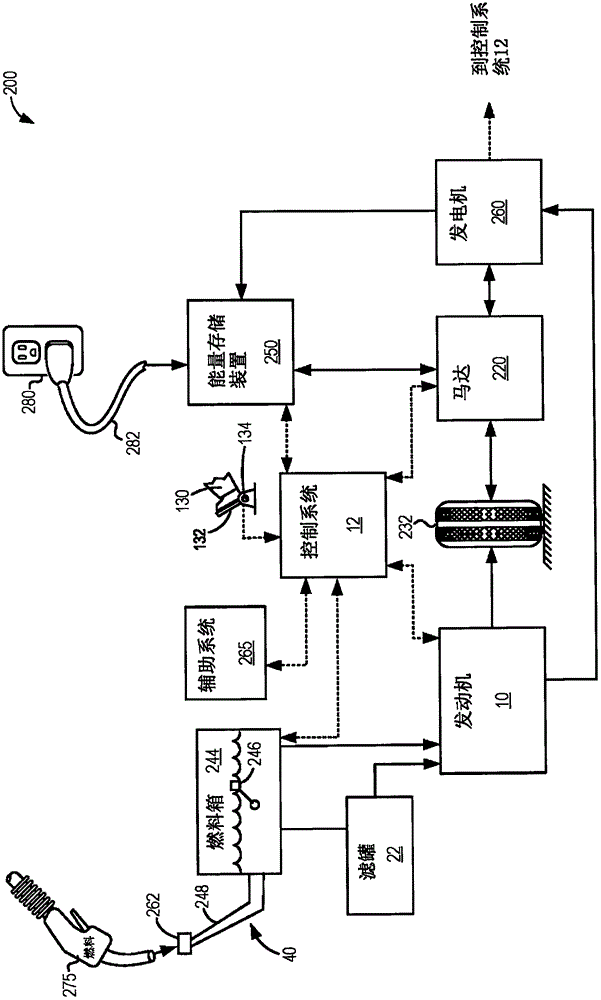

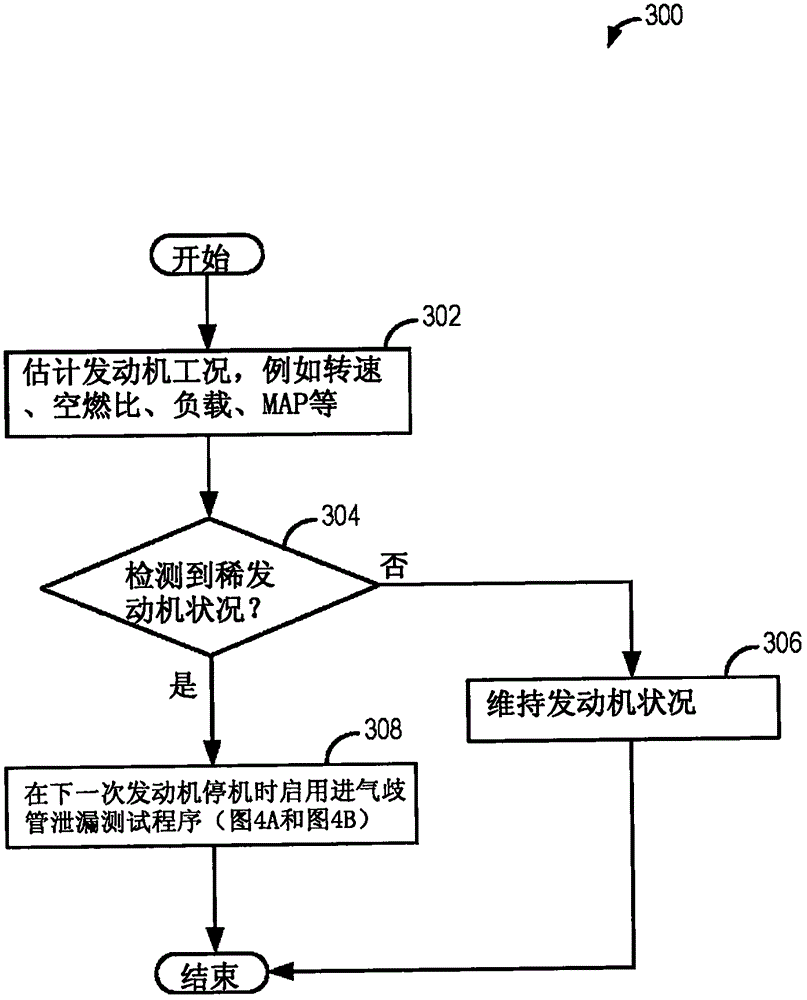

[0016] The following description refers to methods used to determine whether an engine system such as figure 1 Systems and methods for leaks in an intake manifold of an example engine system). The engine system may be a hybrid vehicle propulsion system such as figure 2 part of the hybrid vehicle system). The leak test may be initiated in the engine in response to detecting a lean engine condition in the engine ( image 3 ). Thus, leak testing may include, by closing the intake throttle and terminating airflow from other sources, when the engine is shut down to rest ( Figure 4A , Figure 4B ) creates a vacuum in the intake manifold. All intake valves of all cylinders of the engine may be fully closed in response to vacuum in the intake manifold reaching a predetermined level. In camless engines, the intake valve may be adjusted closed via an electromechanical actuator. In a hybrid vehicle, the intake valve is regulated to close ( Figure 5 ). Alternative methods of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com