A mobile formwork for the construction of a single-rectangular-top-closed water conservancy aqueduct

A mobile formwork, closed type technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

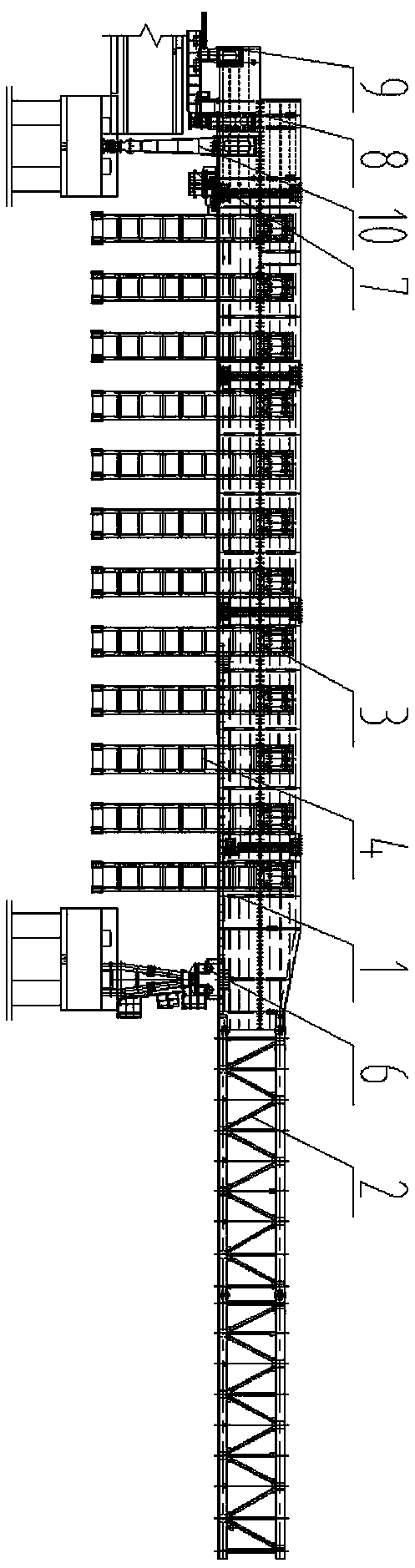

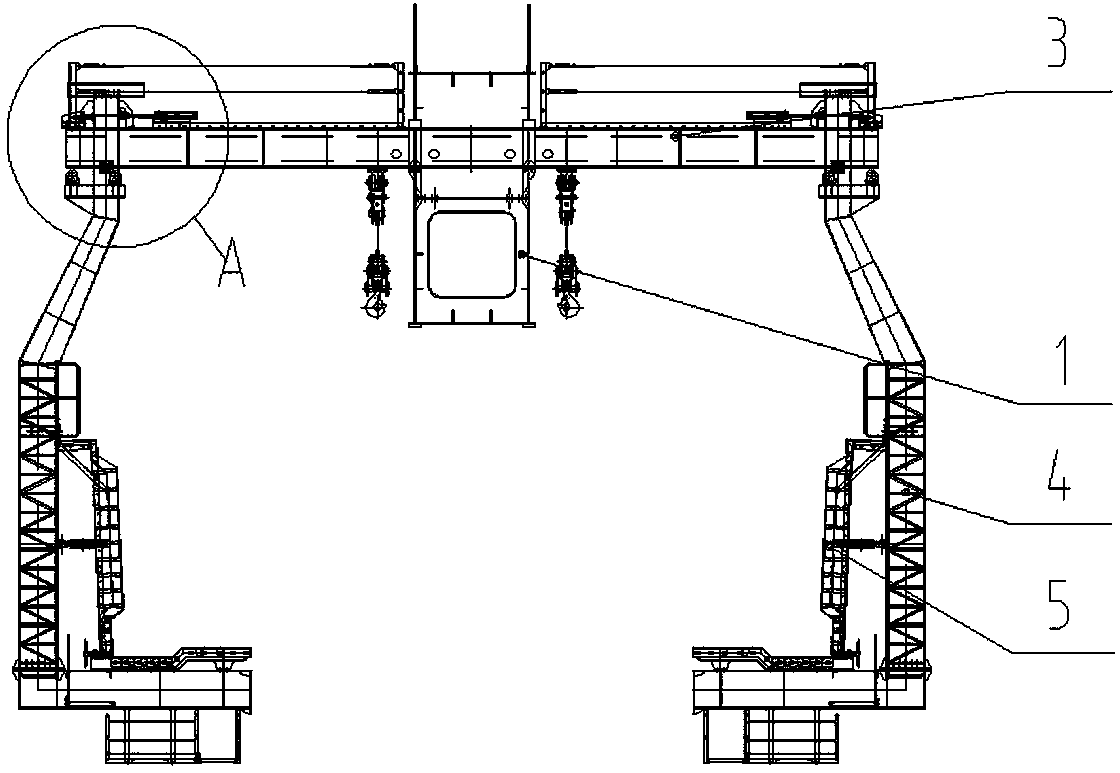

[0053] A movable formwork for the construction of a single rectangular top-open closed water conservancy aqueduct, such as Figure 1-5 As shown, it includes the outer beam system, the inner beam system and the lifting system. The outer beam system includes the main beam 1, the guide beam 2, the cantilever beam 3, the outer rib 4, the outer formwork 5, the first leg 6, and the second leg 7, 3A leg 8, 3B leg 9, 4 leg 10, the main beam 1 is a box-shaped structure, and the main beam 1 includes multiple sections, and each section is connected by a gusset plate to form a whole , The main beam 1 is placed longitudinally, the left end of the main beam 1 is provided with a counterweight 1-1, the right end is connected with a guide beam 2, the guide beam 2 is a truss structure, the guide beam 2 includes three sections, and nodes pass through the sections The slabs are connected as a whole. A cantilever beam 3 is connected above the main beam 1. The cantilever beam 3 and the main beam 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com