A pre-winding device for winding tape

A pre-winding and tape technology, applied in the directions of packaging, coiling, transportation and packaging, etc., can solve the problems of steel pipes affecting the winding stability, not in the same line, and anti-corrosion heat shrinkable tapes being eccentric, so as to improve the winding quality. , Improve stability, design scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

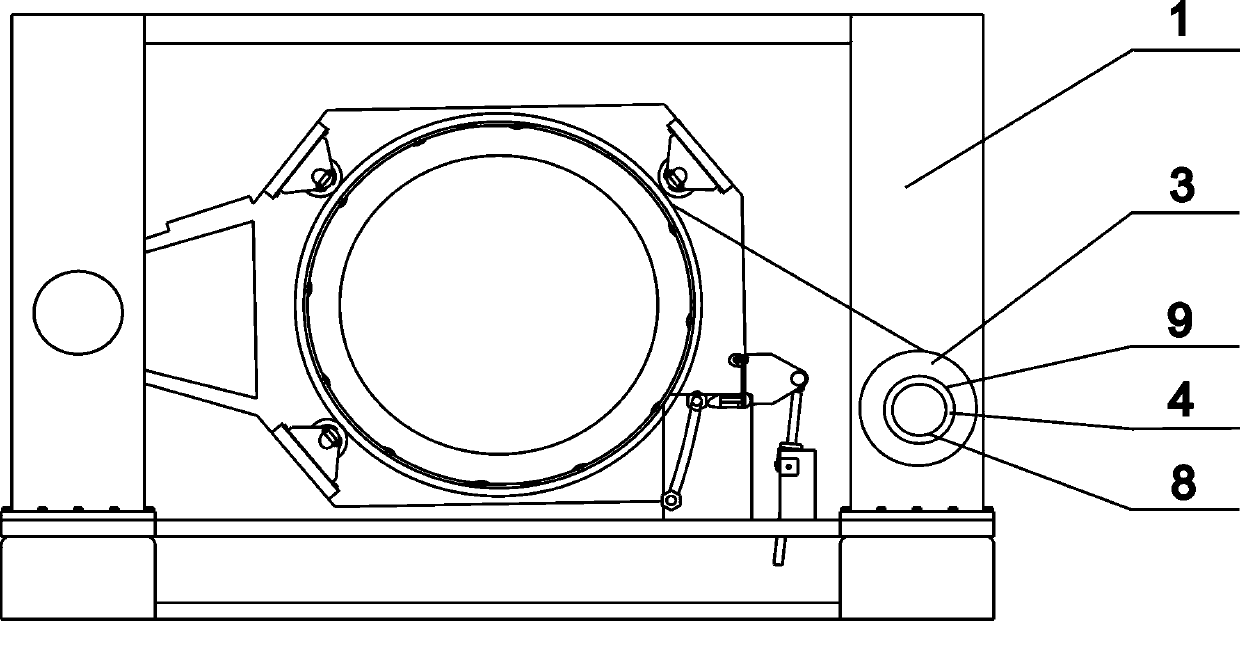

