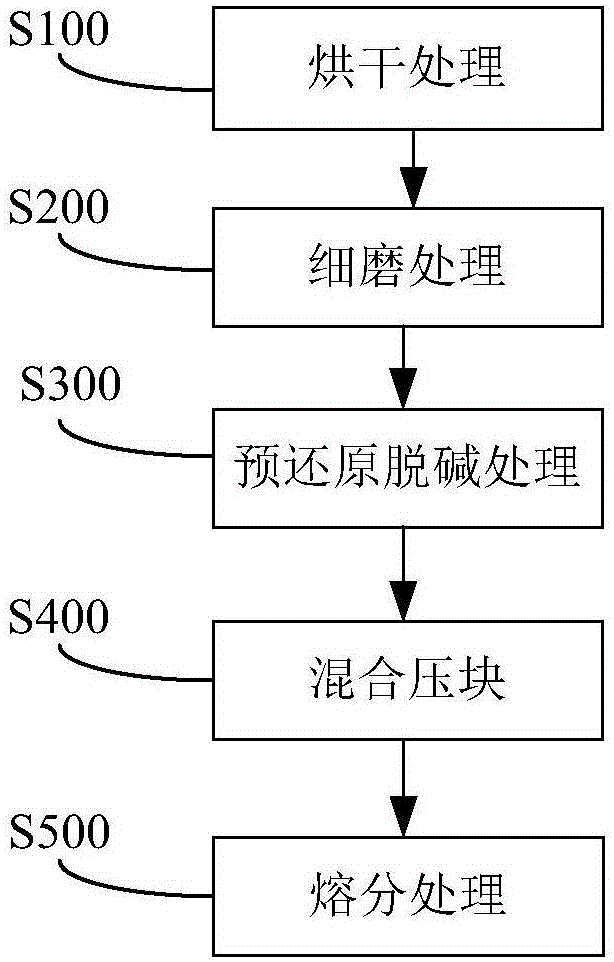

Method and system for treating red mud

A technology of red mud and dealkalized red mud, which is applied in the fields of metallurgy and energy, can solve problems such as easy ringing of equipment, low metallization rate, and difficulty in metallizing pellets, so as to improve reducibility, important economic benefits, and recovery rate and the effect of high metallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

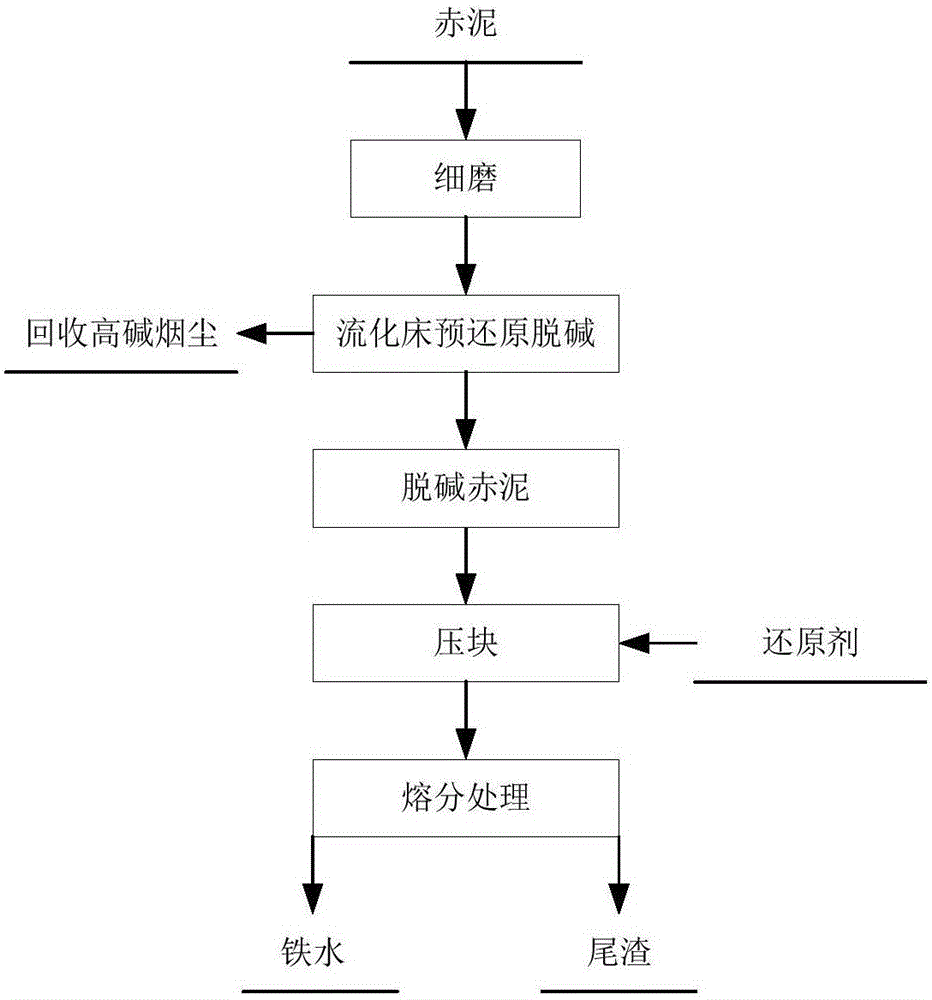

Embodiment 1

[0052] A certain red mud, TFe is 30.29%, Na 2 O is 5.22%. The red mud is dried and finely ground to -0.043mm, and the red mud ore powder is sent into the fluidized bed for pre-reduction dealkalization. In the fluidized bed reducing gas (H 2 +CO) was 70%, the gas temperature was 1020° C., and the reaction time was 40 minutes. The sodium content of the red mud after dealkalization is 0.28%. After dealkalization, the red mud is mixed with 10% reduced coal, mixed evenly and then pressed into blocks. The obtained clumps are put into the melting furnace, and the temperature of the melting furnace is 1550°C , the deep reduction and melting time of the agglomerate in the melting furnace is 60min, and the molten iron and tailings are finally separated. The iron grade in the molten iron is 97%, and the iron recovery rate is 92%.

Embodiment 2

[0054] A certain red mud, TFe is 30.29%, Na 2 O is 5.22%. The red mud is dried and finely ground to -0.043mm, and the red mud ore powder is sent into the fluidized bed for pre-reduction dealkalization. In the fluidized bed reducing gas (H 2 +CO) was 75%, the gas temperature was 1020° C., and the reaction time was 30 minutes. The sodium content of the red mud after dealkalization is 0.30%. After the dealkalization, the red mud is mixed with 8% reduced coal, mixed evenly and then pressed into blocks. The obtained agglomerates are put into the melting furnace, and the temperature of the melting furnace is 1500°C , the deep reduction and melting time of the agglomerate in the melting furnace is 60min, and the molten iron and tailings are finally separated. The iron grade in the molten iron is 97%, and the iron recovery rate is 91%.

Embodiment 3

[0056] A certain red mud, TFe is 30.29%, Na 2 O is 5.22%. The red mud is dried and finely ground to -0.043mm, and the red mud ore powder is sent into the fluidized bed for pre-reduction dealkalization. In the fluidized bed reducing gas (H 2 +CO) was 75%, the gas temperature was 1020° C., and the reaction time was 30 minutes. The sodium content of the red mud after dealkalization is 0.30%. After dealkalization, the red mud is mixed with 8% reduced coal, mixed evenly and then pressed into briquettes. , the deep reduction and melting time of the agglomerate in the melting furnace is 40 minutes, and the molten iron and tailings are finally separated. The iron grade in the molten iron is 97%, and the iron recovery rate is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com