Production technique for hot filling beverage bottle

A production process and beverage bottle technology, applied in the field of liquid storage and transportation, can solve problems such as harm to human health, inability to sterilize beverages such as fruit juice, and poor temperature resistance of beverage bottles, and achieve the effect of improving sterilization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

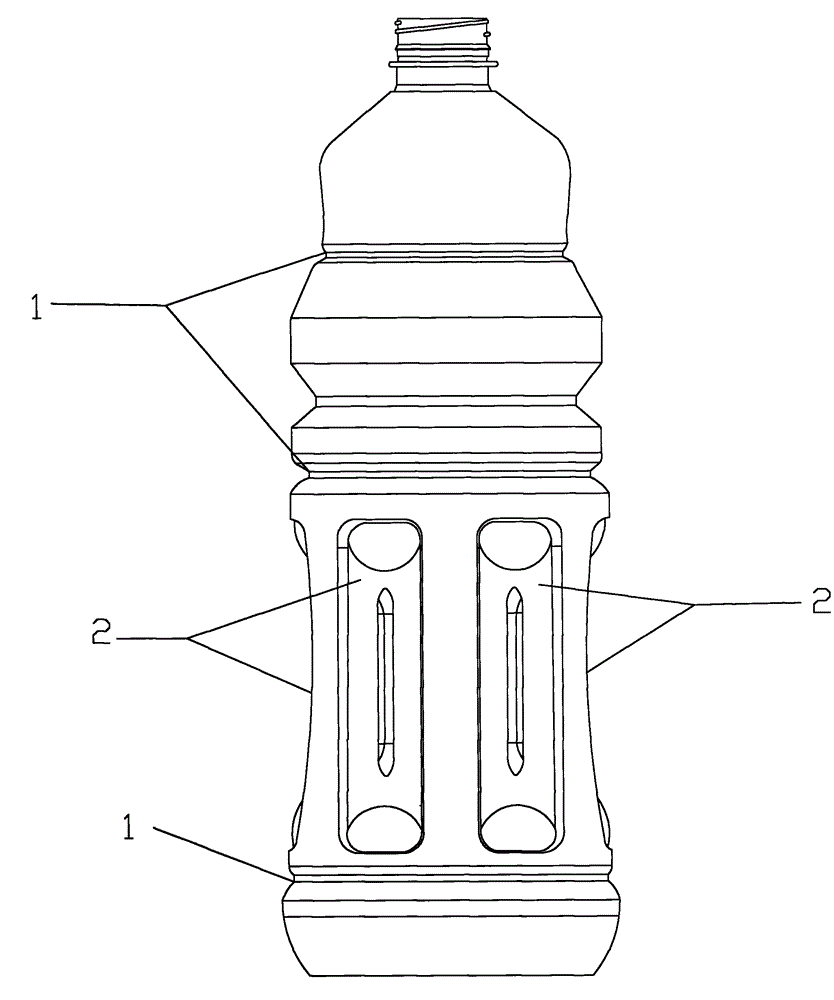

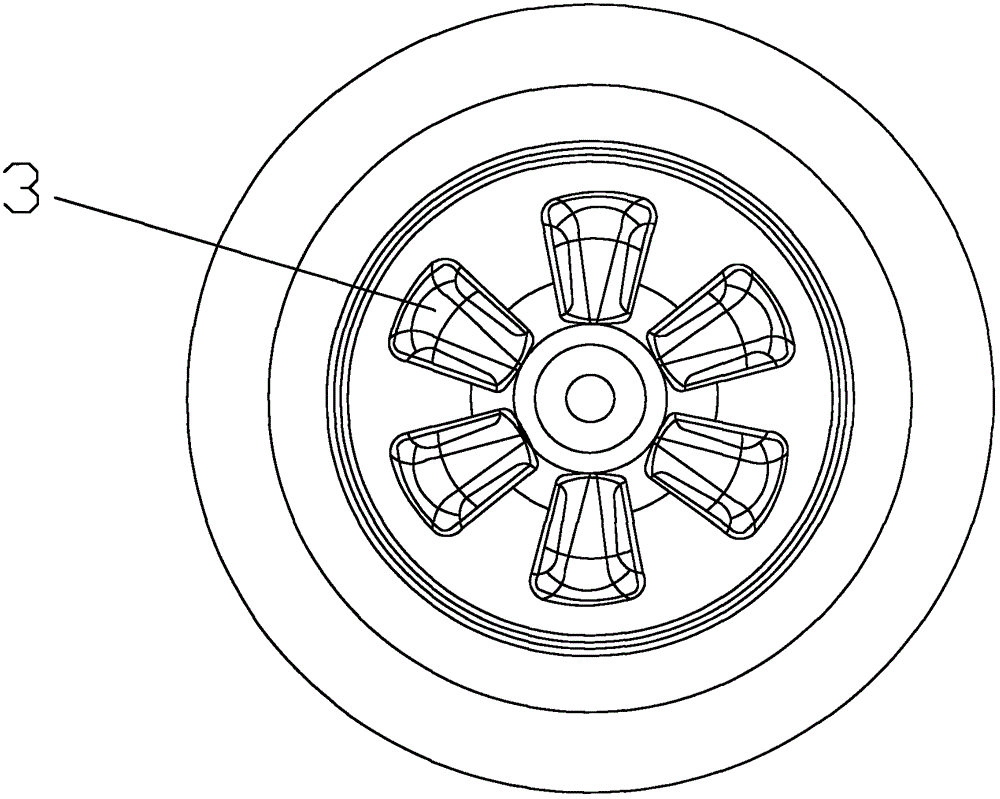

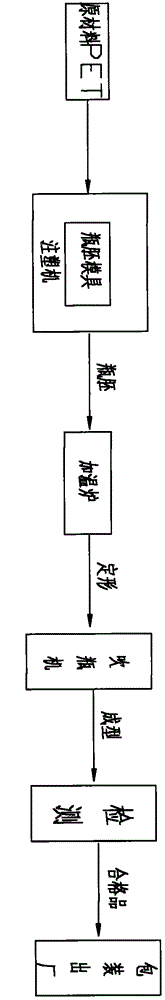

[0022] like Figure 1~3 As shown, the invention provides a kind of production technology of hot filling beverage bottle, it is characterized in that, comprises the following steps:

[0023] (1) Preform mold: 3 barrier rings and 6 negative pressure blocks are designed on the bottle body to offset the heat and cold shrinkage during the filling process, so that the bottle will not be deformed; 6 concave-convex blocks are designed on the bottom of the bottle , so that the bottom of the bottle is heated and protrudes outward during the filling process, so that the bottle will not be deformed;

[0024] (2) Preform: the raw material PET plastic is passed through an injection molding machine and a preform mold to form a preform;

[0025] (3) Heating and setting: the preform is heated through a heating furnace in 6 stages, the temperature of the first stage is 93°C, the temperature of the second stage is 83°C, the temperature of the third stage is 53°C, the temperature of the fourth s...

Embodiment 2

[0030] like Figure 1~3 As shown, the invention provides a kind of production technology of hot filling beverage bottle, it is characterized in that, comprises the following steps:

