Light reflecting film surface layer, light reflecting film and manufacturing technologies therefor

A manufacturing process and surface layer technology, applied in the direction of optics, optical components, instruments, etc., can solve the problem of weakening the reflective effect of reflective film, and achieve the effect of eliminating adverse effects, permanent anti-dew, and good anti-dew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

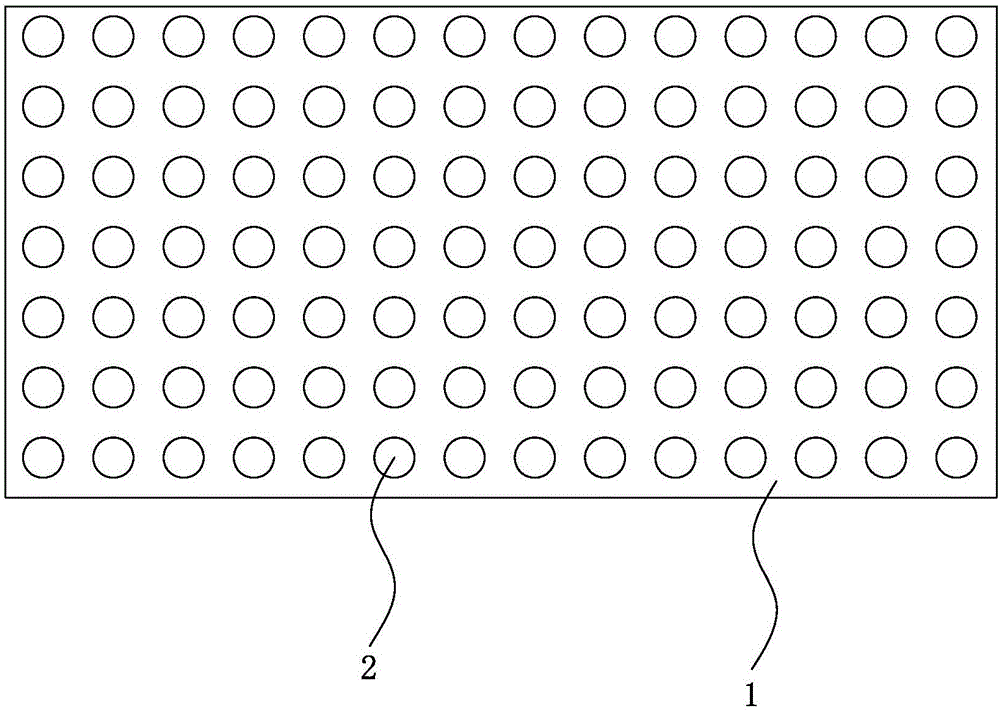

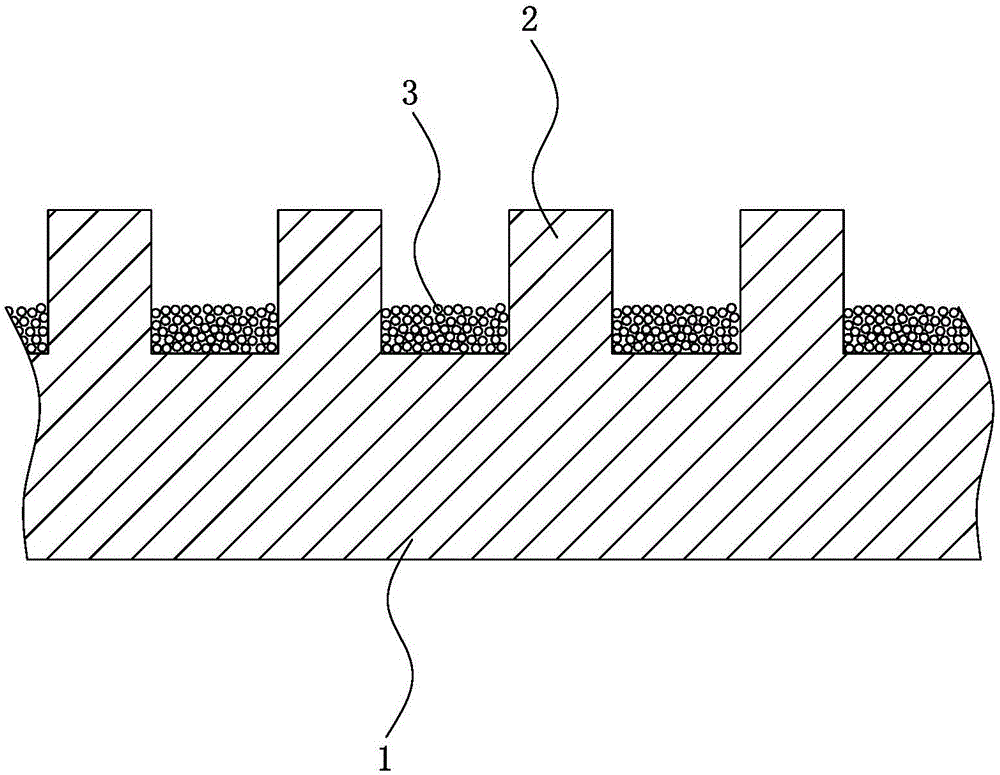

[0048] Embodiment one, such as figure 1 and figure 2 As shown, the surface layer of the reflective film of the present invention includes a substrate 1, and a plurality of light-transmitting raised structures 2 distributed uniformly at intervals are formed on the surface of the substrate 1, and the raised structures 2 have flat tops parallel to the surface of the substrate 1. On the other hand, the area of the surface of the substrate 1 without the raised structure 2 is coated with a hydrophilic layer 3, which is used to quickly guide water droplets to condense on the hydrophilic layer and protect the hydrophilic layer from being damaged during storage, transportation and use.

