Non-uniform honeycomb type denitration catalyst and preparation method thereof

A denitration catalyst, honeycomb-type technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of reducing SO2 oxidation rate, low cost, and reducing SO3 production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation carrier:

[0042] 1) mixing: in parts by mass, take TiO 2 100 parts of powder, 40 parts of deionized water, 5 parts of organic binder, 4 parts of plasticizer, 2 parts of extrusion aid, 20 parts of ammonia water, and 6 parts of glass fiber are fully mixed and stirred to obtain a plastic colloid;

[0043] 2) Extrusion: Extrude the plastic colloid through a thin-walled mold to obtain a shaped honeycomb body;

[0044] 3) Drying: drying the honeycomb body at 70°C for 144 hours;

[0045] 4) Calcination: calcining the dried honeycomb green body at a temperature of 600°C for 5 hours to obtain a carrier.

[0046] To prepare the active solution:

[0047] According to the catalyst containing 1% active component V 2 o 5 , 1.2% WO 3 Prepare vanadium oxalate solution and ammonium metatungstate solution, mix and stir the two solutions evenly, based on the mass ratio of citric acid to active solution, then add 0.5% citric acid and stir evenly for later use.

[0048] ...

Embodiment 2

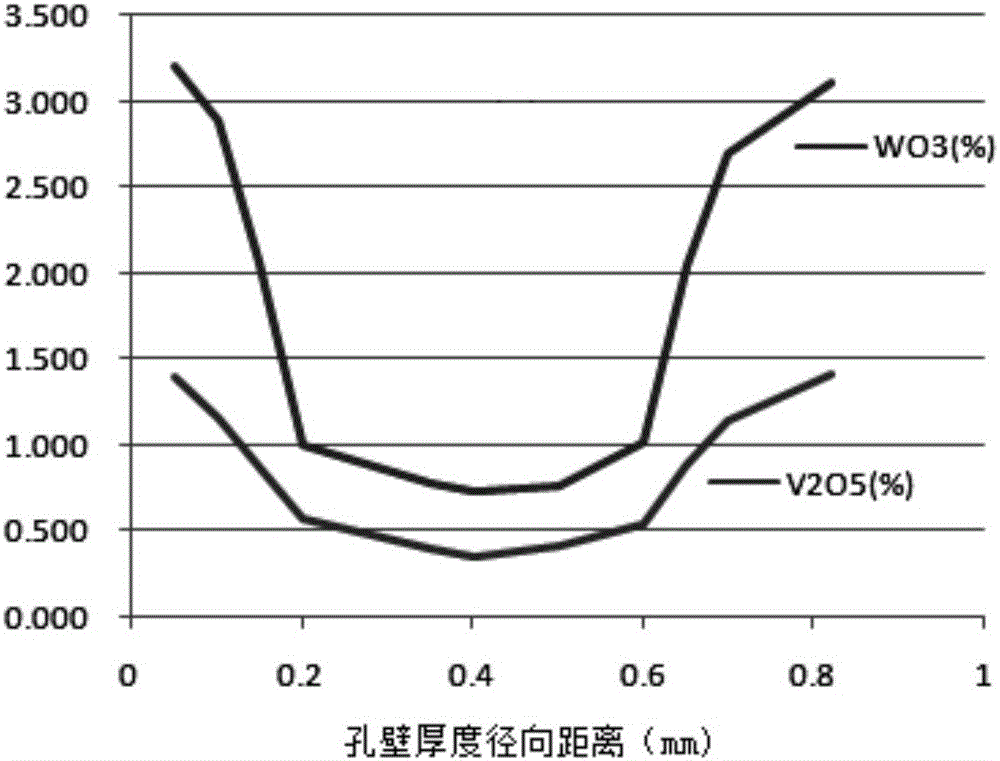

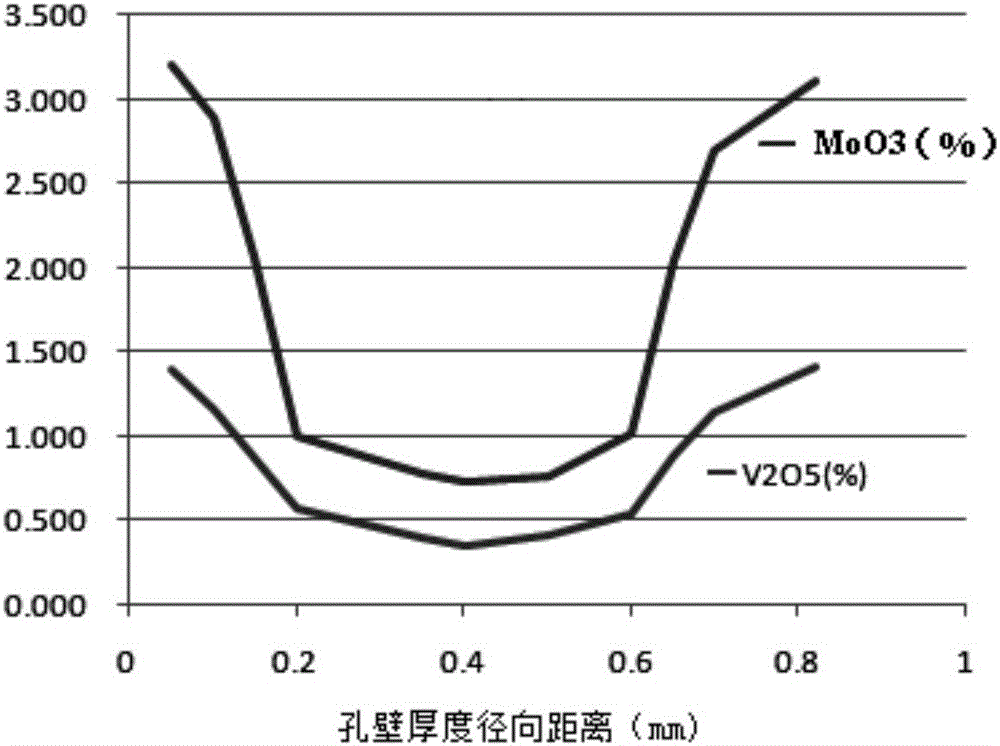

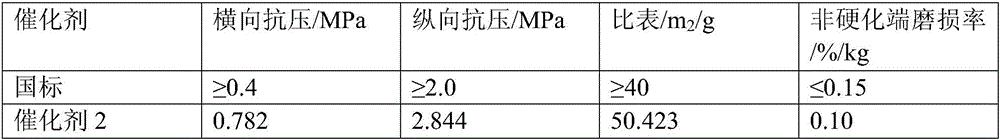

[0052] The immersion time is 30min, according to the catalyst containing 1% V of active components in the synthesis 2 o 5 , 1.8% WO 3 Benchmark preparation vanadium oxalate solution and ammonium metatungstate solution, other processes and conditions such as example 1, make catalyst 2, wherein WO 3 content of 1.8%, V 2 o 5 The content is 1%.

Embodiment 3

[0054] No competitive adsorbent is added, the impregnation time is 10min, according to the catalyst containing 1% of active components V 2 o 5 , 1.5% WO 3 Benchmark preparation vanadium oxalate solution and ammonium metatungstate solution, other processes and conditions such as example 1, make catalyst 3, wherein WO 3 content of 1.5%, V 2 o 5 The content is 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com