Vibratory broaching device and method based on 2d valve-controlled electro-hydraulic excitation

An electro-hydraulic excitation and valve-controlled technology, applied in broaching device, fluid pressure actuating device, broaching machine, etc., can solve the problems of short broaching tool life and low broaching accuracy, reduce tool wear and improve broaching. The effect of cutting quality and reducing broaching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

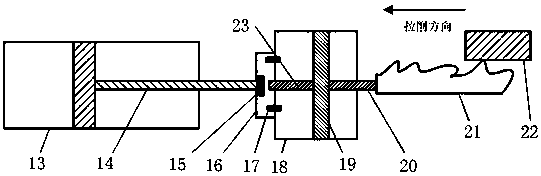

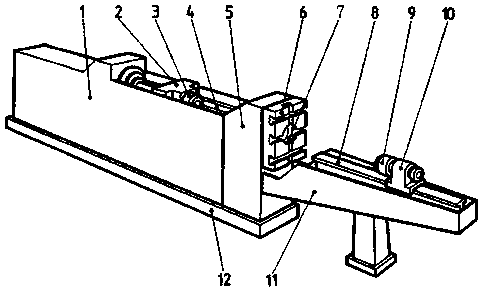

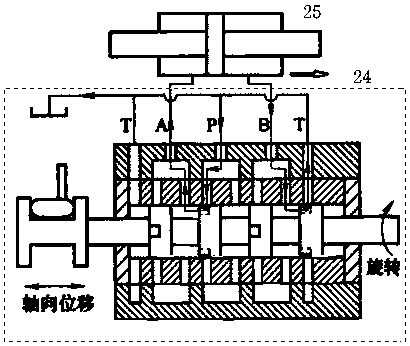

[0041] Such as Figure 1-2 As shown, the vibration broaching device based on 2D valve-controlled electro-hydraulic excitation of the present invention includes a hydraulic horizontal inner broaching machine, a 2D valve-controlled electro-hydraulic vibration exciter and a broach 21; figure 2As shown, the broaching machine used in the present invention is a hydraulic horizontal broaching machine, which is composed of a bed 1, a bed platform 5, an auxiliary bed 11, a base 12, a workbench 6, a main sliding plate guide rail 4, and an auxiliary sliding plate guide rail 8 , the main tool holder 2, the main card cutter body 3, the auxiliary tool holder 10, and the auxiliary card cutter body 9, the workbench 6 is a structural part of the broaching machine, and plays a supporting role; the main slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com