[0049] The substrate 1 and the protruding structure 2 are made of the same material, both being polymethyl methacrylate (PMMA) or polycarbonate (PC), and the protruding structure 2 is a cylinder whose cross-section can be circular or triangular. , rectangle or any polygon, in this embodiment, the c...

Embodiment 2

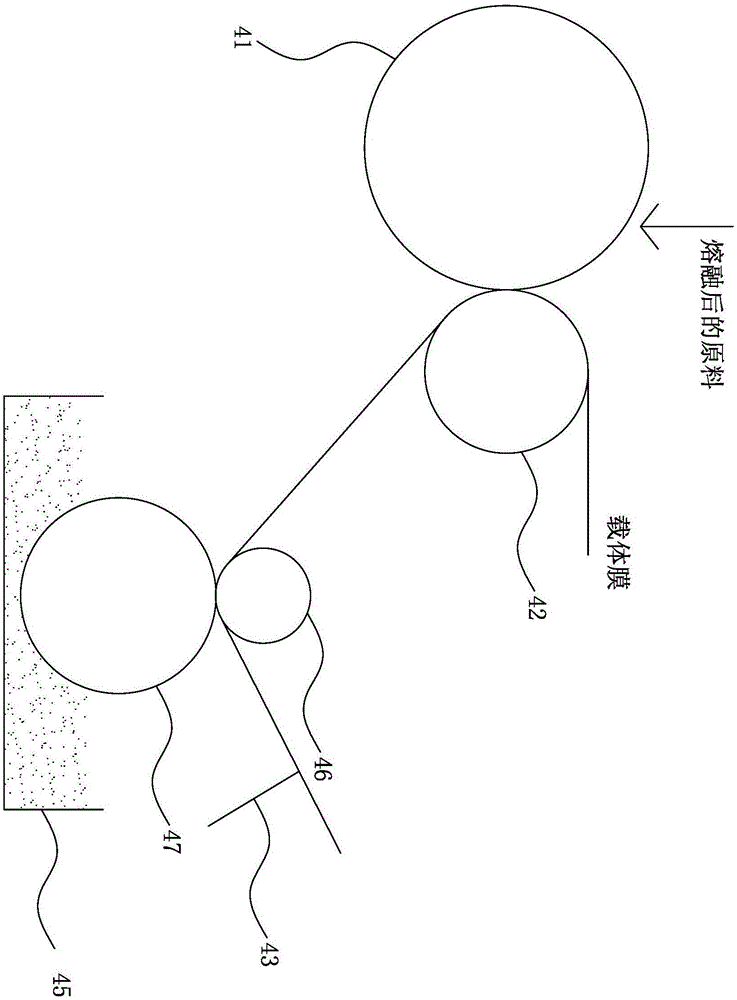

[0050] Embodiment two, the manufacturing device of the surface layer of the present embodiment is as image 3 and Figure 4 As shown, it includes a first heat roller 41 and a first pressure roller 42 arranged in parallel and opposite to each other and can be driven to rotate synchronously and reversely, a roller coating mechanism arranged on the output side of the first pressure roller 42, and a rubber coating mechanism arranged on the output side of the roller coating mechanism. Scraping sheet 43, the carrier film (PET film) that can not be thermally fused with PMMA colloidal particles is sandwiched between the first heat roll 41 and the first pressure roll 42 and conveyed, and the first heat roll 41 surface is uniformly spaced and distributed for forming convex Structured groove 44, the first pressure roller 42 is a hard rubber and plastic roller, the roller coating mechanism includes a trough 45, a second pressure roller 46 and a roller coating wheel 47 that are arranged in...

Embodiment 3

[0055] Embodiment three, the manufacturing device of the microprism reflective film of the present embodiment is as Figure 5 As shown, it includes a first heat roller 51 and a first pressure roller 52 arranged in parallel and opposite and can be driven to rotate synchronously and reversely, a second heat roller 53 and a second pressure roller 54 arranged in parallel and opposite and can be driven to rotate synchronously and reversely, The roller coating mechanism arranged on the output side of the first pressing roller 52, the rubber scraping blade 58 arranged on the output side of the roller coating mechanism, the traction roller 59 arranged on the output side of the rubber scraping blade 58, the second heating roller 53 and the second pressing roller 54 is arranged on the output side of the rubber scraping blade 58, and the carrier film (PET film) that cannot be thermally fused with the PMMA colloidal particles is clamped between the first heat roller 51 and the first pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com