Edible mushroom inoculation equipment

A technology of edible fungi and equipment, applied in the field of edible fungus inoculation equipment, can solve the problems of heavy workload, low efficiency, and a large number of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

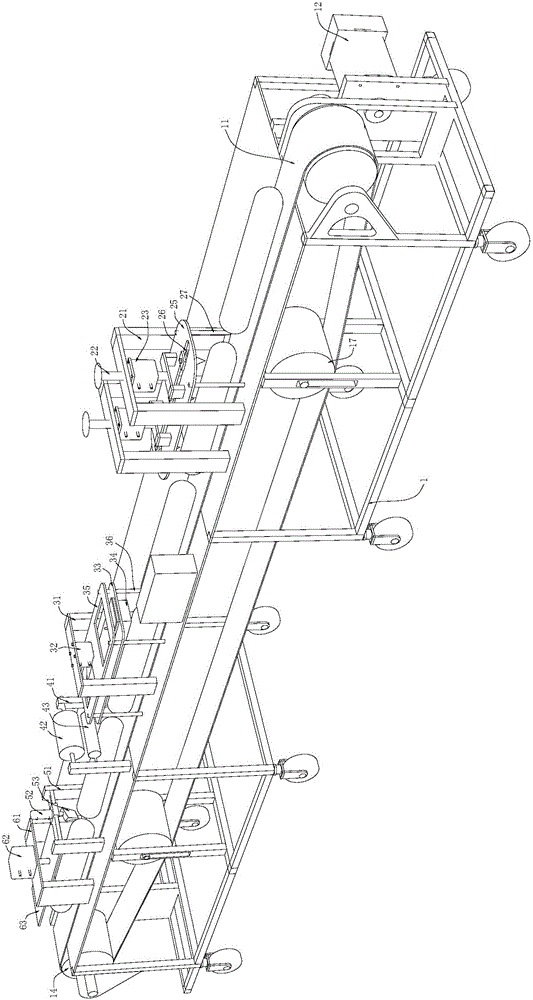

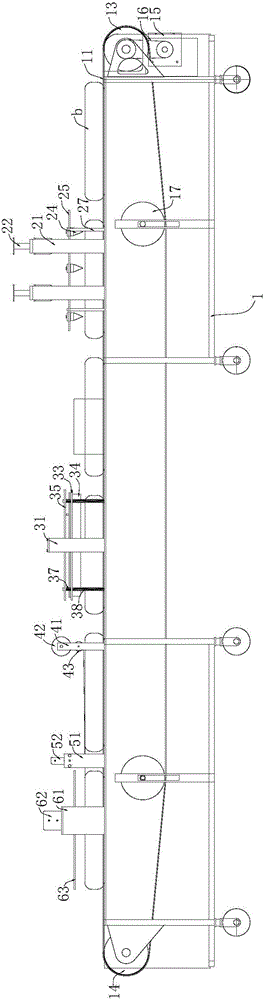

[0016] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as Figure 1~2 A kind of edible fungus inoculation equipment shown, comprises frame 1, and the conveyor belt 11 that is arranged on frame 1, and the drive motor 12 that drives conveyor belt 11 circular motion through transmission parts, and is used to adjust described conveyor belt 11 tightness tension parts. The conveyor belt 11 is positioned on the frame 1 by the driving shaft 13 and the driven shaft 14, the conveyor belt 11 is provided with several reference slots, the distance between adjacent reference slots is 500 mm, and the reference slots are used to place mushroom sticks b , monitoring points are installed every 500mm along the conveyor belt 11, and the monitoring points are used to detect the reference slot. Described drive motor 12 is connected with PLC, and PLC controls conveyer belt 11 motors and realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com