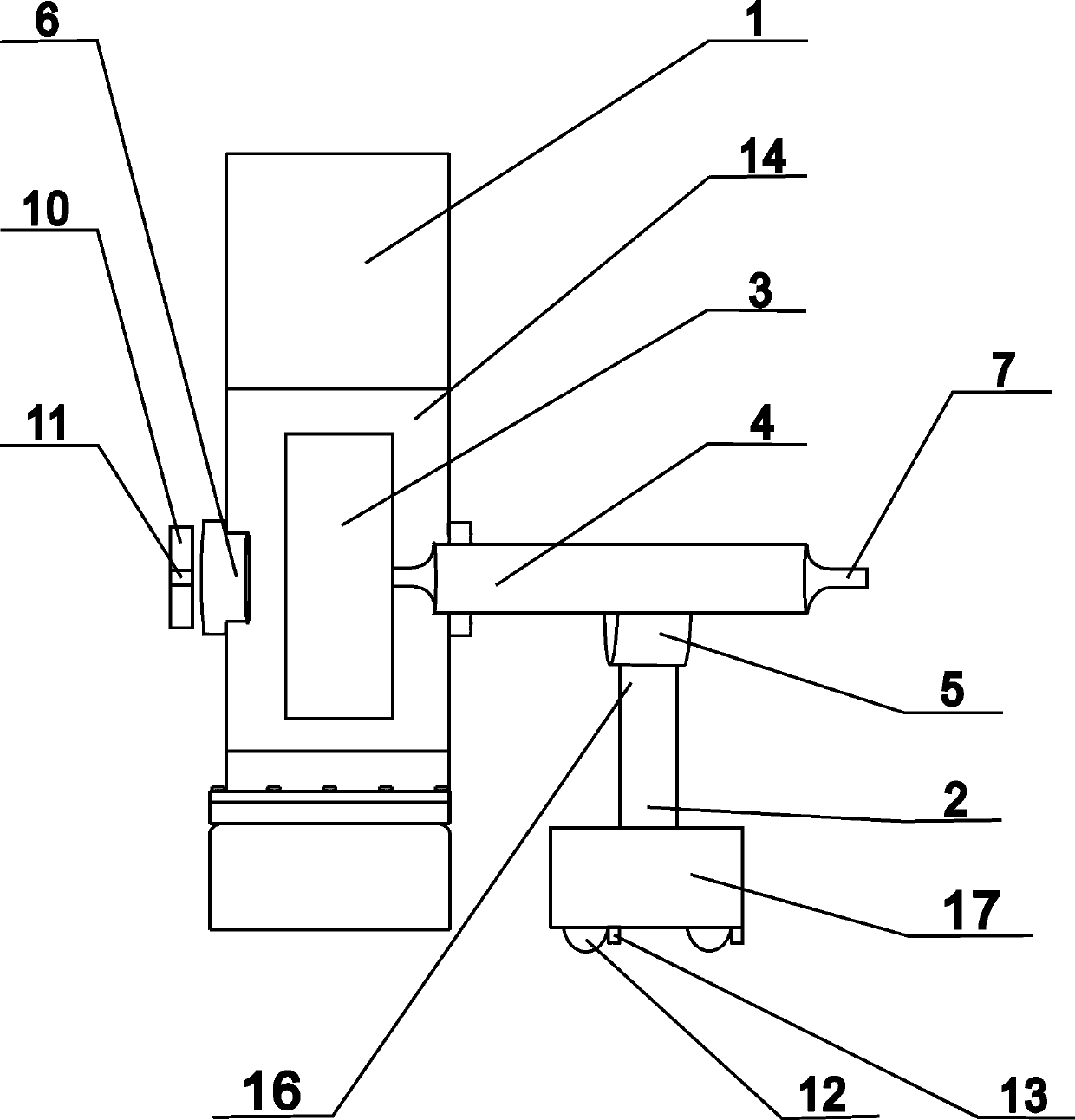

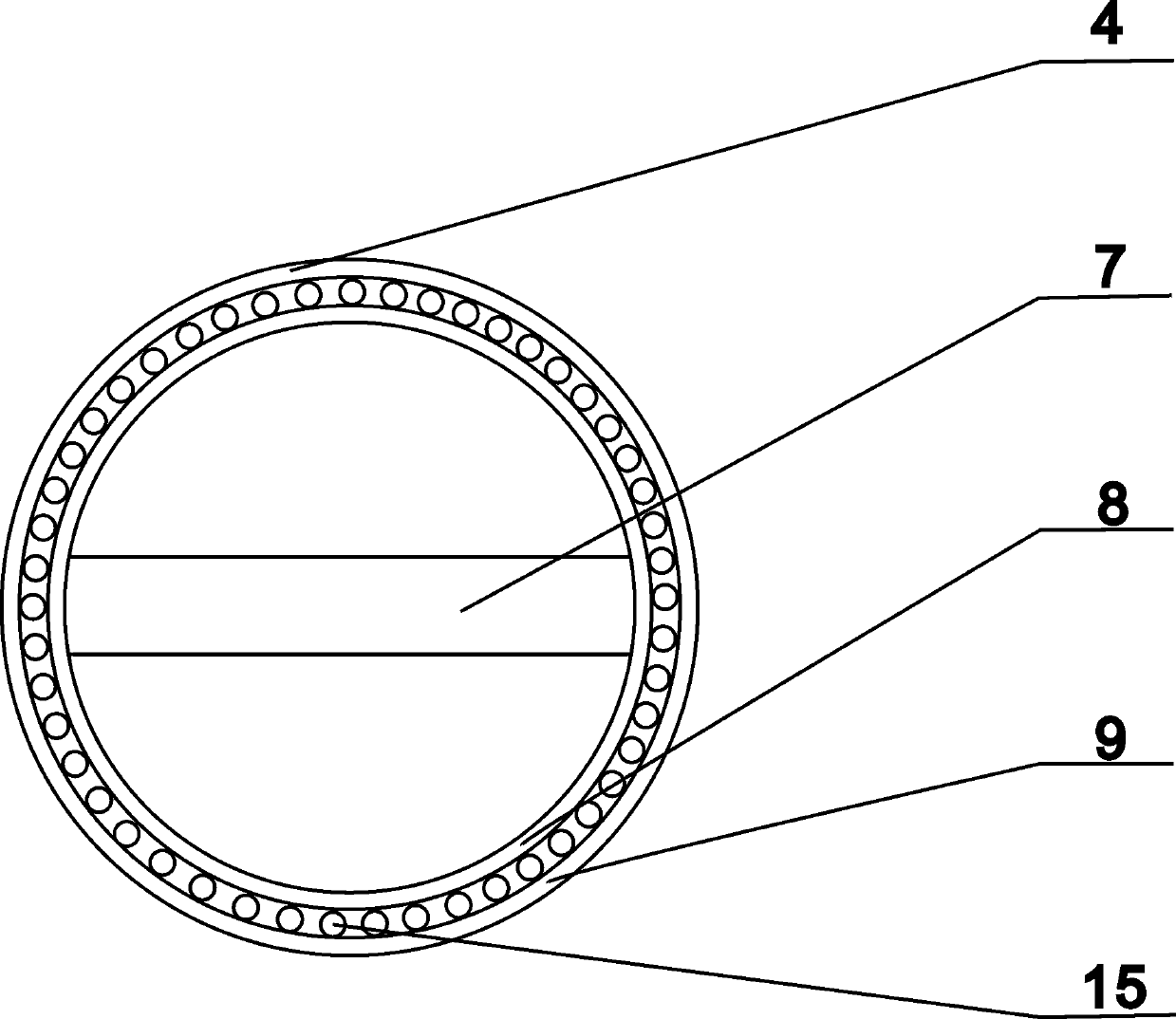

[0018] As shown in the figure, a pre-winding device for winding adhesive tape includes a column 1, a bracket 2, an adhesive tape 3, and a rotating shaft 4; the column 1 is arranged on the right side, and a rotating shaft 4 is arranged laterally at the lower part of the column 1, and the rotating shaft 4 passes through the column horizontally 1. A tape placement port 14 is provided on the right side of the column 1; the bracket 2 is composed of a support bracket 5, a roller 12, a roller locking device 13, a support rod 16, and a support seat 17. The support bracket 5 is arranged on the side of the support rod 16. The upper part is fixedly connected with the support rod 16, the bottom of the support rod 16 is provided with a support base 17, the support base 17 is fixedly connected with the upper support rod 16, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com