[0031] (1) Preform mold: 3 barrier rings and 6 negative pressure blocks are designed on the bottle body to offset the heat and cold shrinkage during the filling process, so that the bottle will not be deformed; 6 concave-convex blocks are designed on the bottom of the bottle , so that the bottom of the bottle is heated and protrudes outward during the filling process, so that the bottle will not be deformed;

[0032] (2) Preform: the raw material PET plastic is passed through an injection molding machine and a preform mold to form a preform;

[0033] (3) Heating and setting: the preform is heated through a heating furnace in 6 stages, the temperature of the first stage is 98°C, the temperature of the second stage is 89°C, the temperature of the third stage is 59°C, the temperature of the fourth s...

Embodiment 3

[0038] like Figure 1~3 As shown, the invention provides a kind of production technology of hot filling beverage bottle, it is characterized in that, comprises the following steps:

[0039] (1) Preform mold: 3 barrier rings and 6 negative pressure blocks are designed on the bottle body to offset the heat and cold shrinkage during the filling process, so that the bottle will not be deformed; 6 concave-convex blocks are designed on the bottom of the bottle , so that the bottom of the bottle is heated and protrudes outward during the filling process, so that the bottle will not be deformed;

[0040] (2) Preform: the raw material PET plastic is passed through an injection molding machine and a preform mold to form a preform;

[0041] (3) Heating and setting: the preform is heated through a heating furnace in 6 stages, the temperature of the first stage is 95°C, the temperature of the second stage is 86°C, the temperature of the third stage is 56°C, the temperature of the fourth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com