Sulfur granule modifying agent for complexing iron desulphurization liquid and use method thereof

A technology of sulfur particles and desulfurization liquid, which is applied in separation methods, chemical instruments and methods, and sulfur preparation/purification, etc., can solve the problems of insignificant improvement effect, small sulfur particles, and easy generation of sulfur blockage, and achieves reduction of suspended sulfur content, easy settling, good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

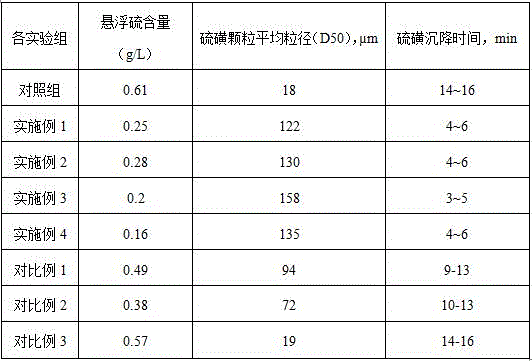

Examples

Embodiment 1

[0017] A sulfur particle modifier for complex iron desulfurization liquid, consisting of the following components in mass percentage:

[0018] Nonionic Surfactant: Nonylphenol Ethoxylate 10%

[0019] Flocculant: sodium polystyrene sulfonate 1‰, average molecular weight 50,000

[0020] Humectant: Glycerin 10%

[0021] Silicone oil defoamer 2ppm,

[0022] The rest is water.

[0023] Preparation method: Dissolve the nonylphenol polyoxyethylene ether, sodium polystyrene sulfonate, glycerin and silicone oil defoamer in the above weight percentage in water, stir until completely dissolved, and obtain the sulfur particle modifier, which is transparent .

[0024] Method of use: The sulfur particle modifier is added in an amount of 50ppm, which is added to the complexed iron desulfurization solution. The iron ion concentration in the complexed iron desulfurization solution is 0.01mol / L, and the complexing agent concentration is 0.01mol / L. The mixed liquid is passed into the mixed ...

Embodiment 2

[0026] A sulfur particle modifier for complex iron desulfurization liquid, consisting of the following components in mass percentage:

[0027] Nonionic Surfactant: Octylphenol Ethoxylate 18%

[0028] Flocculant: sodium polystyrene sulfonate 2‰, average molecular weight 200,000

[0029] Wetting agent: Macrogol 400 and Glycerin 15%

[0030] Silicone oil defoamer 20ppm,

[0031] The rest is water.

[0032] Preparation method: Dissolve the octylphenol polyoxyethylene ether, sodium polystyrene sulfonate, polyethylene glycol 400, glycerin, and silicone oil defoamer in water in the above weight percentage, and stir until completely dissolved to obtain modified sulfur particles. Agent, transparent.

[0033] Method of use: The sulfur particle modifier is added in an amount of 30ppm, which is added to the complex iron desulfurization solution. The iron ion concentration in the complex iron desulfurization solution is 0.01mol / L, and the complexing agent concentration is 0.01mol / L. T...

Embodiment 3

[0035] A sulfur particle modifier for complex iron desulfurization liquid, consisting of the following components in mass percentage:

[0036] Non-ionic surfactant: fatty alcohol polyoxyethylene ether 30%

[0037] Flocculant: sodium polystyrene sulfonate 1.5‰, average molecular weight 150,000

[0038] Wetting agent: Macrogol 200 and Propylene Glycol 10%

[0039] Silicone oil defoamer 10ppm,

[0040] The rest is water.

[0041] Preparation method: Dissolve the fatty alcohol polyoxyethylene ether, sodium polystyrene sulfonate, polyethylene glycol 200, propylene glycol, and silicone oil defoamer in the above weight percentages in water, stir until completely dissolved, and obtain modified sulfur particles agent, transparent.

[0042] Method of use: The sulfur particle modifier is added in an amount of 80ppm, which is added to the complexed iron desulfurization solution. The iron ion concentration in the complexed iron desulfurization solution is 0.01mol / L, and the complexing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com