Method for preparing lithium carbonate by employing discarded lithium iron phosphate battery

A lithium iron phosphate battery and lithium carbonate technology, applied in lithium carbonate;/acid carbonate, battery recovery, recycling technology, etc., can solve the problem of low purity of lithium carbonate, low extraction efficiency, and high loss of lithium And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

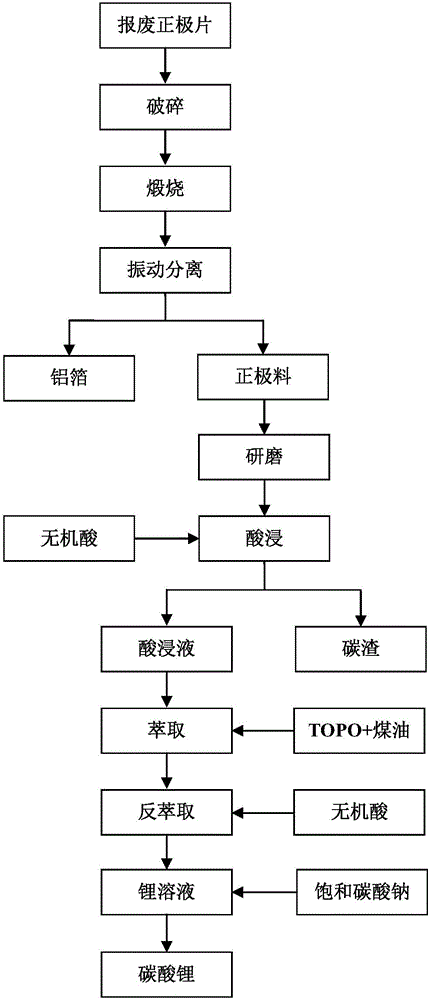

[0036] A method for reclaiming and preparing lithium carbonate from scrapped lithium iron phosphate battery positive plates, comprising the following steps:

[0037] (1) Use a crusher to crush the scrapped positive electrode sheet into a block positive electrode sheet smaller than 6cm;

[0038] (2) Calcining the block-shaped positive electrode sheet at 600°C for 1 hour in a high-temperature furnace with a nitrogen atmosphere;

[0039] (3) Use vibrating sieve to vibrate and separate the calcined block positive electrode sheet to obtain positive electrode material and recycled aluminum foil;

[0040] (4) Grinding the obtained positive electrode material with a grinder until the particle size is below 75 μm;

[0041] (5) After grinding, the positive electrode material was mixed with 5mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:6 (g:ml), and stirred and reacted at 70°C for 3 hours;

[0042] (6) Add a TOPO-kerosene extraction system with a volume ratio of 1:1 to ...

Embodiment 2

[0045] A method for reclaiming and preparing lithium carbonate from scrapped lithium iron phosphate battery positive plates, comprising the following steps:

[0046] (1) Use a crusher to crush the scrapped positive electrode sheet into a block positive electrode sheet smaller than 6cm;

[0047] (2) Calcinate the block-shaped positive electrode sheet at 500°C for 2 hours in a high-temperature furnace with a nitrogen atmosphere;

[0048] (3) Use vibrating sieve to vibrate and separate the calcined block positive electrode sheet to obtain positive electrode material and recycled aluminum foil;

[0049] (4) Grinding the obtained positive electrode material with a grinder until the particle size is below 75 μm;

[0050] (5) After grinding, the positive electrode material was mixed with 3mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:12 (g:ml), and stirred and reacted at 90°C for 1 hour;

[0051] (6) Add TOPO-kerosene extraction system with a volume ratio of 3:1 to t...

Embodiment 3

[0054] A method for reclaiming and preparing lithium carbonate from scrapped lithium iron phosphate battery positive plates, comprising the following steps:

[0055] (1) Use a crusher to crush the scrapped positive electrode sheet into a block positive electrode sheet smaller than 6cm;

[0056] (2) Calcinate the block-shaped positive electrode sheet at 400°C for 3 hours in a high-temperature furnace with a nitrogen atmosphere;

[0057] (3) Use vibrating sieve to vibrate and separate the calcined block positive electrode sheet to obtain positive electrode material and recycled aluminum foil;

[0058](4) Grinding the obtained positive electrode material with a grinder until the particle size is below 75 μm;

[0059] (5) After grinding, the positive electrode material was mixed with 1mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:15 (g:ml), and stirred and reacted at 80°C for 2 hours;

[0060] (6) Add a TOPO-kerosene extraction system with a volume ratio of 2:1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com