Die for bending-press forming

A stamping forming and mold technology, which is applied in the field of bending stamping molds, can solve the problems of difficult and efficient manufacturing, increased processing times, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

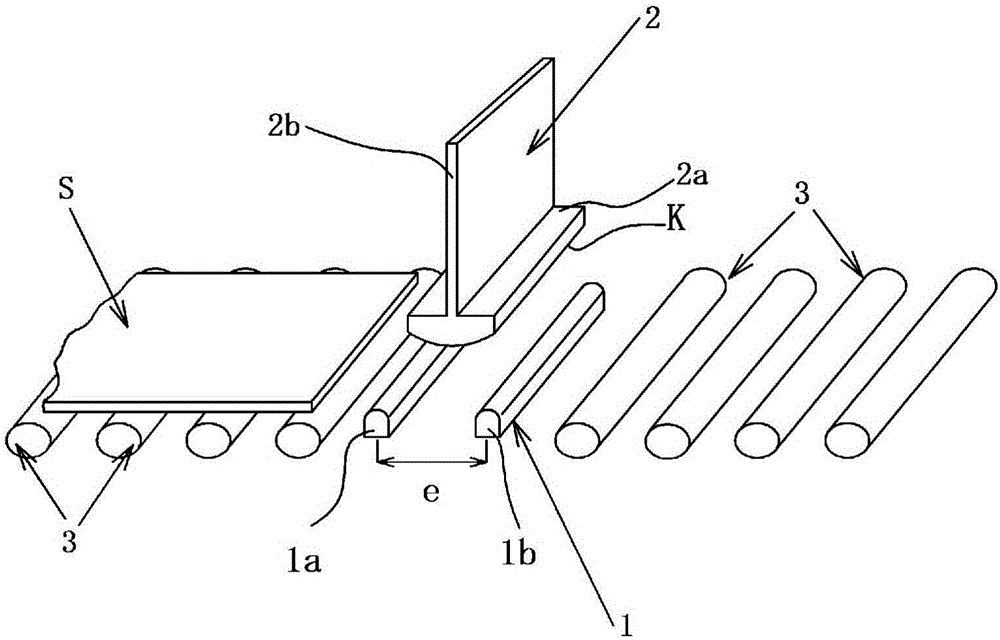

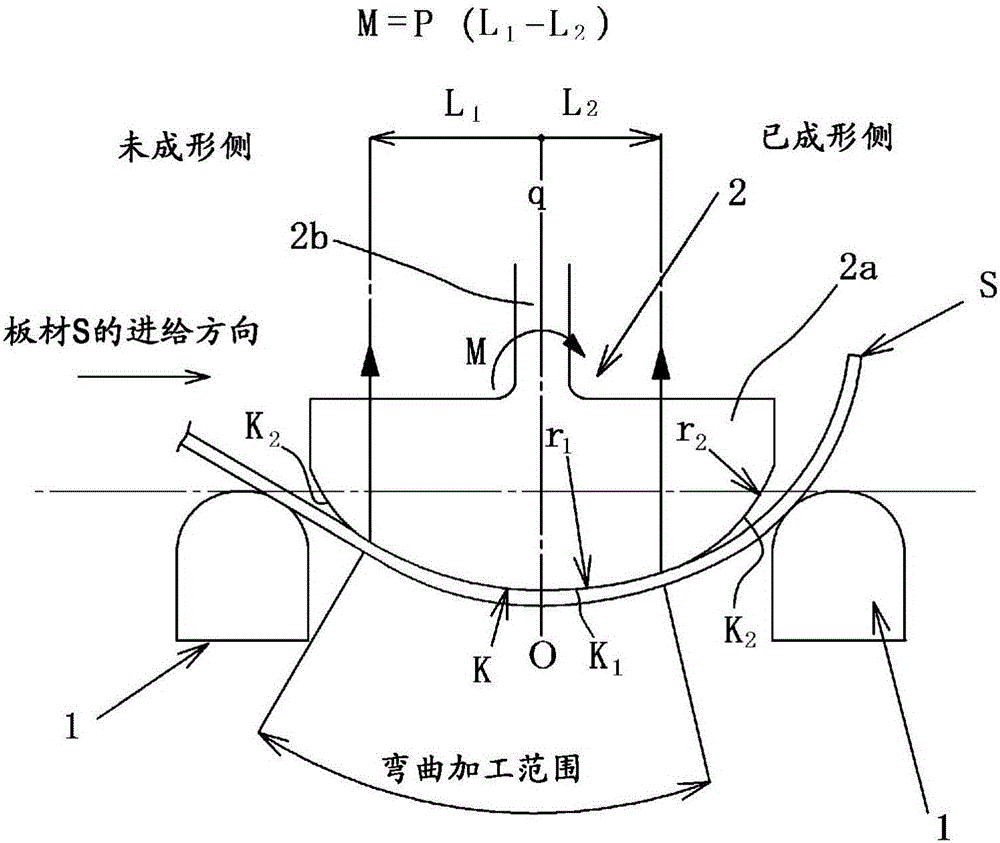

[0069] Prepare nine steel plates (steel type: API grade. X80) with a dimension of 3713mm along the feeding direction of the plate S, a plate thickness of 25.4mm, and a tensile strength of 745-757Mpa. Both end portions of each were bent so as to form an angle of 16.9 degrees within a range of 215 mm.

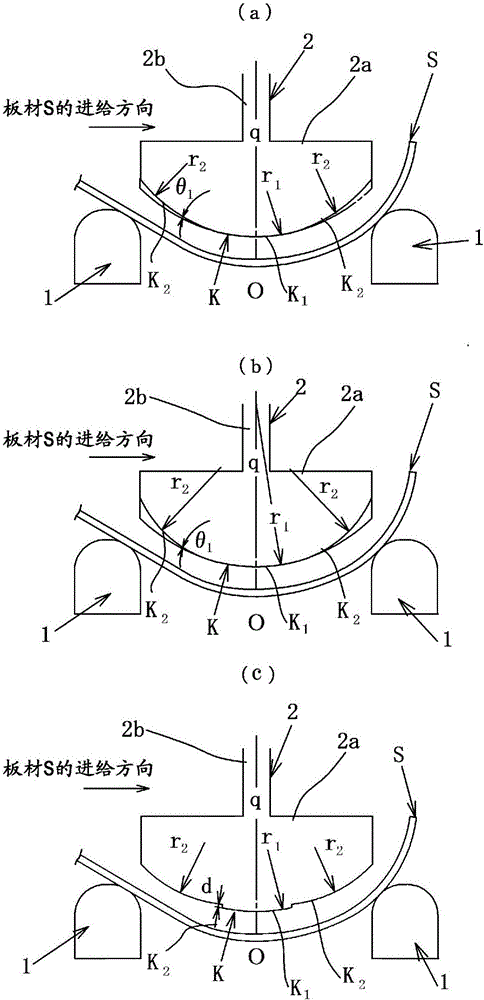

[0070] Next, take the position 1492 mm away from the center of the steel plate (the center of the dimension along the feed direction) on one side as the processing starting point, and set the feed pitch at 298 mm / time, the amount of bending forming at 29.6° / time, and the number of times of punching Three-point bending was performed from the left and right sides toward the center of the steel plate under the condition of five times.

[0071] In addition, the steel plate subjected to three-point bending was further subjected to one three-point bending (a total of eleven bendings) at the center, and after the interval between the butting portions of both ends of the steel plate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com